My Ideas and Upgrades - Karen Taylor (formerly Ramel)

This page is a place for me to share ideas and upgrades that I’ve come up with.

Want to see what I’ve made on the CSM? Check out My Scrapbook page.

Want more supply info? See SUPPLIES I LIKE

Seeking a specific topic? You can additionally see the INDEX page under that category

CAST ON

For more info see this page on how to make your own Universal Bonnet or Cylinder Specific Cast On Bonnet (or buying one I made).

SPLIT-RING UNIVERSAL FLAT CAST ON BONNETS

Cylinder Specific Cast On Bonnets

Lighting

For more see SUPPLIES I LIKE

Machine Upgrades

Yarn Mast, Topper, Carriers and Heel Fork

Yarn Topper Brake Upgrade

to reduce yarn slipping

For clarity - when working on a CSM and using the Heel Spring either to tighten your regular knitting or to prevent yarn slack to be able to go in either direction to make a heel or toe, it’s not the Heel Spring that slips. It’s the contact pinching the yarn - the brake - that slips. So for this I added a plastic shrink wrap tube on the horizontal wire right beside the goal posts in this image and added heat to plastic coat the horizontal wire closest to the goal posts. When the plastic coated wire is engaged with the Heel Spring it will pinch the yarn better here at the brake 🙂

Easy and removable if it’s not for you.

This upgrade is better than my prior posted venture (the video) on the right posted on YouTube Sept 2020

Shareable link: https://youtu.be/ApP3Kc8F5cA

Use your machine as much as I do and get frustrated by the Heel Spring slippage on thinner yarns? Simply apply a heat shrink tube and gain a bit more grip where the metal brake wire hugs the yarn.

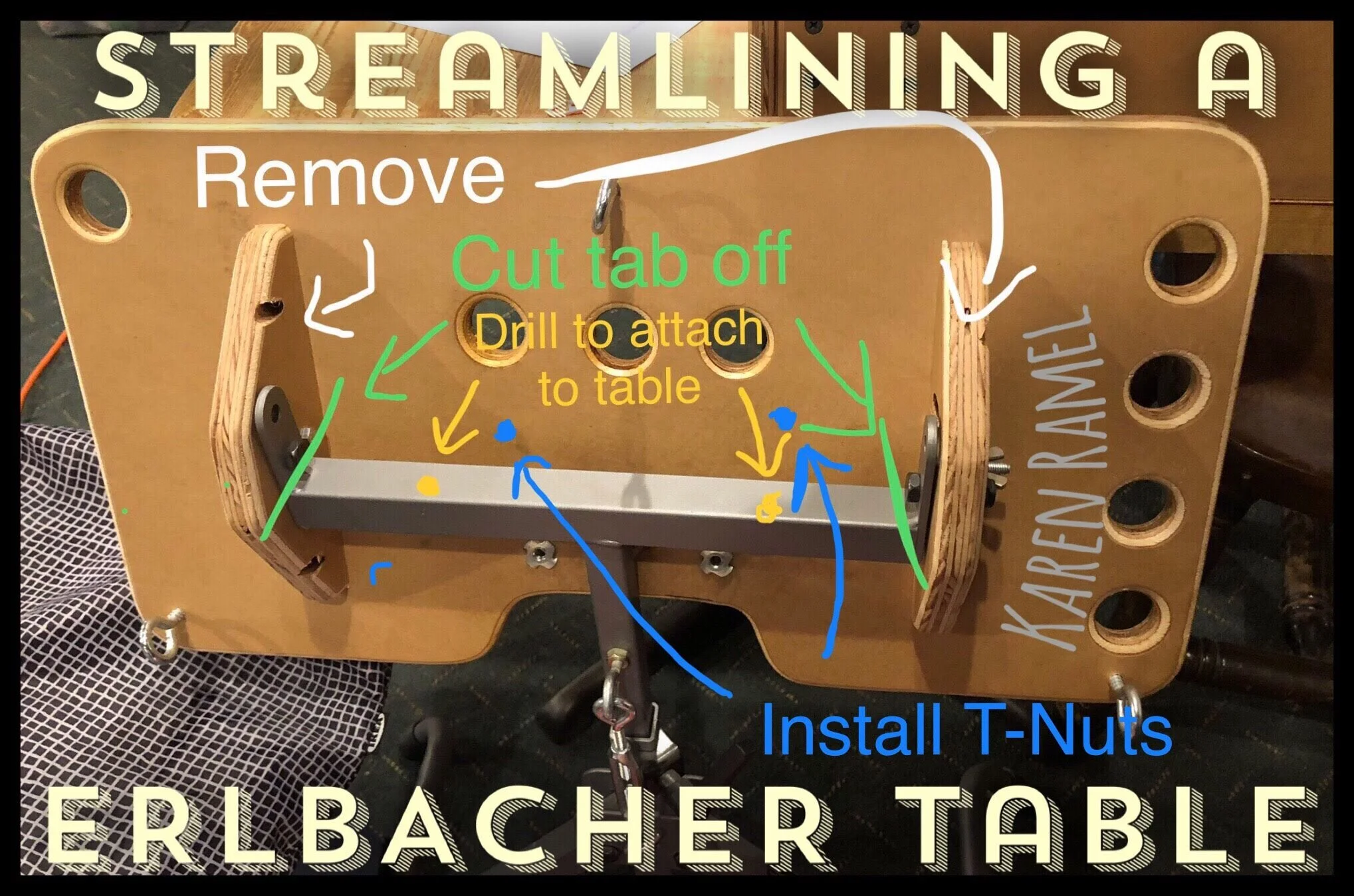

Machine and Table Upgrades and Modifications

Shareable YouTube link https://youtu.be/uqjRwf4h5i0

For more info on the Legare Platform 1.0 and 2.0 (including why it was inspired to be created) please see this blog post.

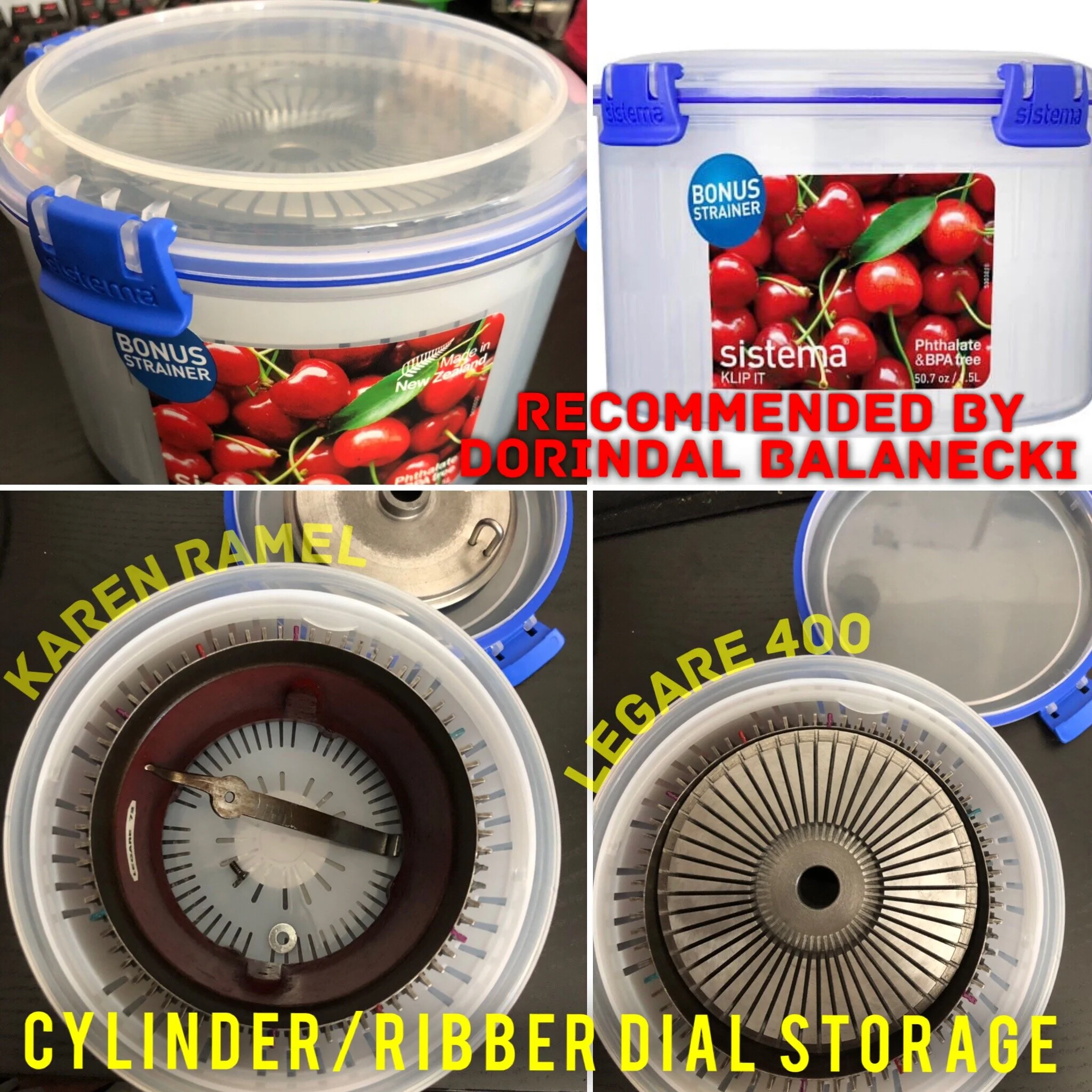

If you’re not using your Ribber now, consider keeping it dust free and off your table altogether by keeping it in a container see further down this page for what I do.

MARKETING

ADVERTISE and MARKET YOUR HOBBY/CRAFT!

MARKING

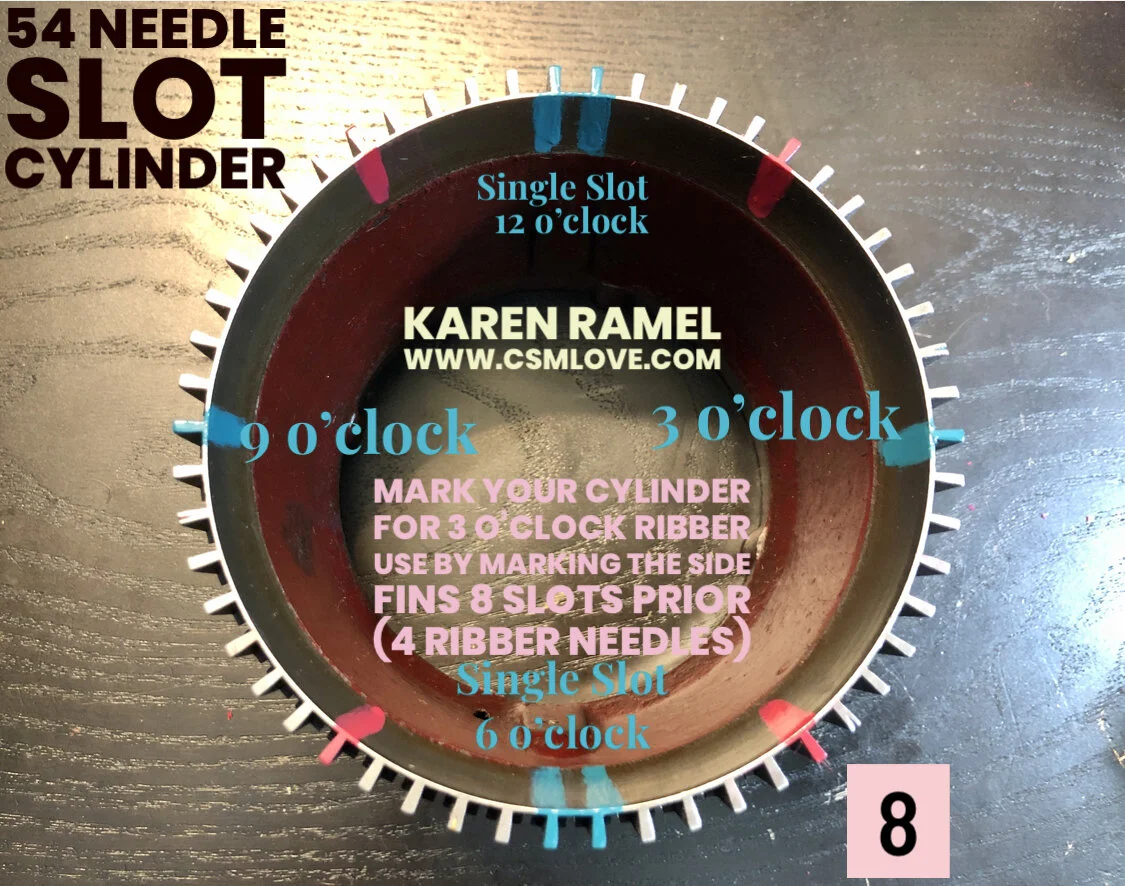

MARKING - CYLINDERs

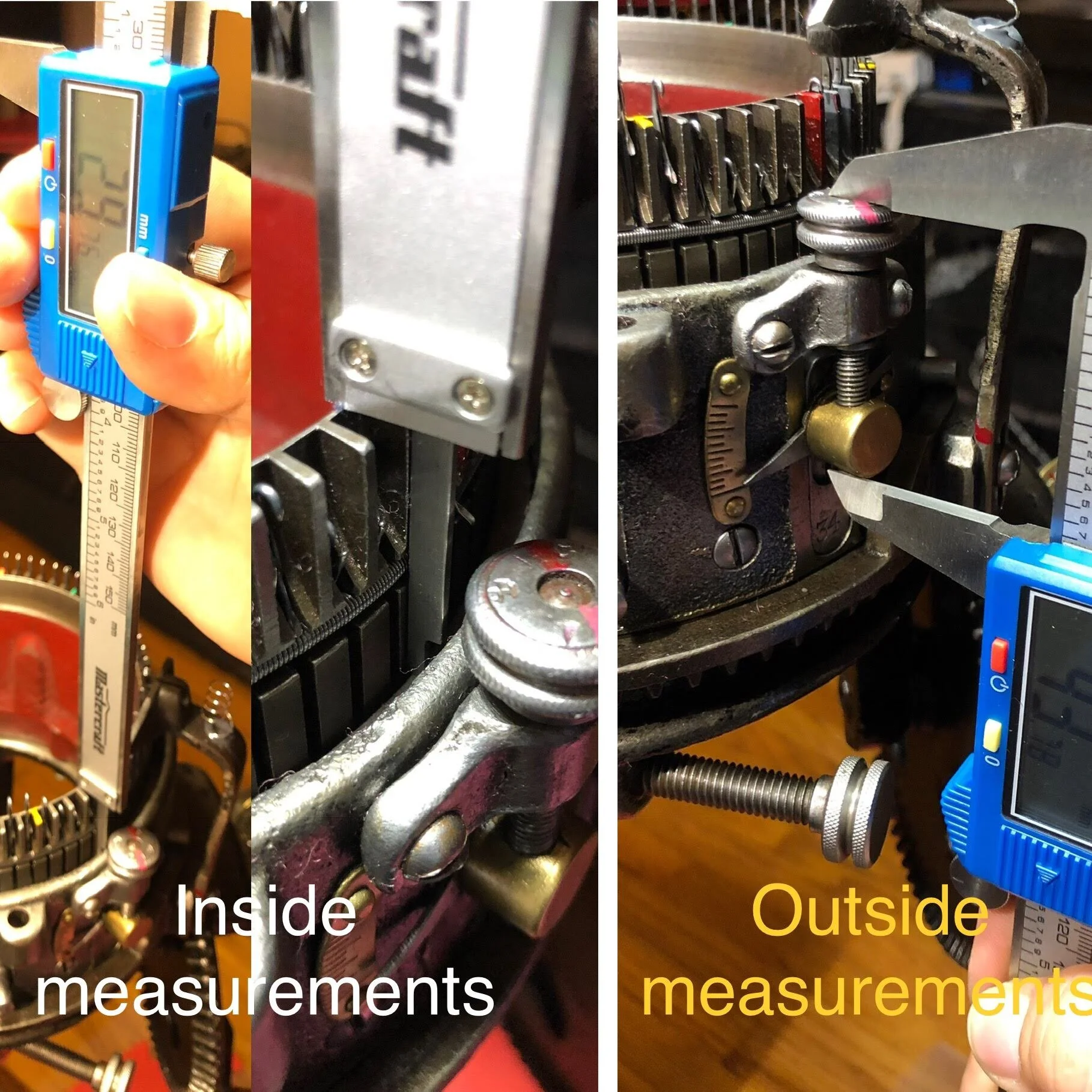

Marking your CSM cylinders? Mark the inside as well as this surface is hidden when working on the machine and won’t wear off with using your machine. We use nail polish predominately to mark certain points on our CSMs, however I’ve also found UV cured specialty polish (like those in nail salons) stays put much longer.

Eventually when your other marks in nail polish wear off you already have your reference points and can re-mark your cylinder as needed.

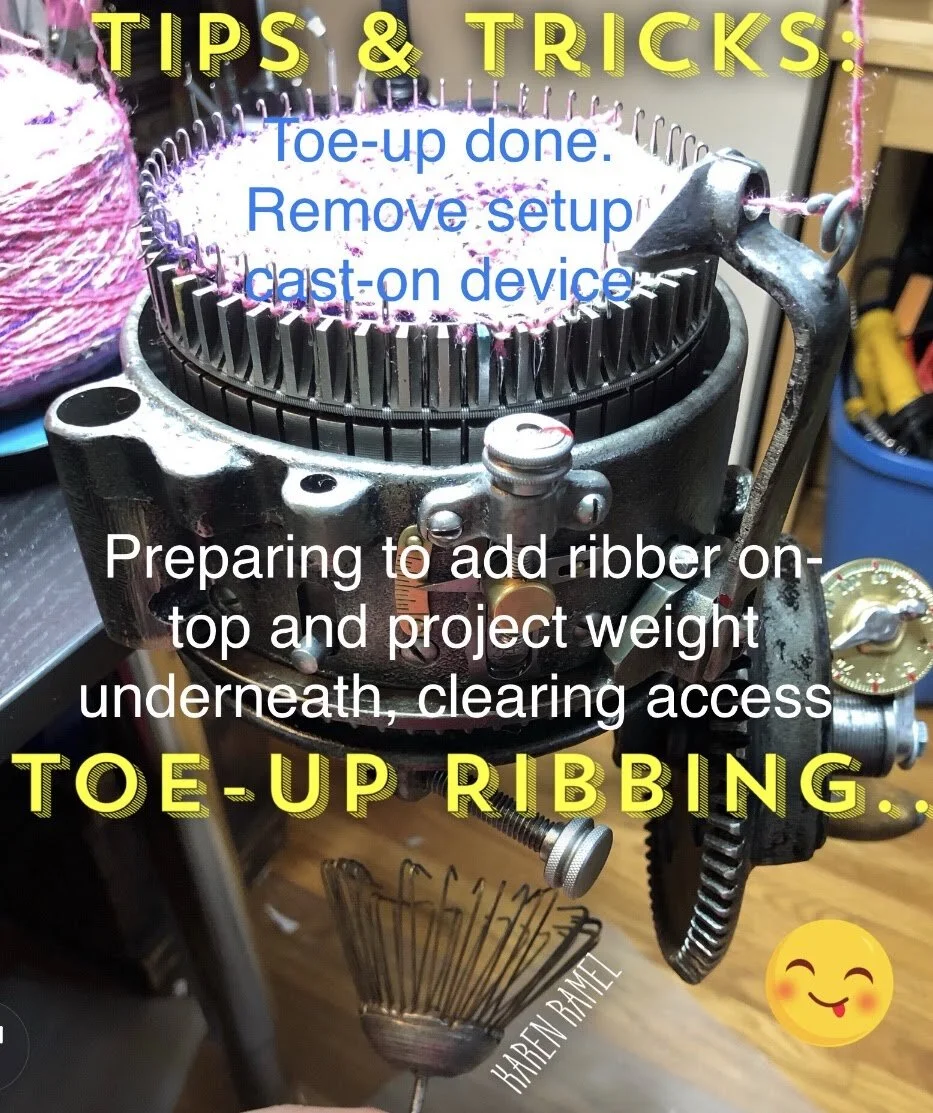

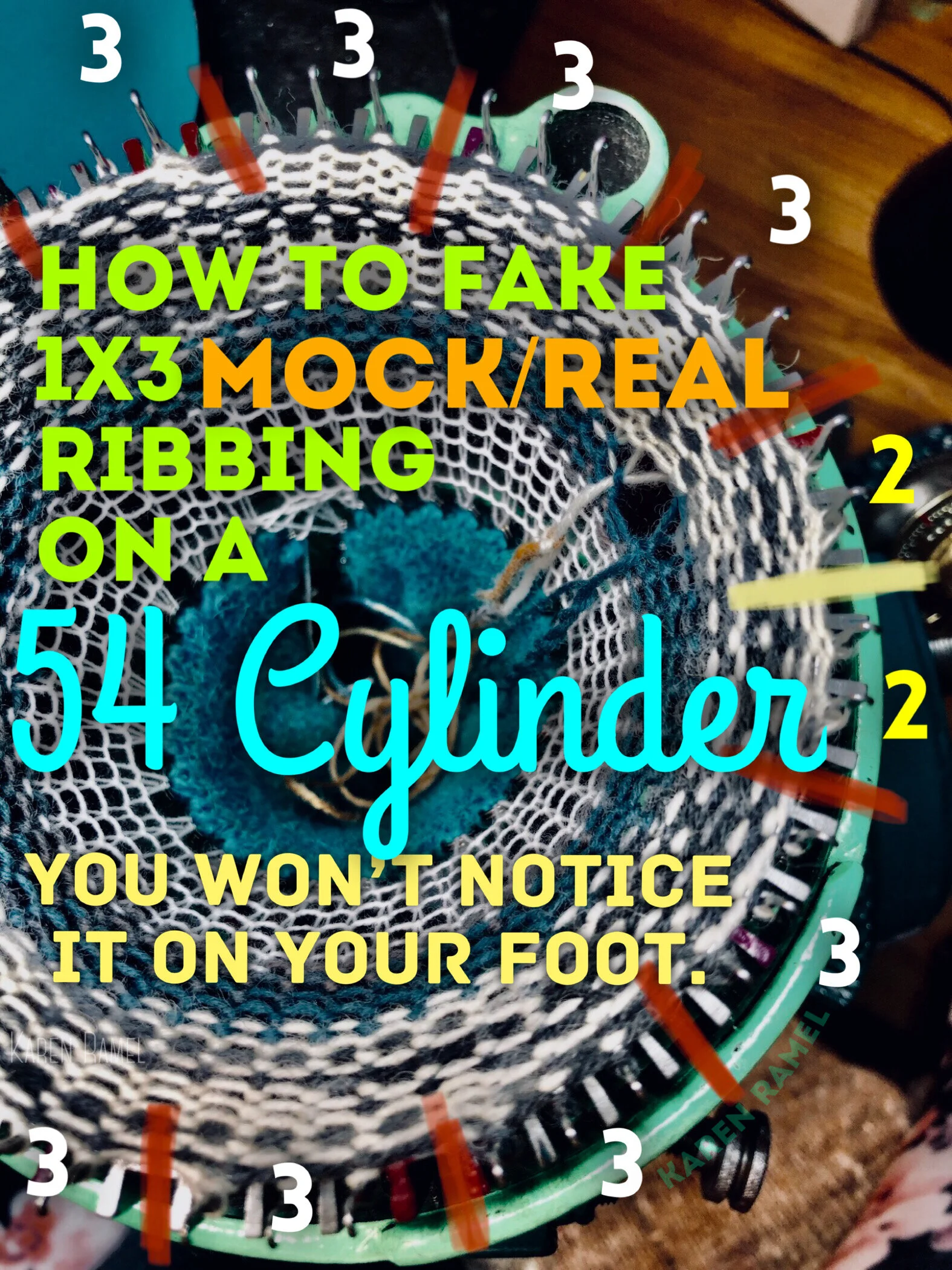

MARKING YOUR CYLINDERS FOR RIBBING

Having success on your machine with reproducing exact items means starting/ending or activating/de-activating the ribber at precise same points. As the ribber when activated or deactivated (in work or taken out of work) requires the distance of FOUR ribber needles, and because many (including myself) start the ribber at the 3 o’clock point on the cylinder, why not mark the cylinder for that? Here’s how that looks. :)

Mini-Mast for Colorwork

This version I built can manage four colors.

Powder Coated by Chambord CSM

For more information on MINI-MASTS see the INDEX PAGE under that category

ROW COUNTER INSTALLATION

Non-Standard Contact STYLE

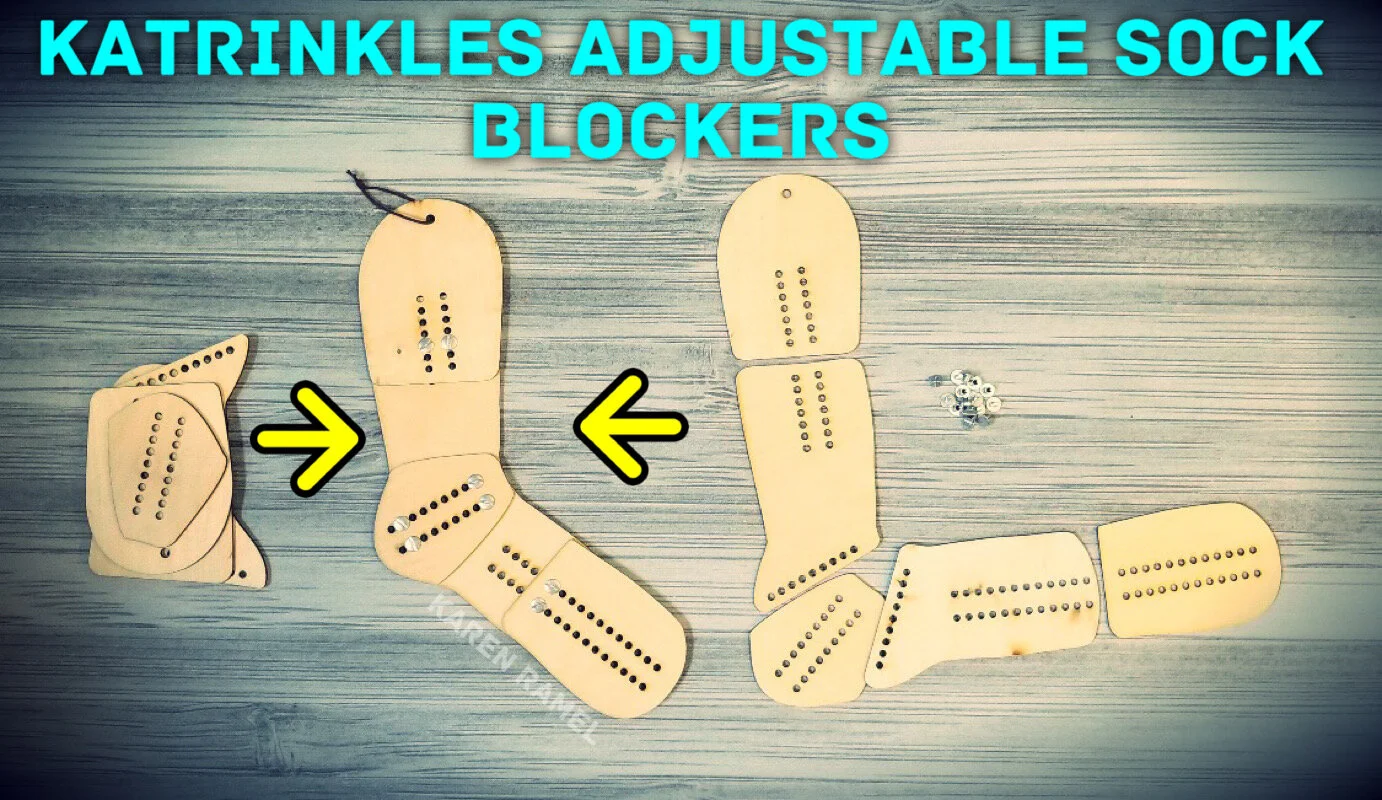

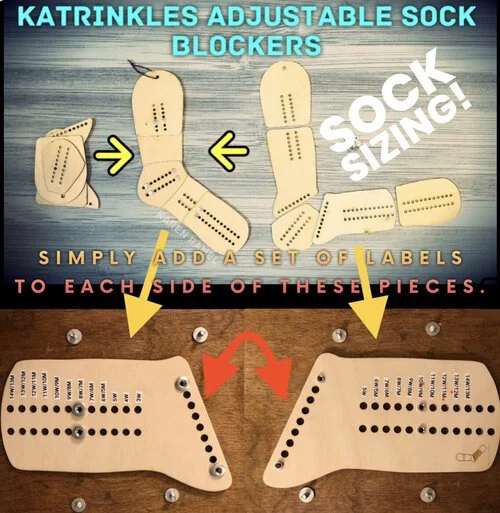

Sock Blockers THAT DO MORE!

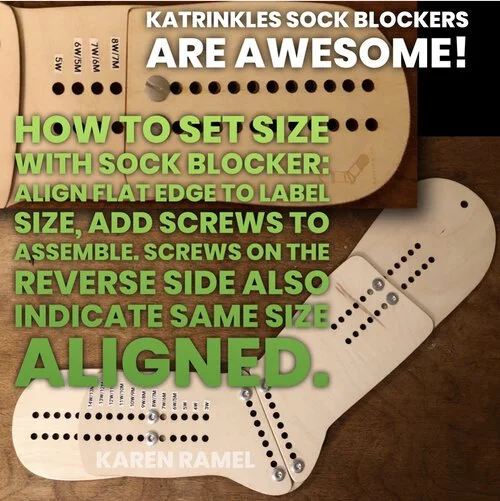

Historically we used Sock Blockers to shape a sock after washing. We now mostly use them for taking photos of our socks as it displays them nicely. I use mine for MORE. Use these wonderful Sock Blockers to take photos AND to confirm sock sizing on created socks! See the Katrinkles BLOG entry

Shown with Katrinkles Sock Blockers

Prior Adjustable Sock Blockers

These PRIOR sock blockers - the adjustable heart cut-out “Fish spine style” - were the first adjustable blockers that I had to upgrade in order to make them easier to use. (See video “Sock Block & Size) The upgrade I did added stability but didn’t help the uneven foot edges when used but did allowed them to stay assembled. The white Velcro strap I added was just used to keep the unique parts together. See the March 5 2020 Blog Entry.

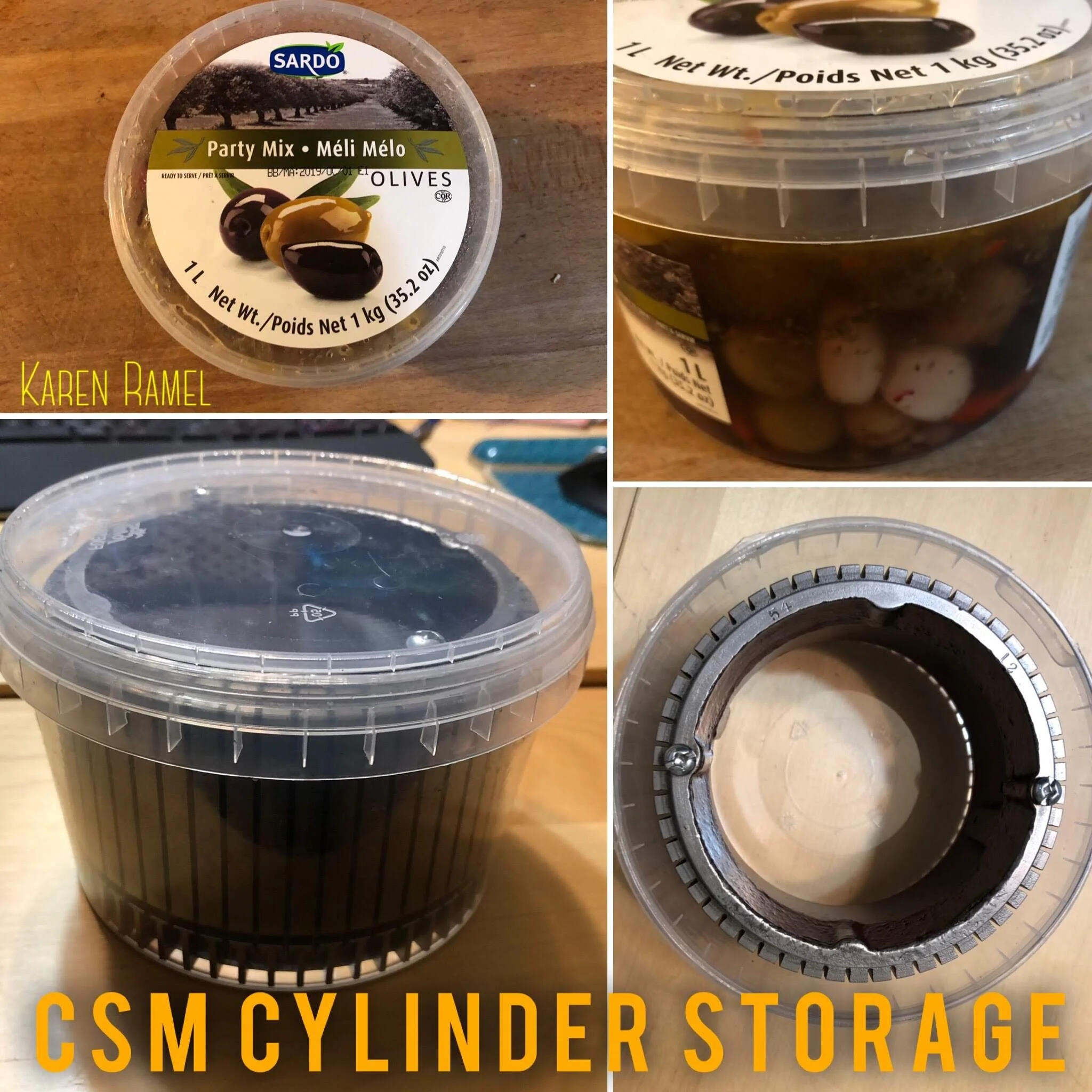

Storage

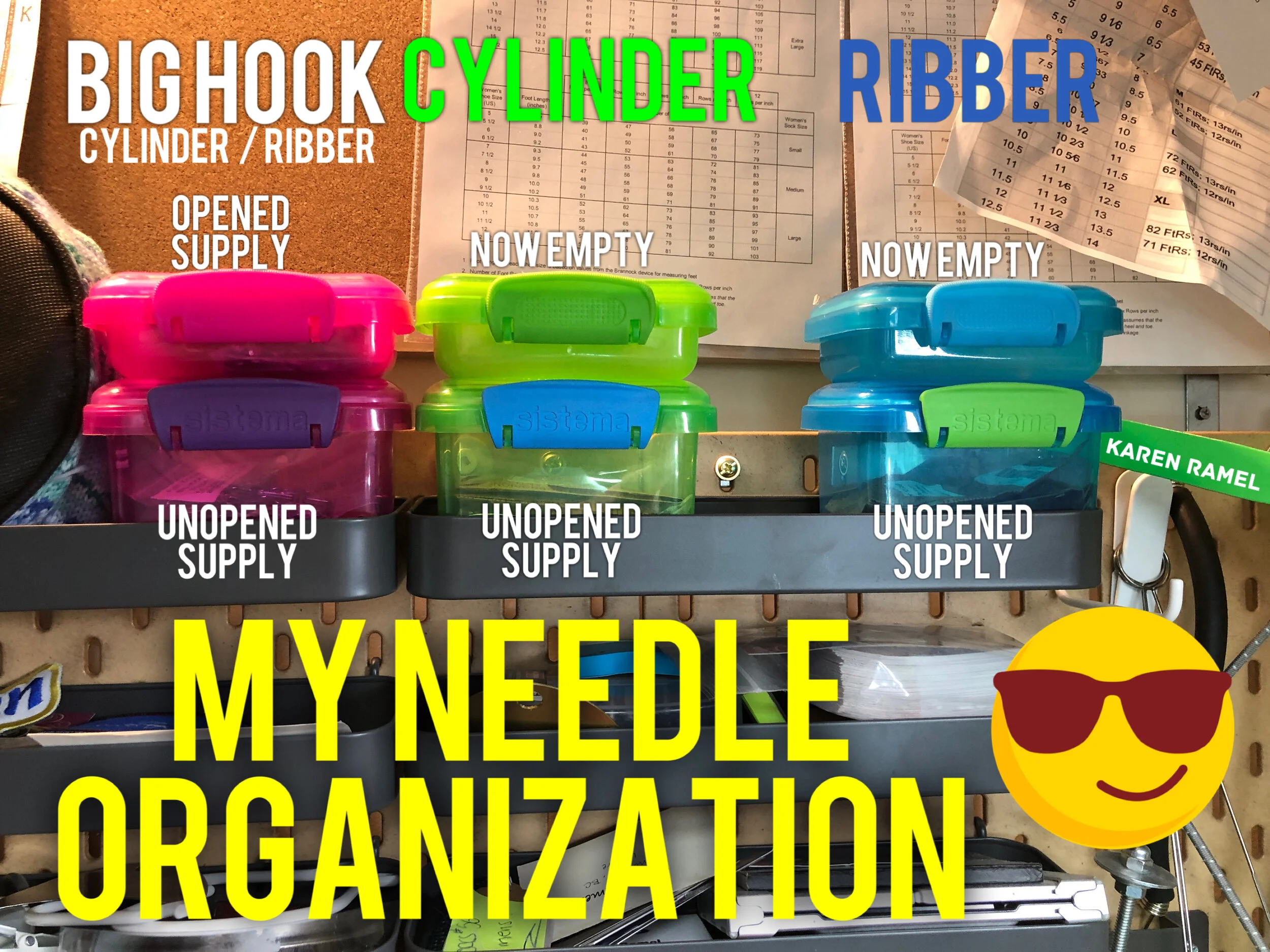

CYLINDER / RIBBER NEEDLE

Storage

Cylinder, Ribber & Stem/Weight Stacks

OTHER COVERS: Machine, Ball Chair, Floor

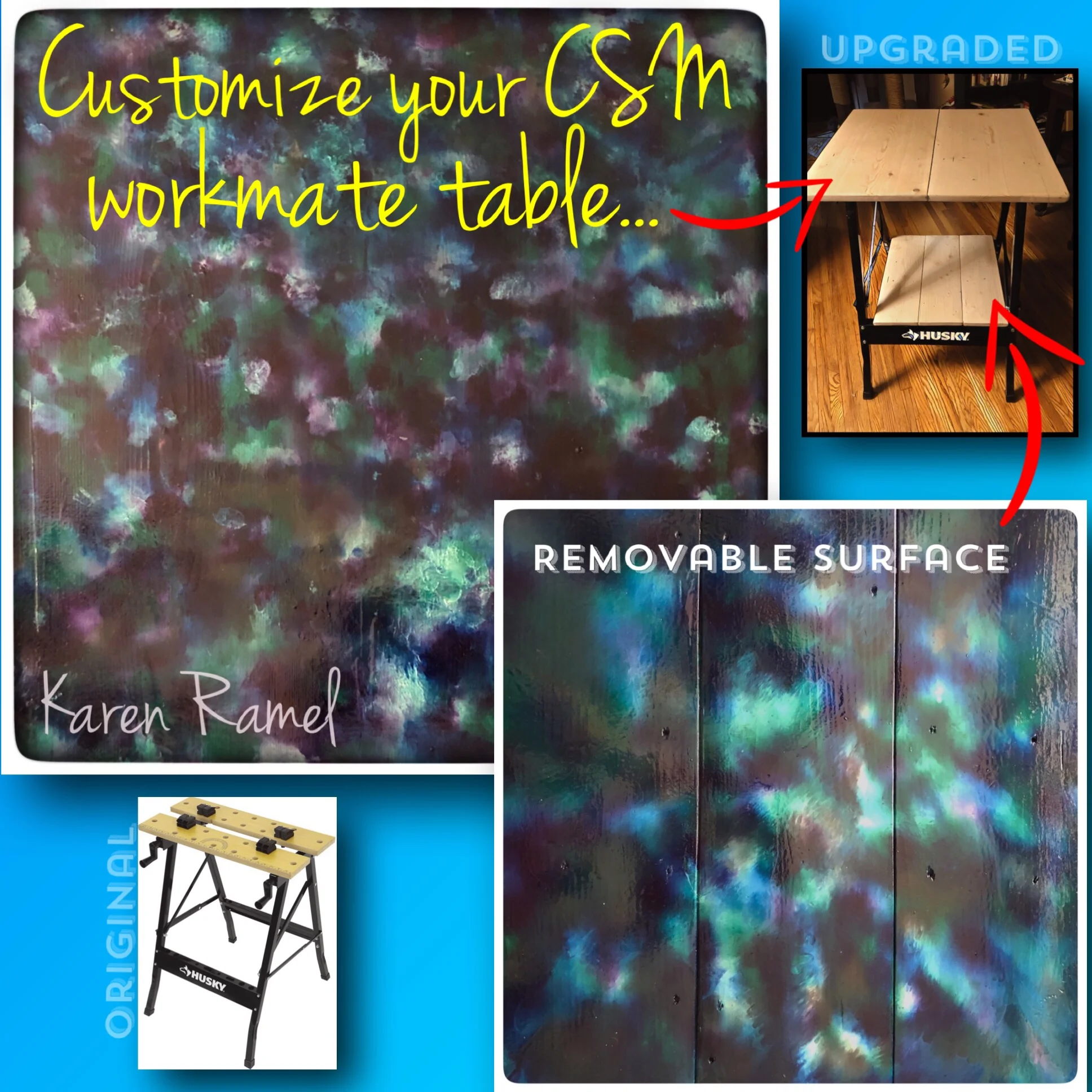

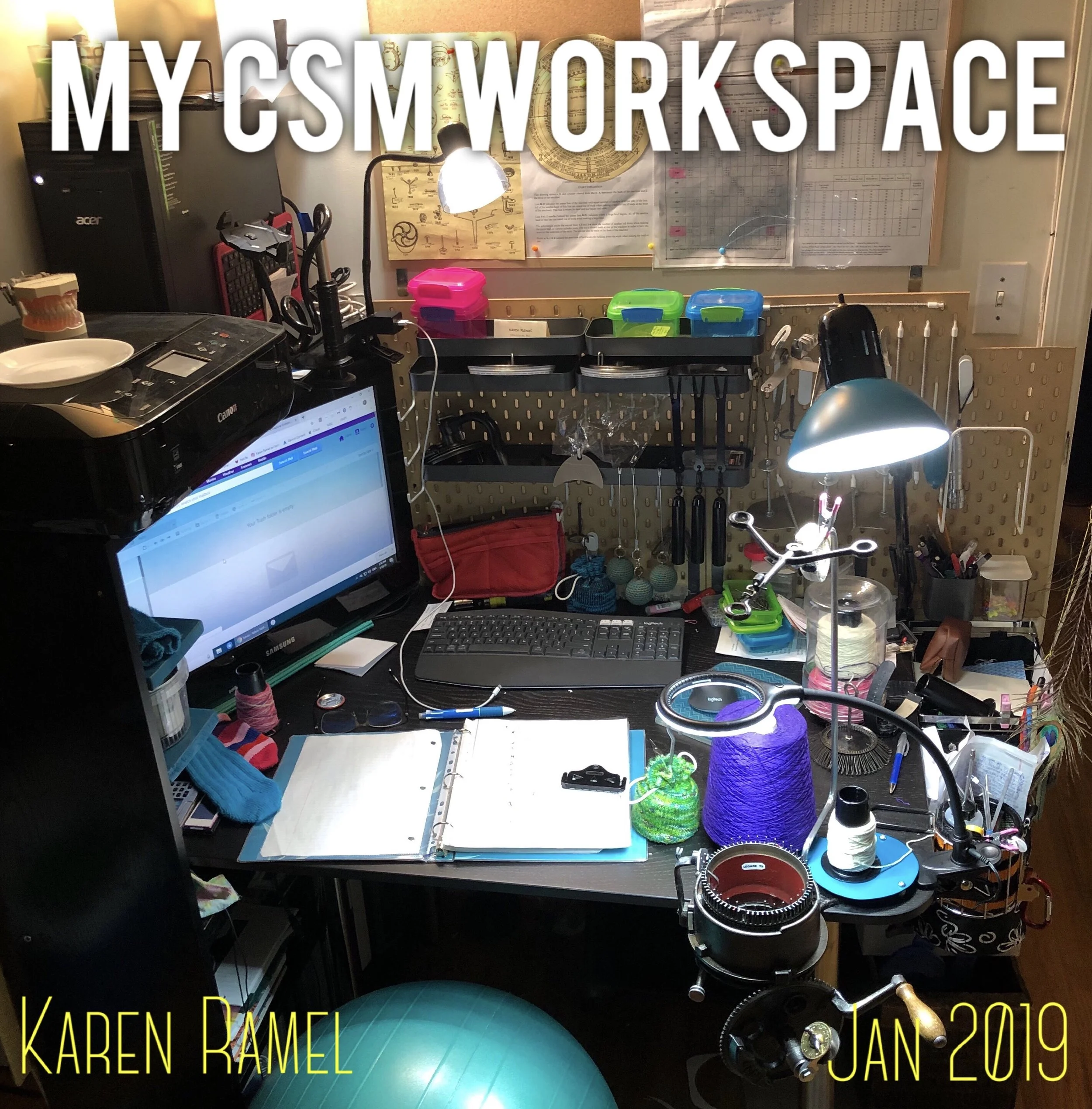

Tables and Stands

I wanted to start by saying you don’t necessarily NEED a special stand or table to use a circular sock knitting machine. If your machine doesn’t come attached to its own stand, you can certainly clamp it to any sturdy clamp-capable surface - HOWEVER as the thumbscrews or clamp screws do connect with the underside of what you clamp it to (and can damage that surface) you may want a table specifically for your machine. It makes it easier to move your machine within a room if its on its own table. That being said you don’t have to spend a lot to find something that works for you, some people simply use a bar stool - whatever you use - just ensure its sturdy and won’t easily tip over.

See the images below (click to make bigger) for ideas and/or go to my quick lookup page INDEX and find the TABLE category to view tables by their brand. This INDEX page can be found on my homepage under the MISC MENU.

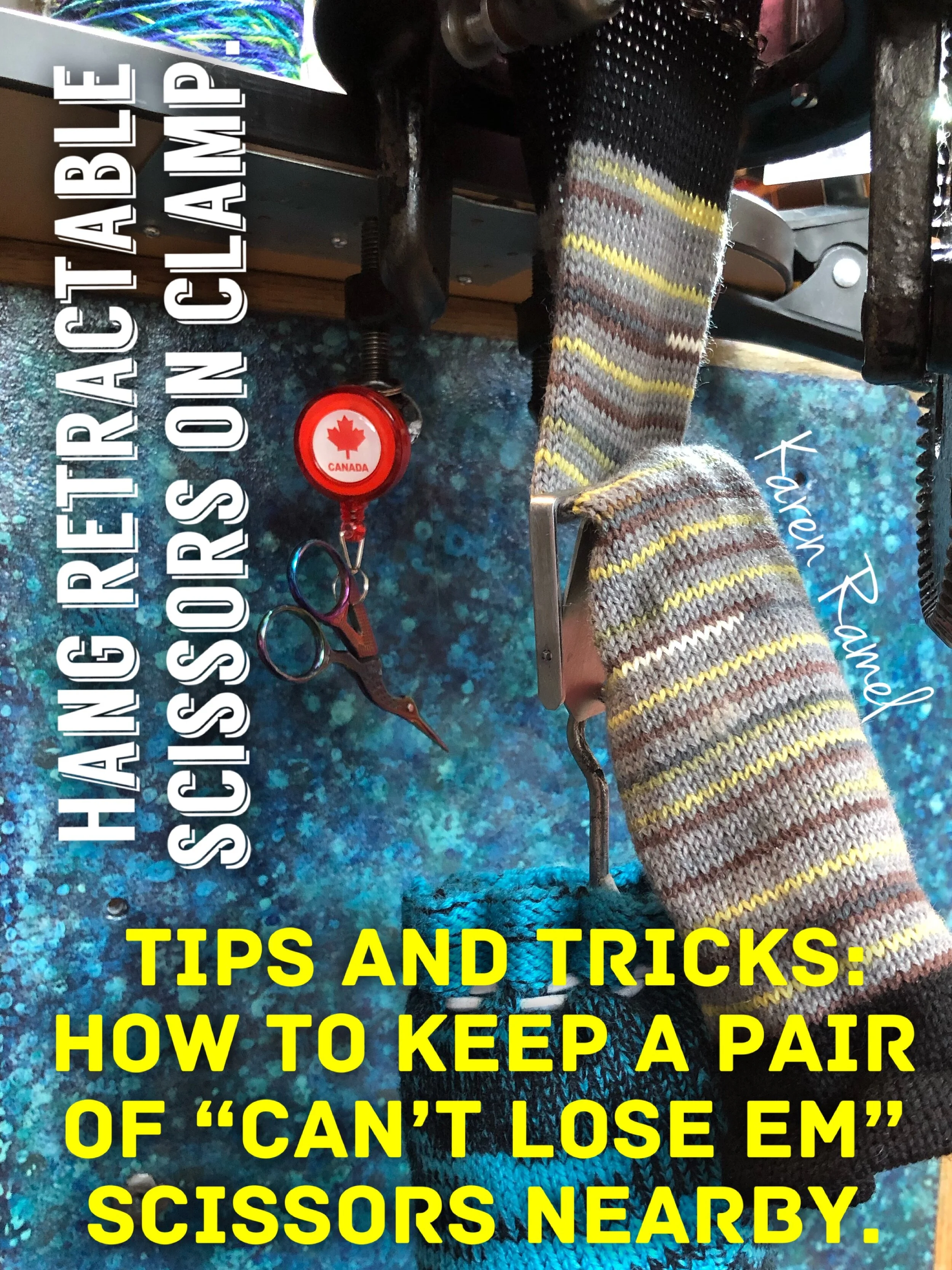

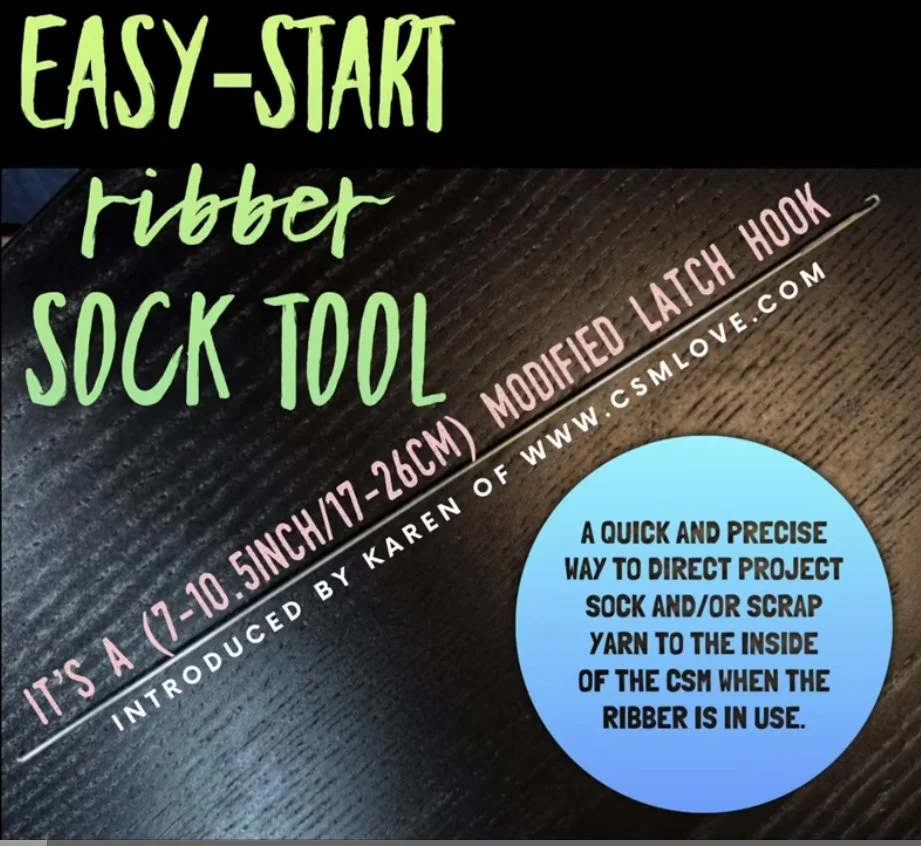

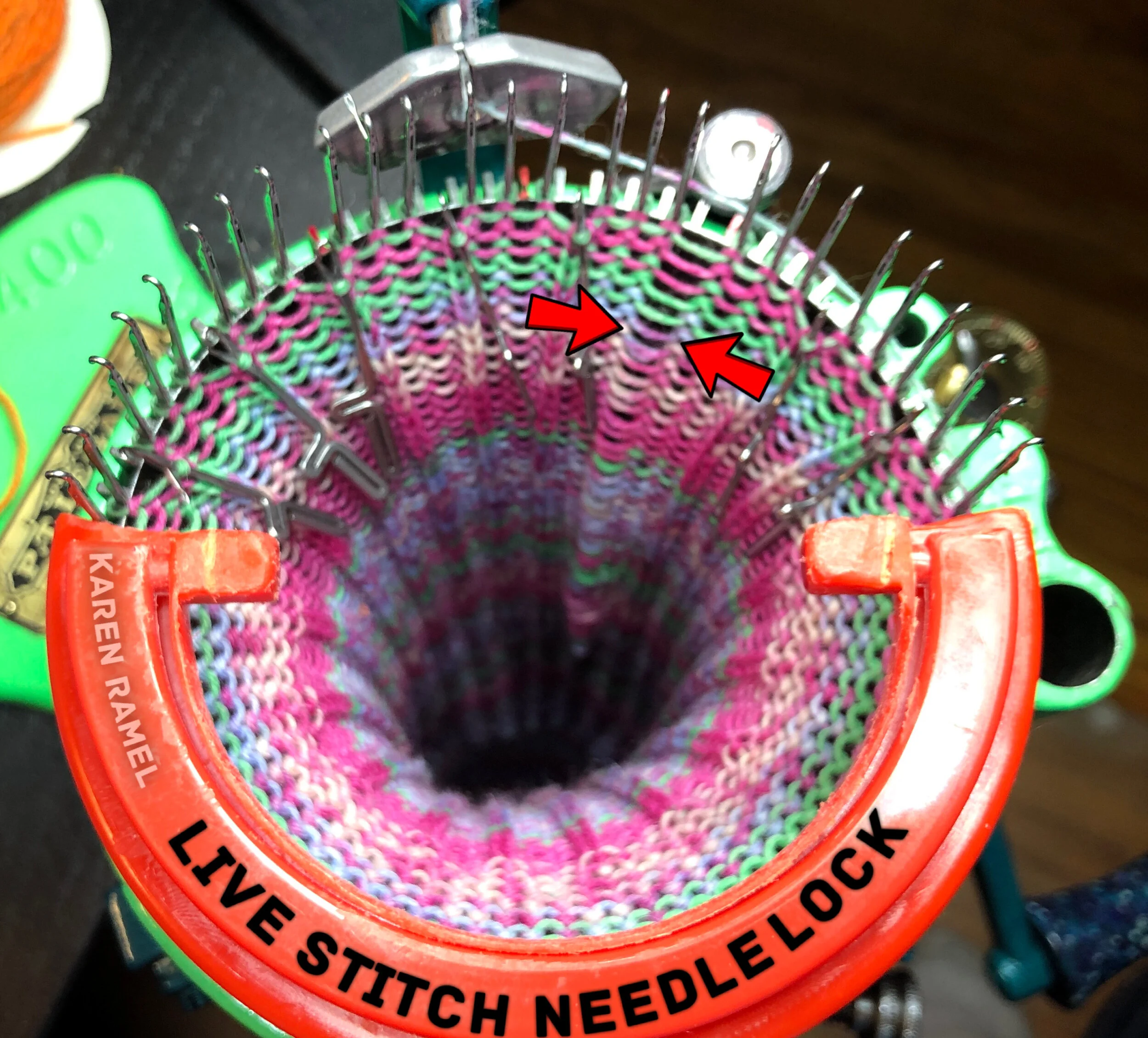

TOOLS AND TOOL MODIFICATIONS

Tools Created To Make Things EASIER

Read more about the four pictures here on my April 11, 2021 Blog Post. While using elastics on the CSM to trap stitches so that they don’t come undone when working on a stitch fix, this new Lilve Stitch Needle Lock item is my design and an upgrade as this simple item prevents your knitted work from getting snagged on the cylinder needles.

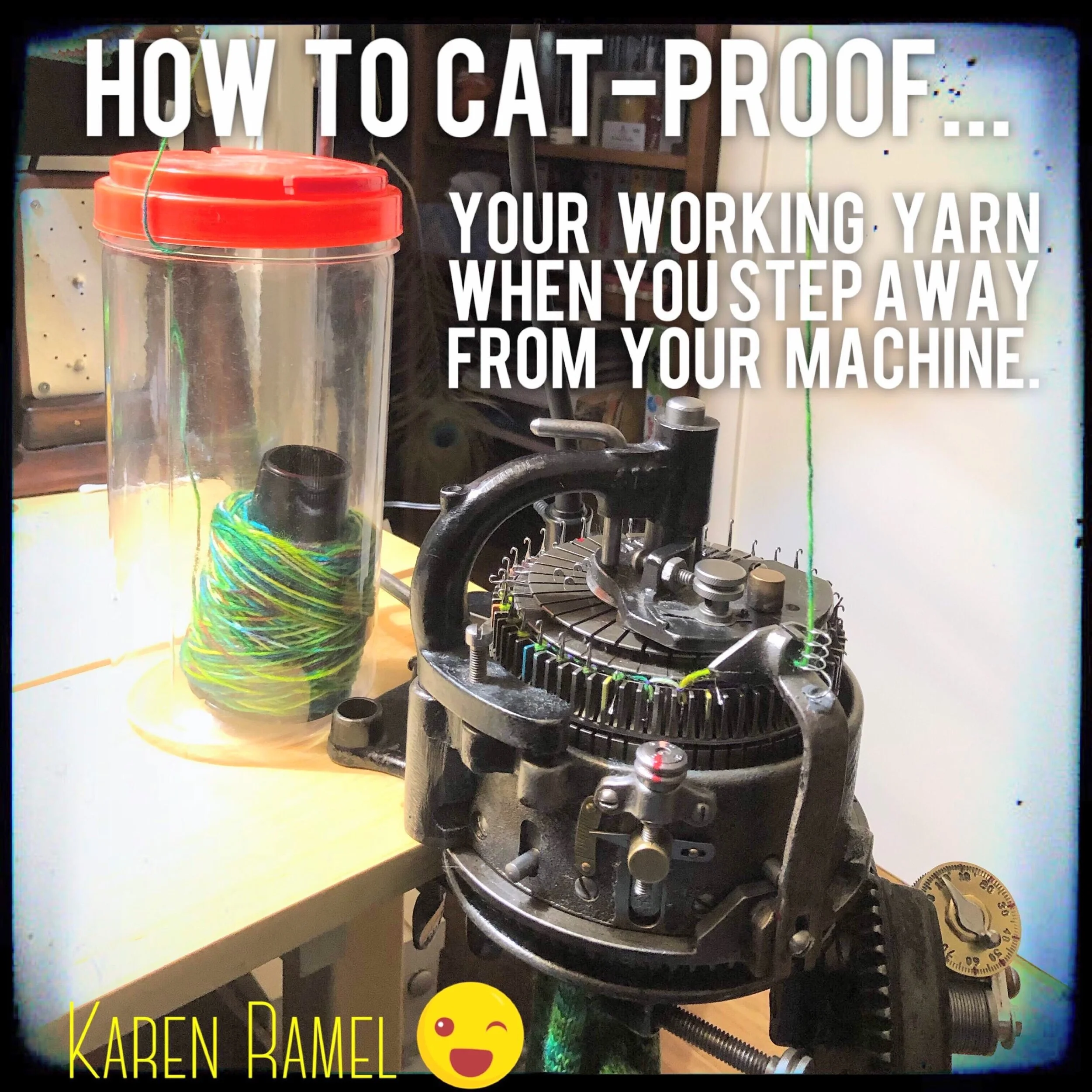

You might recognize the red lid from the Dec 2018 share photo on cat proofing yarn posted above in the “Tips, tricks and things to note” segment. This red lid might have been from a cashew nut container.

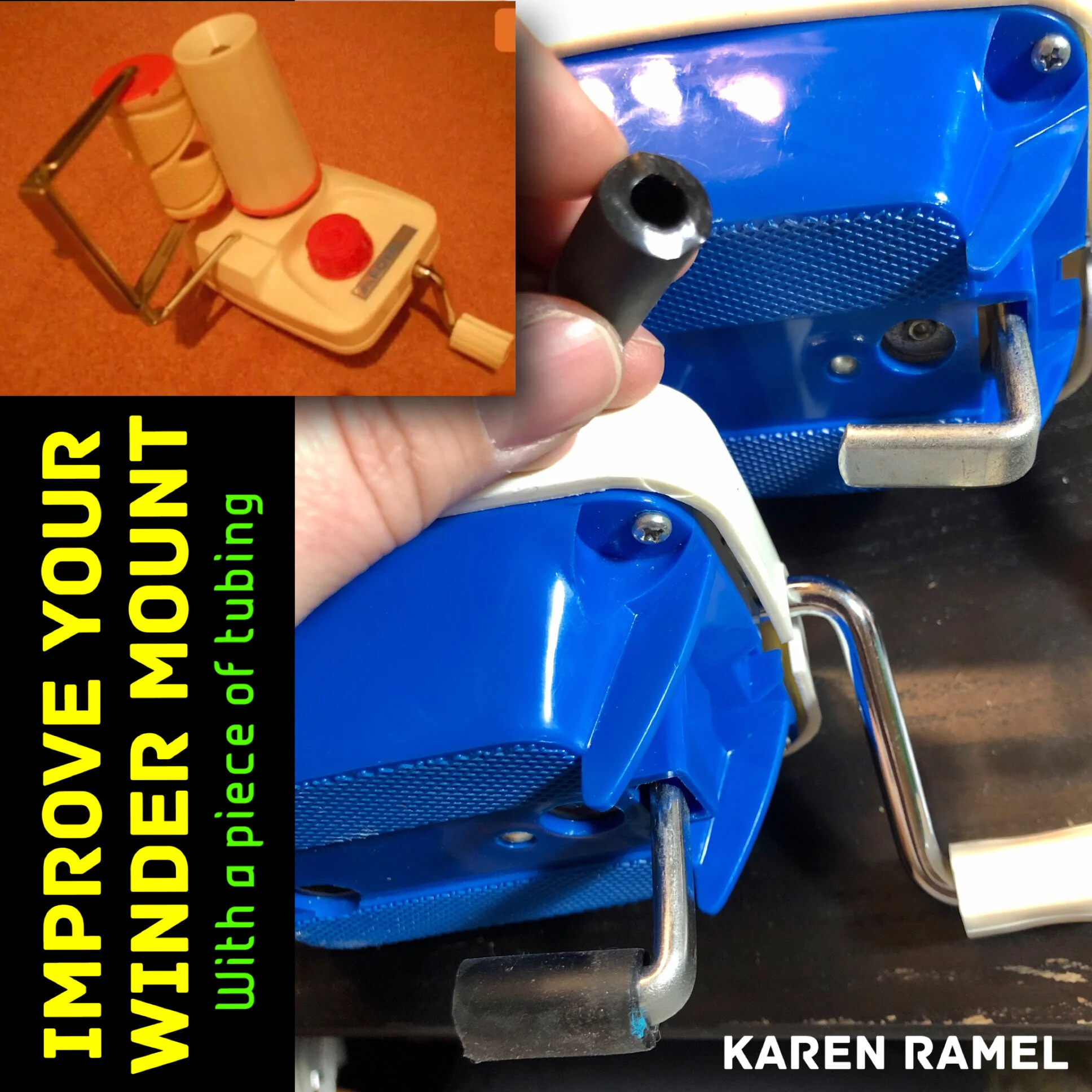

Yarn Winder Related

I’ve created an electric Royal Cone Winder for my own use. Check it out :) Version 2 in the works. Shareable video: https://youtu.be/Mr4pB6f3sBE

Tips, Tricks and Things to note…

TIPS and TRICKS

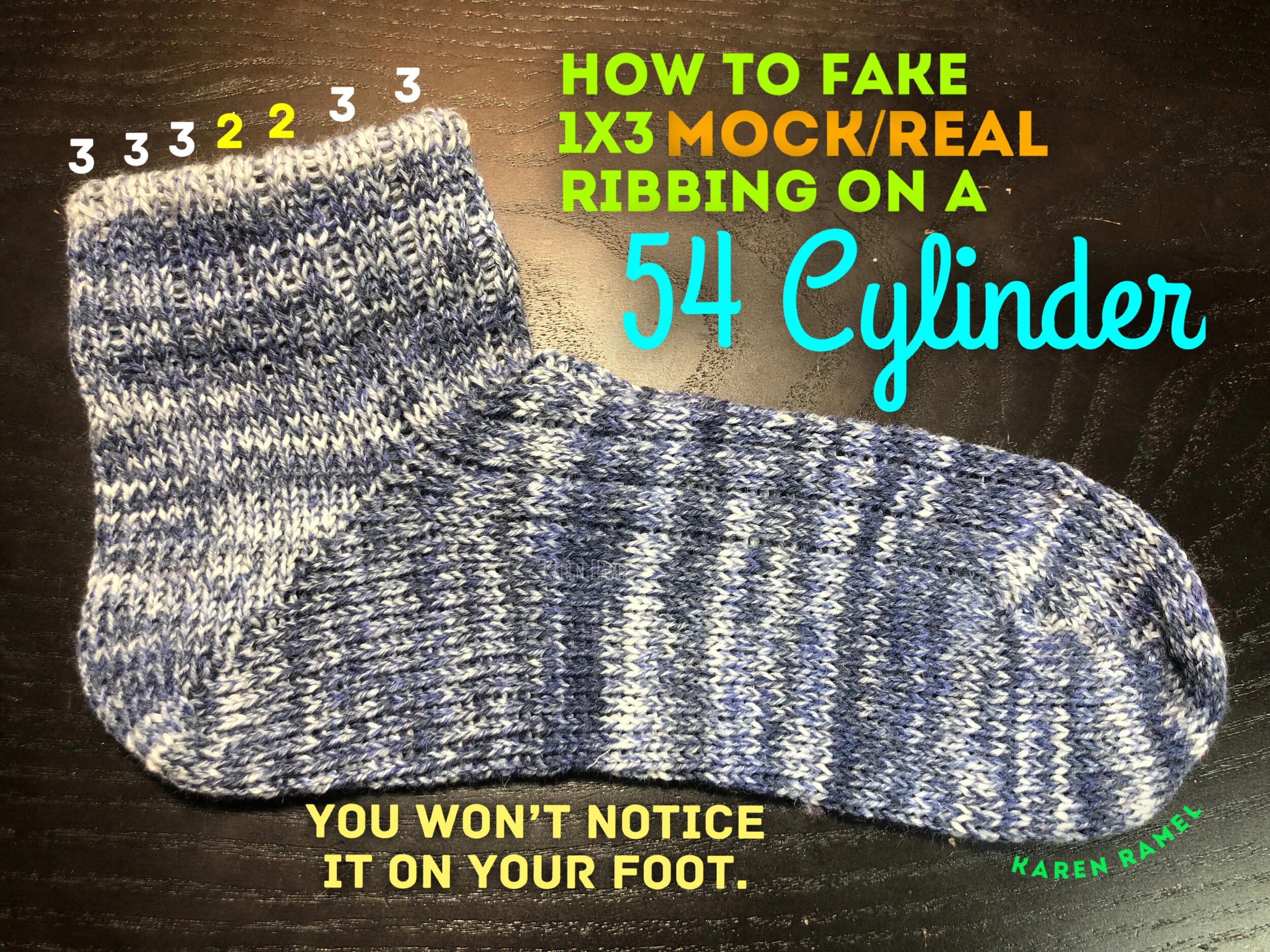

RIBBING PATTERNS ON ANY CYLINDER

When deciding to work a certain ribbing (or mock rib) pattern on your cylinder you can look to see what the MATHEMATICAL breakdown on which ribbing patterns will work - OR - you can wing (or fudge) it. See below.

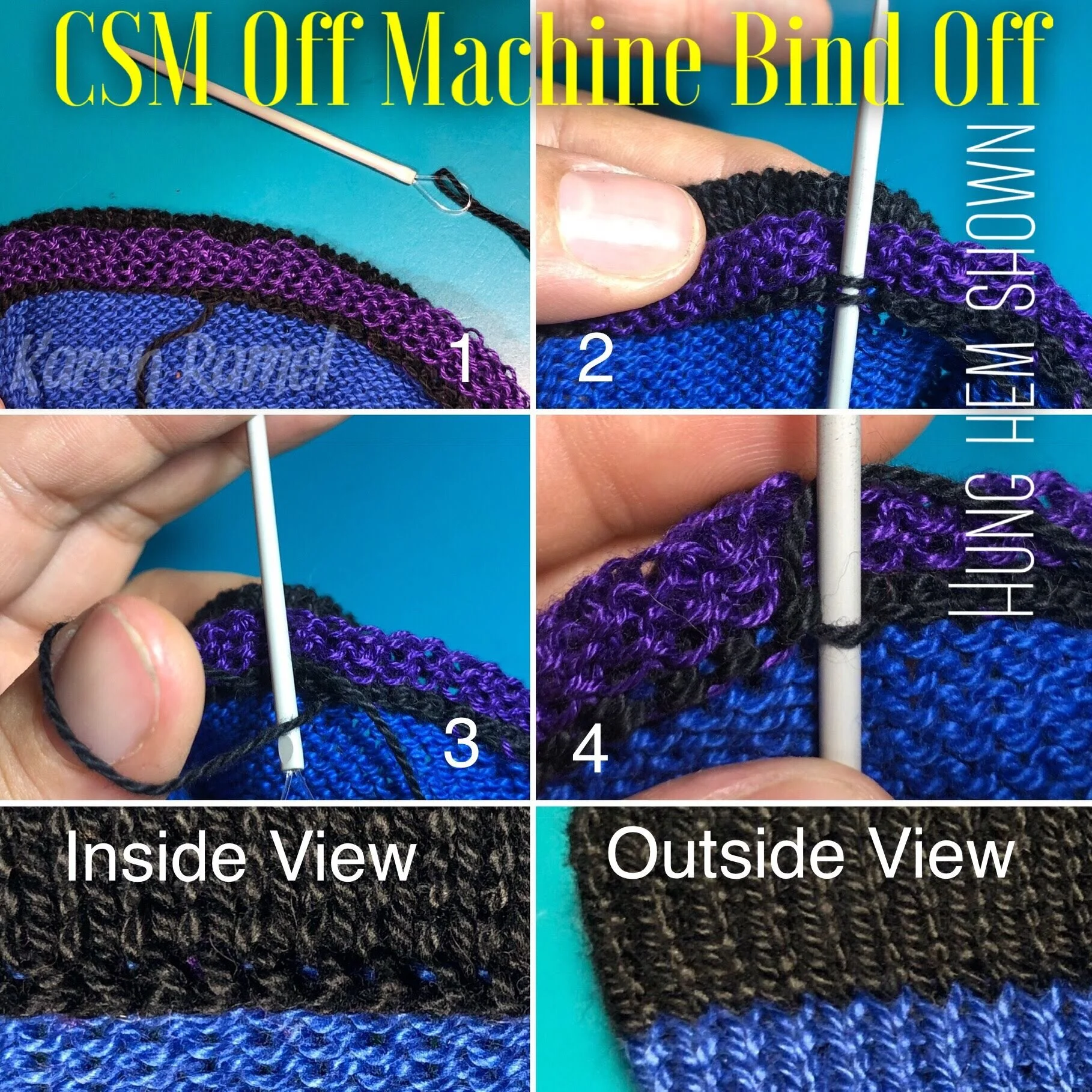

TECHNIQUE - CAST/BIND OFF, Stitch Technique

For videos see this page

Technique

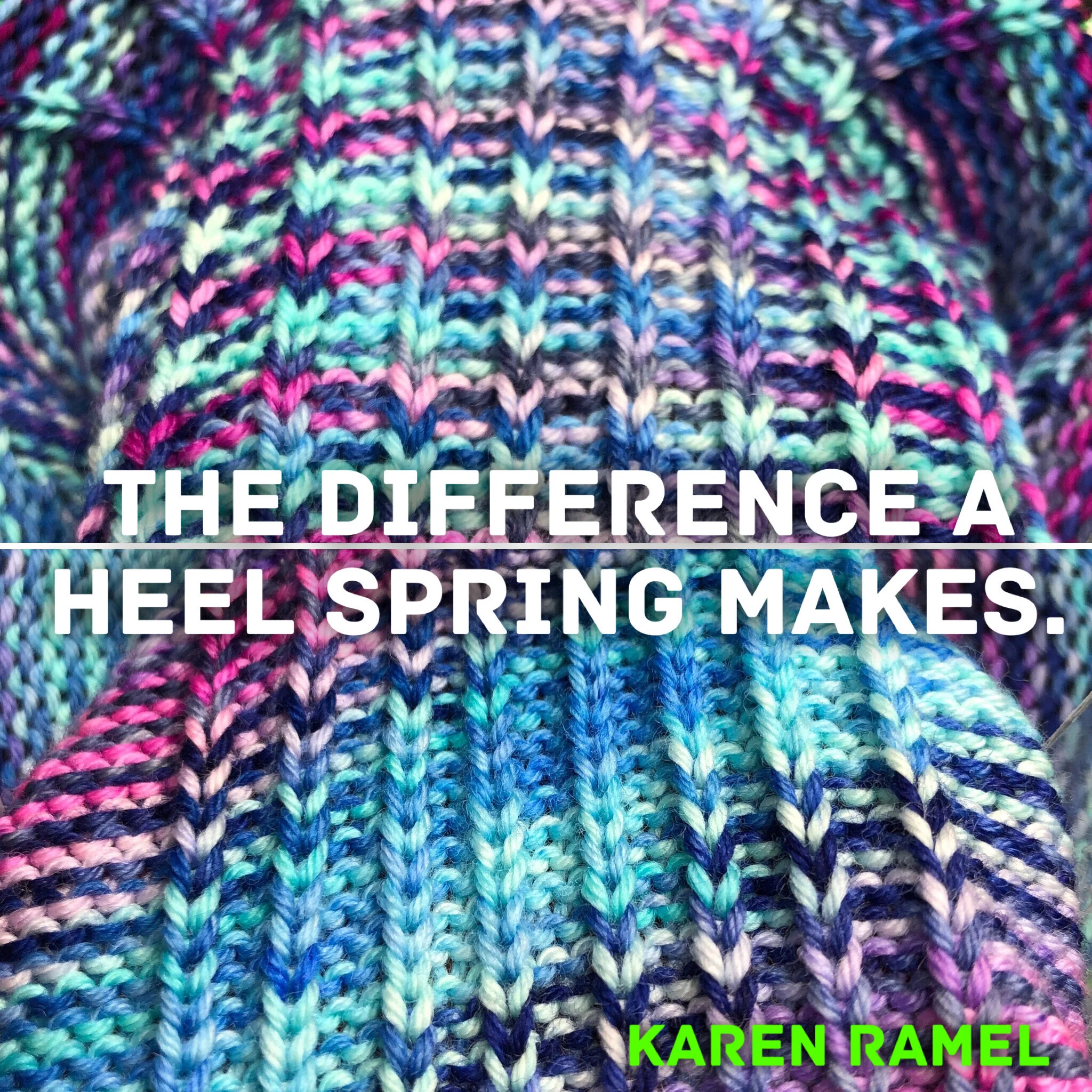

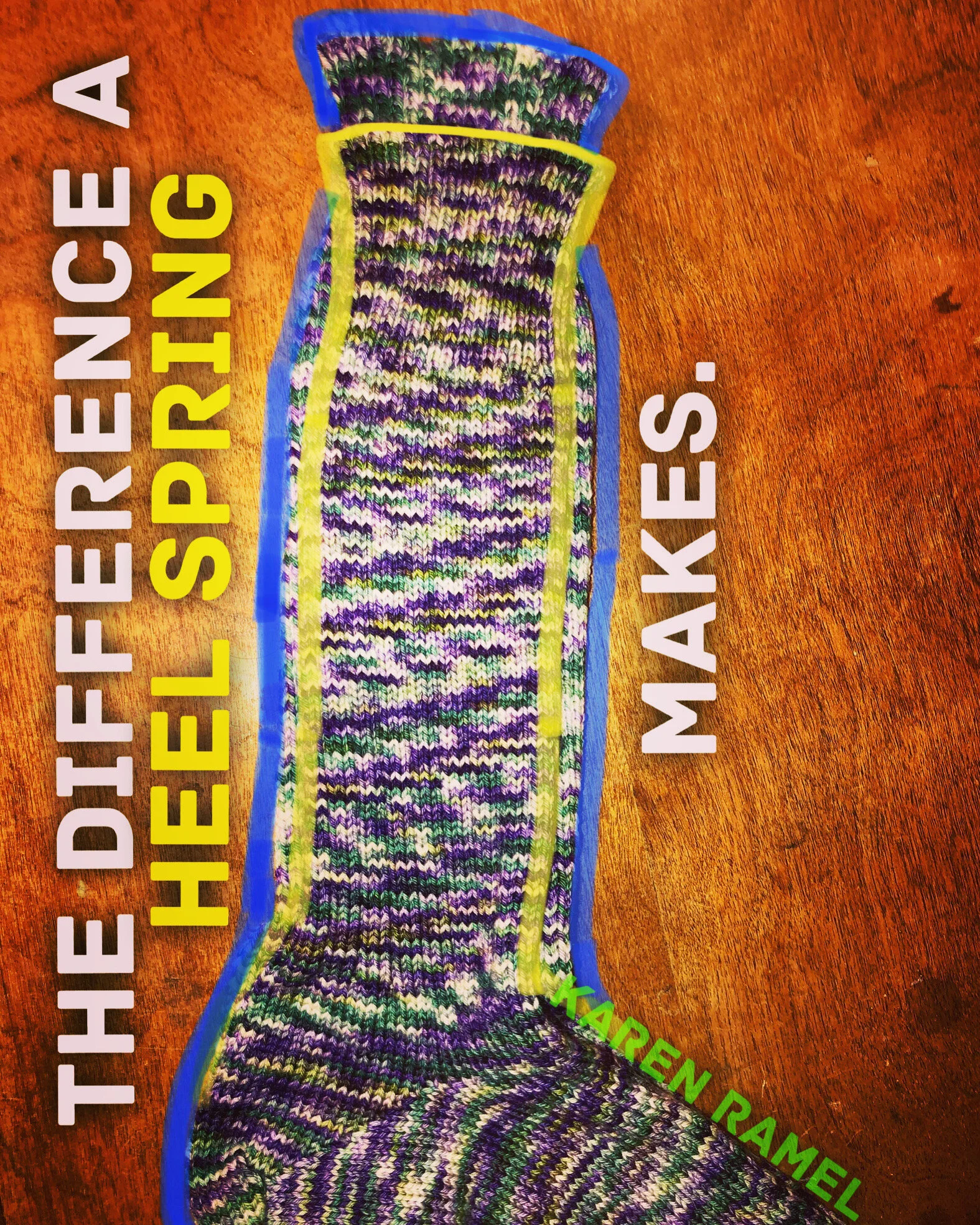

Heel Spring exploration

For info on the this section please see the CSM Start-CSM3 page.

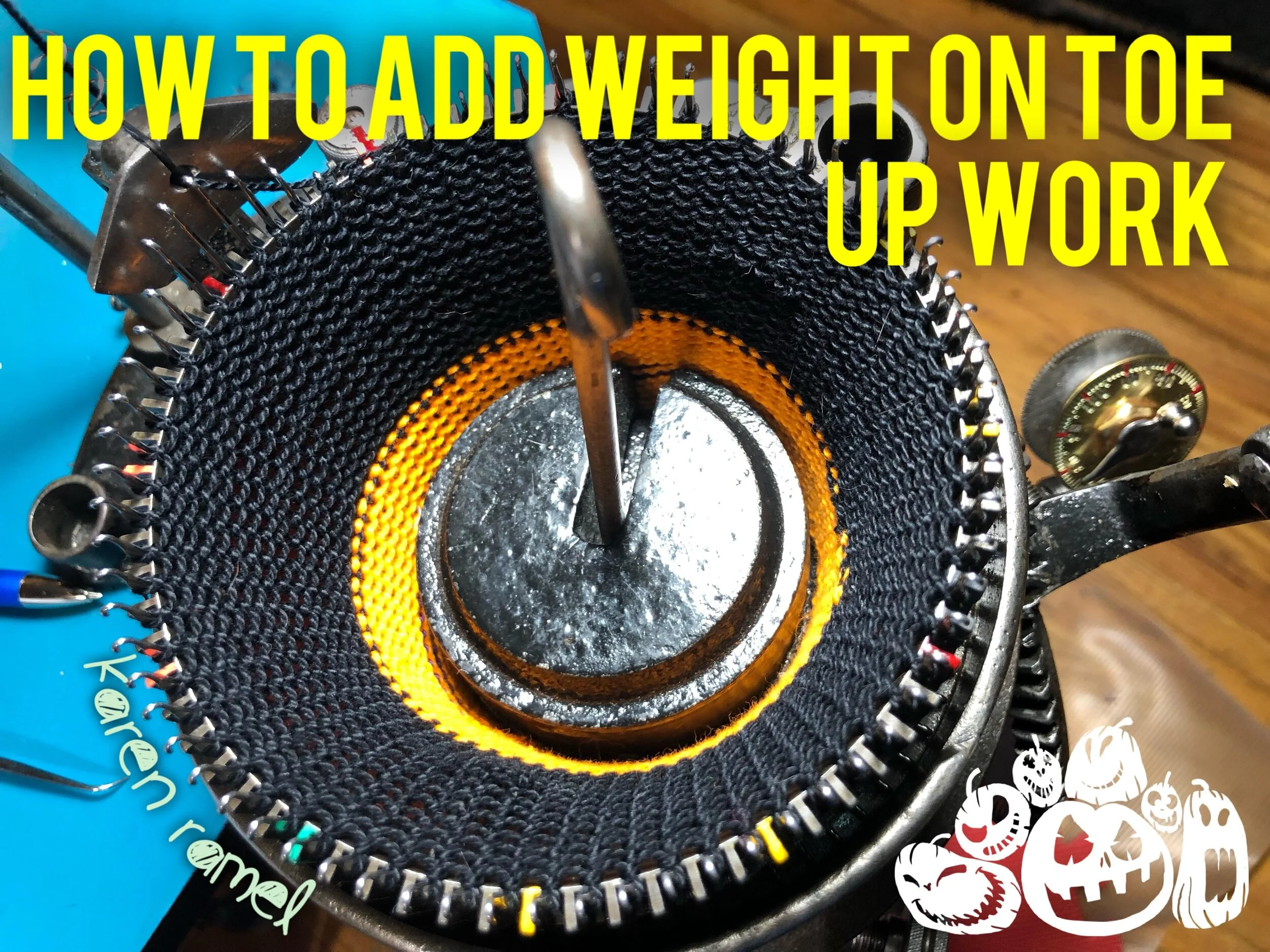

Weights

See this blog entry for more info on weights used on the circular sock machine and your options.

Interested in clear footwear to show off your socks? See these Jeffrey Campbell Heeled Rain Boot

Seeking a specific topic? You can additionally see the INDEX page under that category

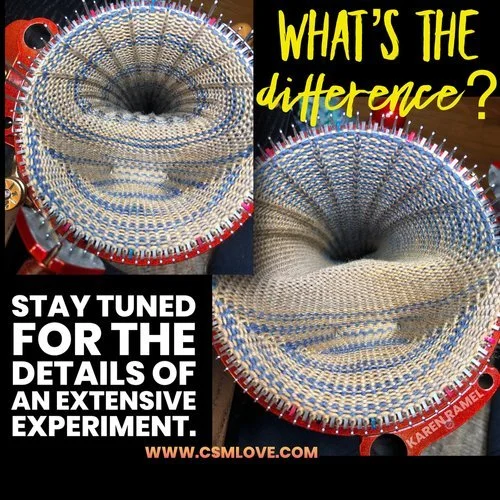

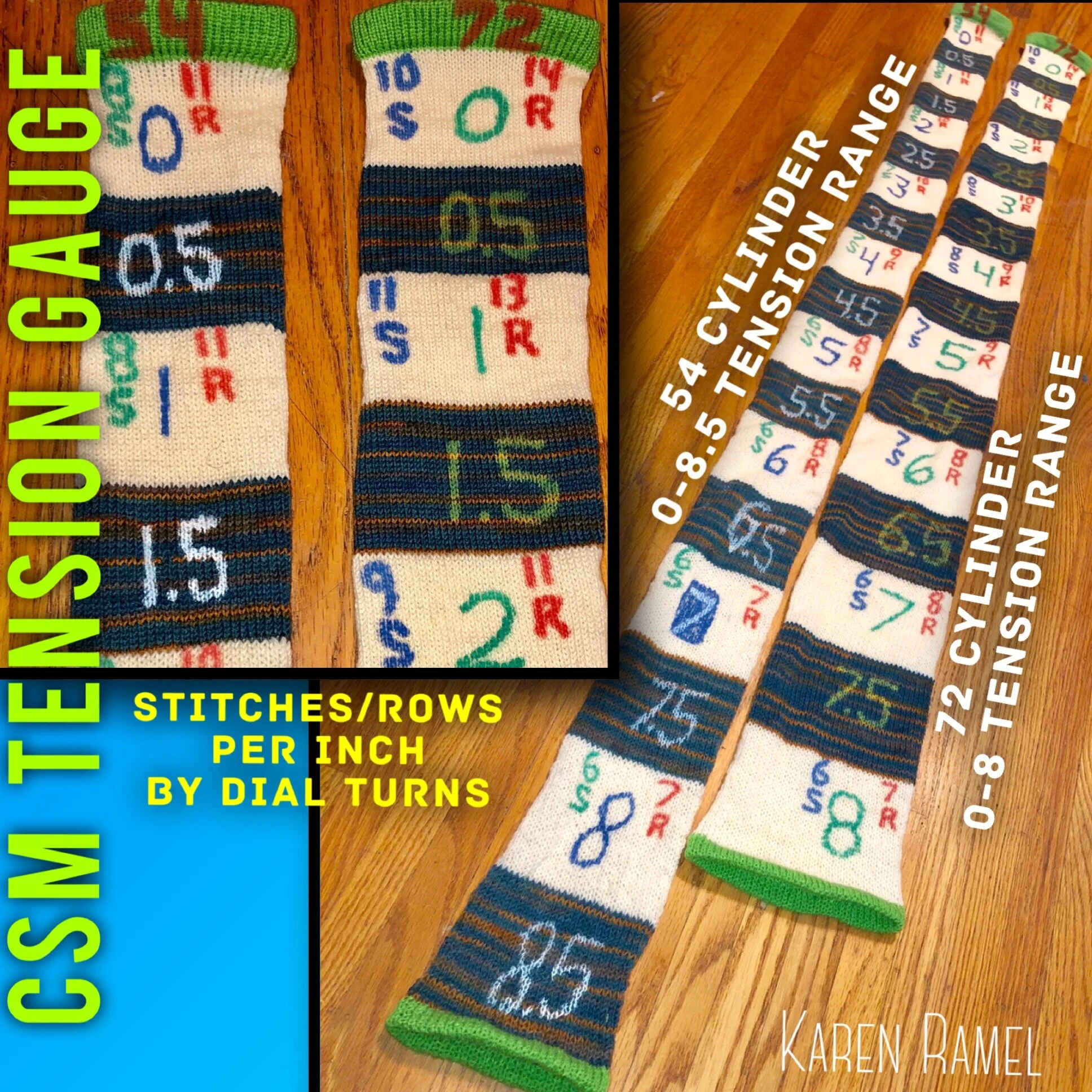

Extensive Tension Dial relation to sizing experiment resulted in a size bigger sock for each half turn of the dial! See the details on this blog entry. https://www.csmlove.com/blog/2021-oct-16-the-difference-the-tension-dial-setting-makes