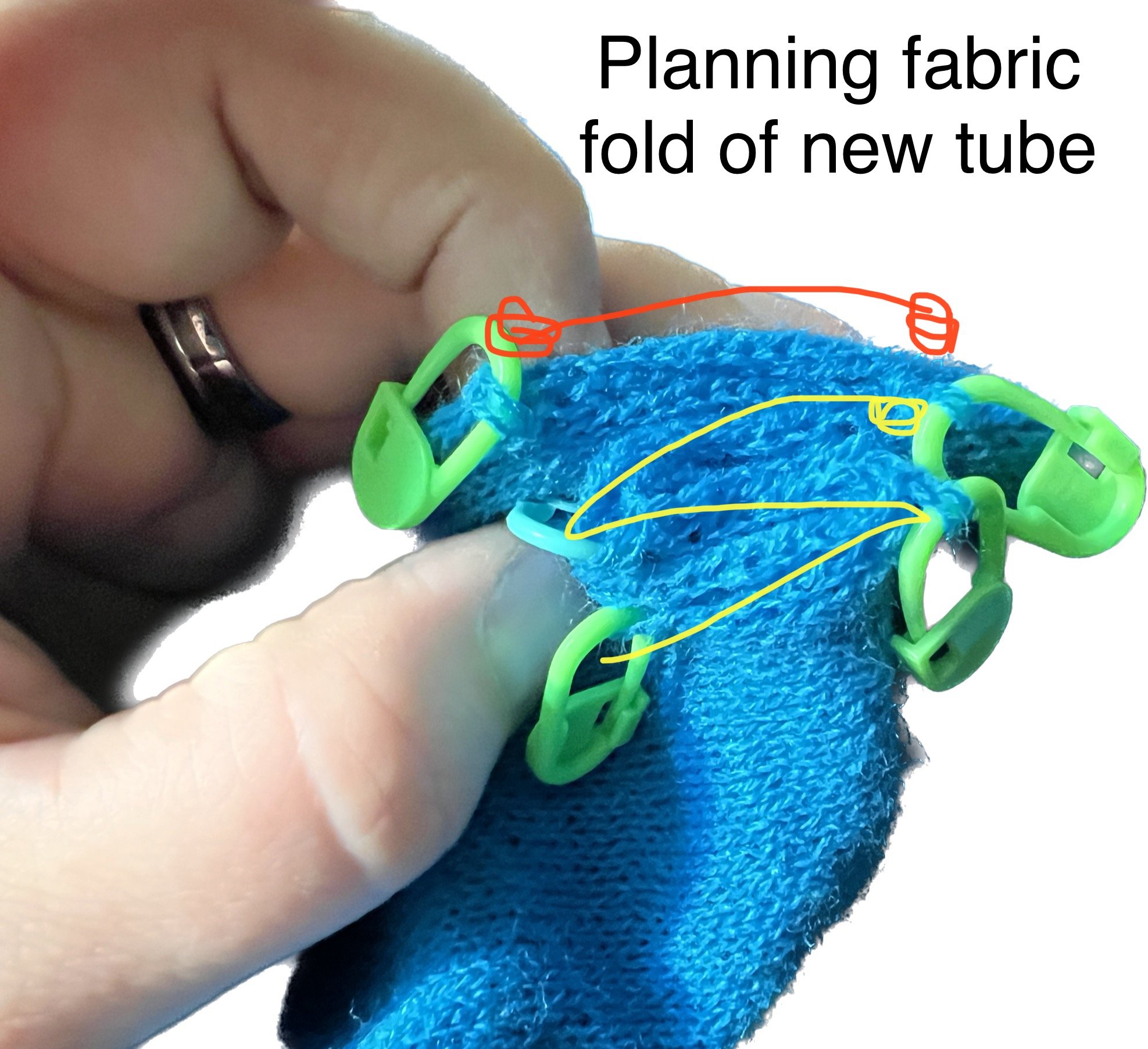

(Addi-Express Kingsize Table)

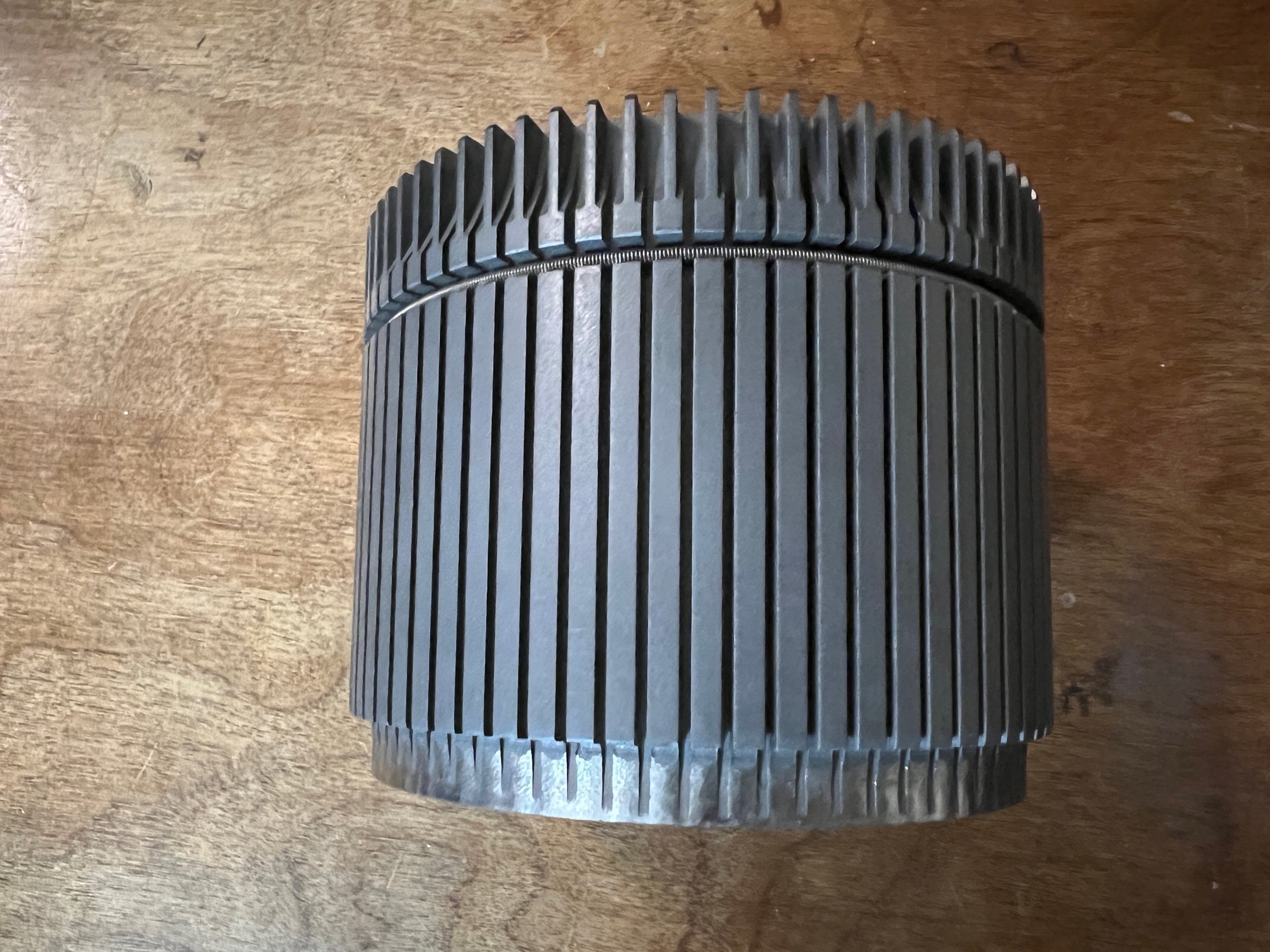

Many years ago I had this plastic 44 needle knitting machine, at the time I created a custom table to make using it much easier. I’m remaking that table today.

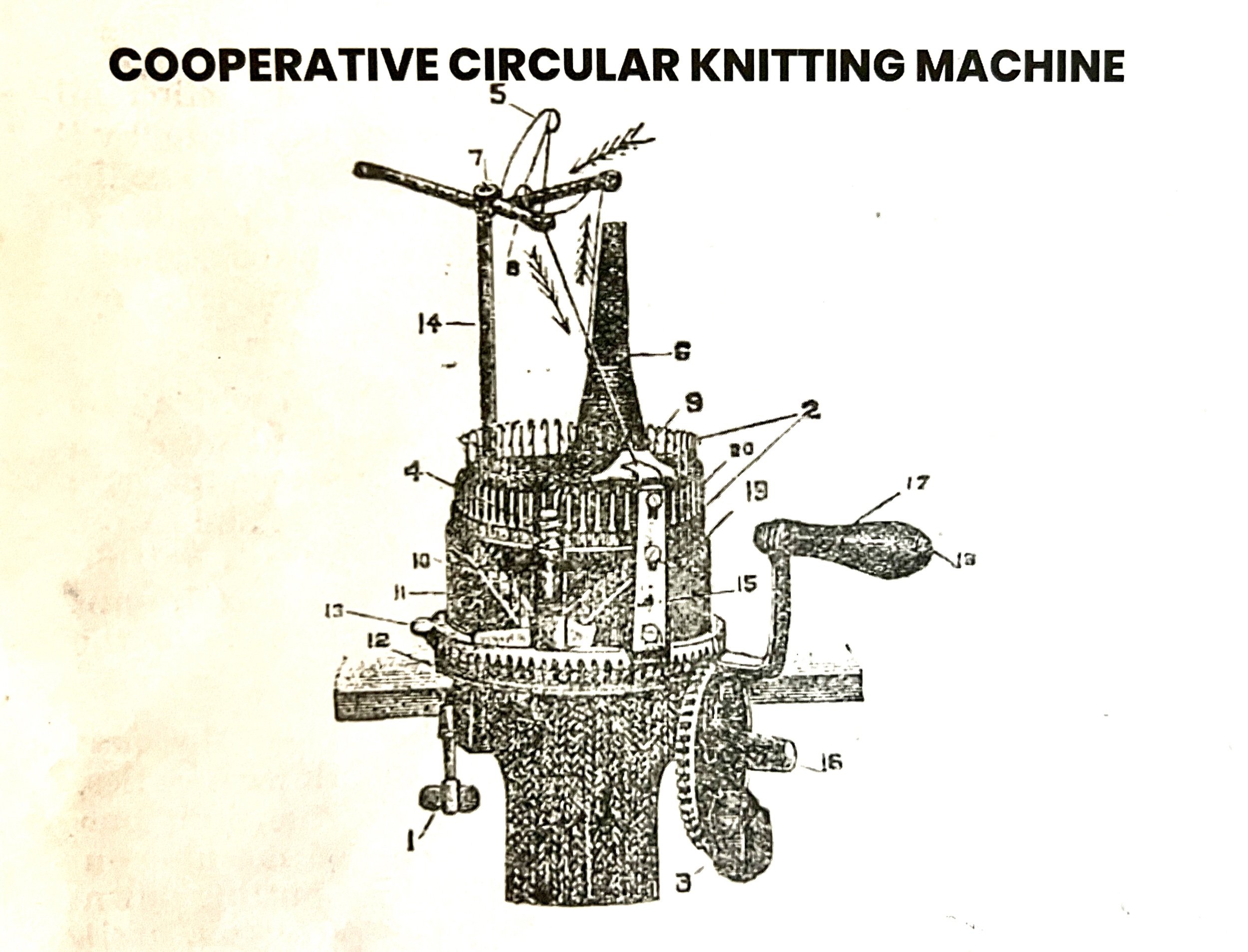

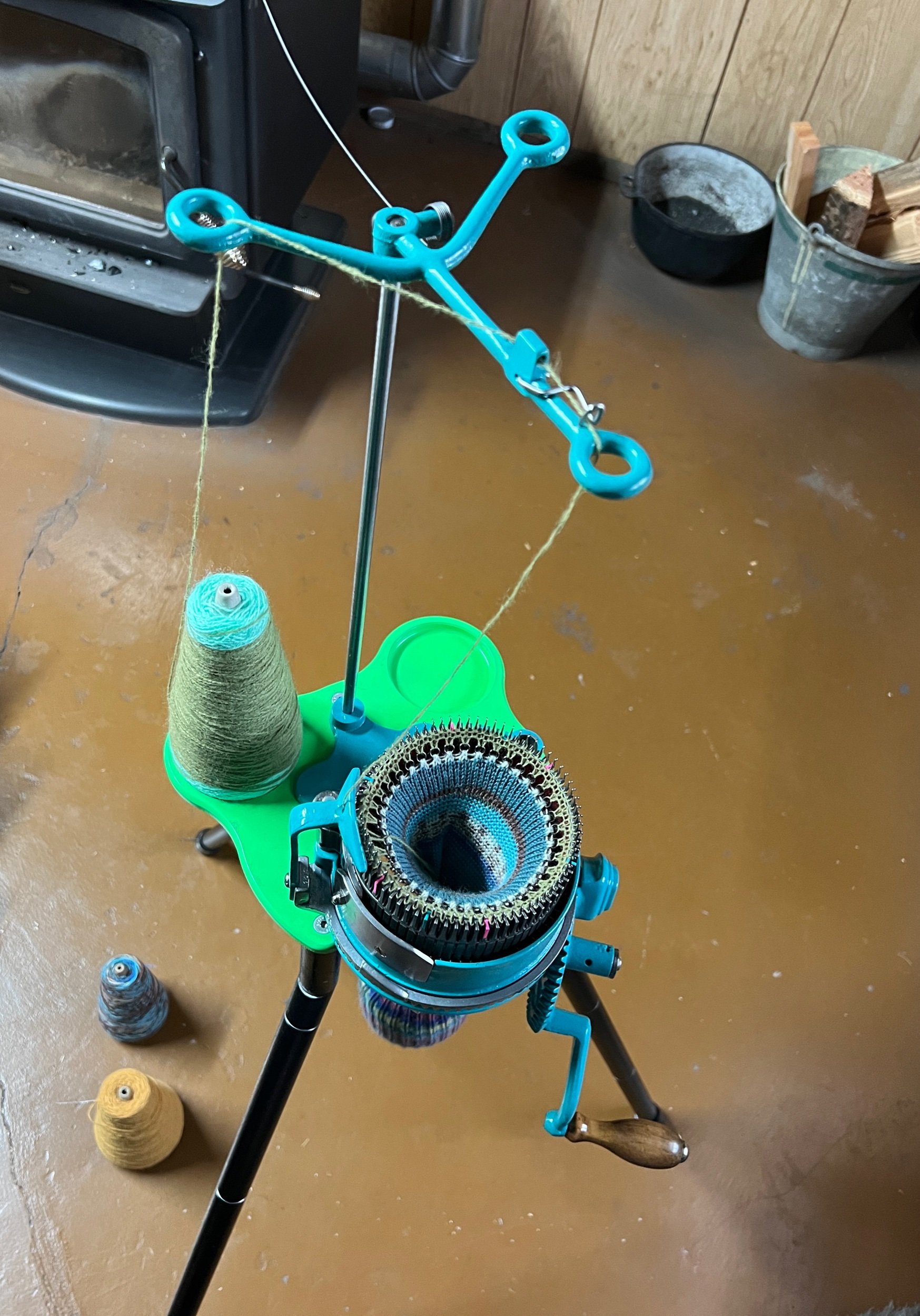

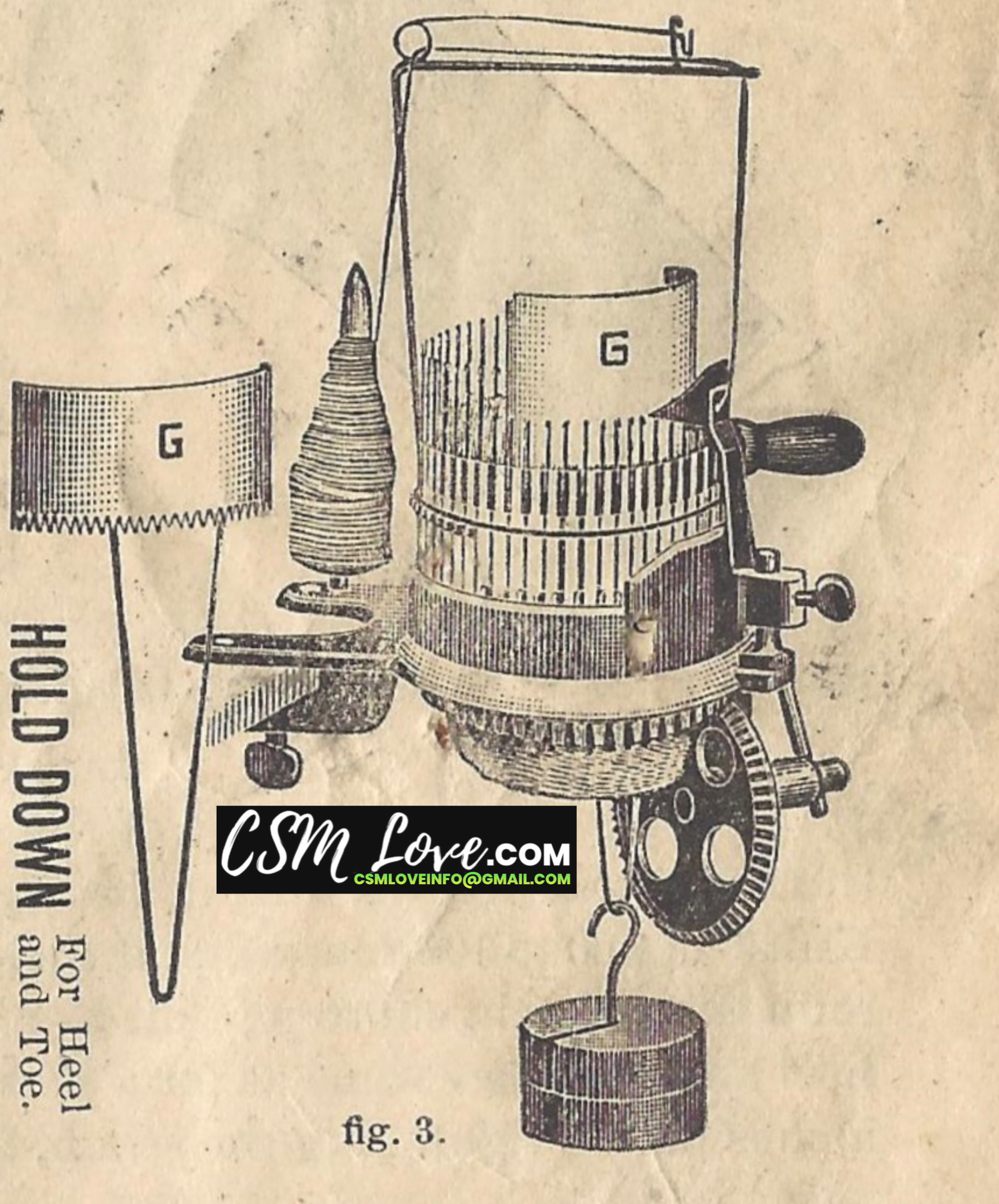

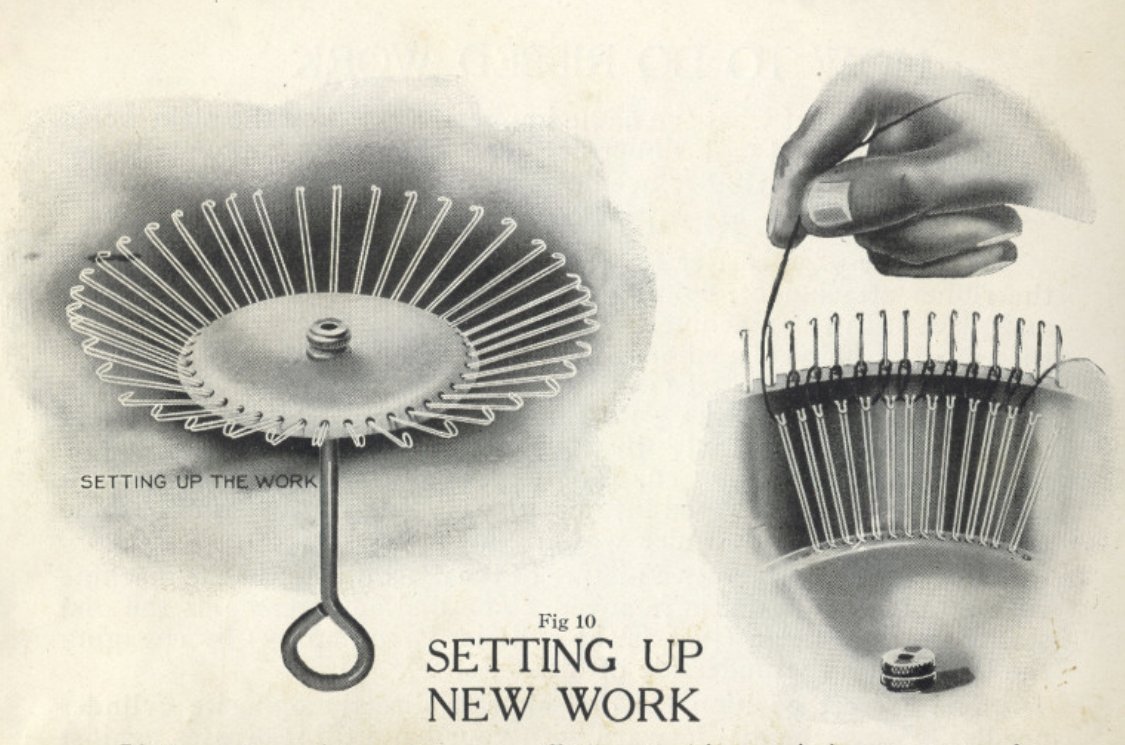

Having the easy space under the machine for the project to hang reduces twisting however more importantly being able to do so creates reliable stitches produced at an ideal working height - work doesn't get bunched up - like how machines like circular sock machines function.

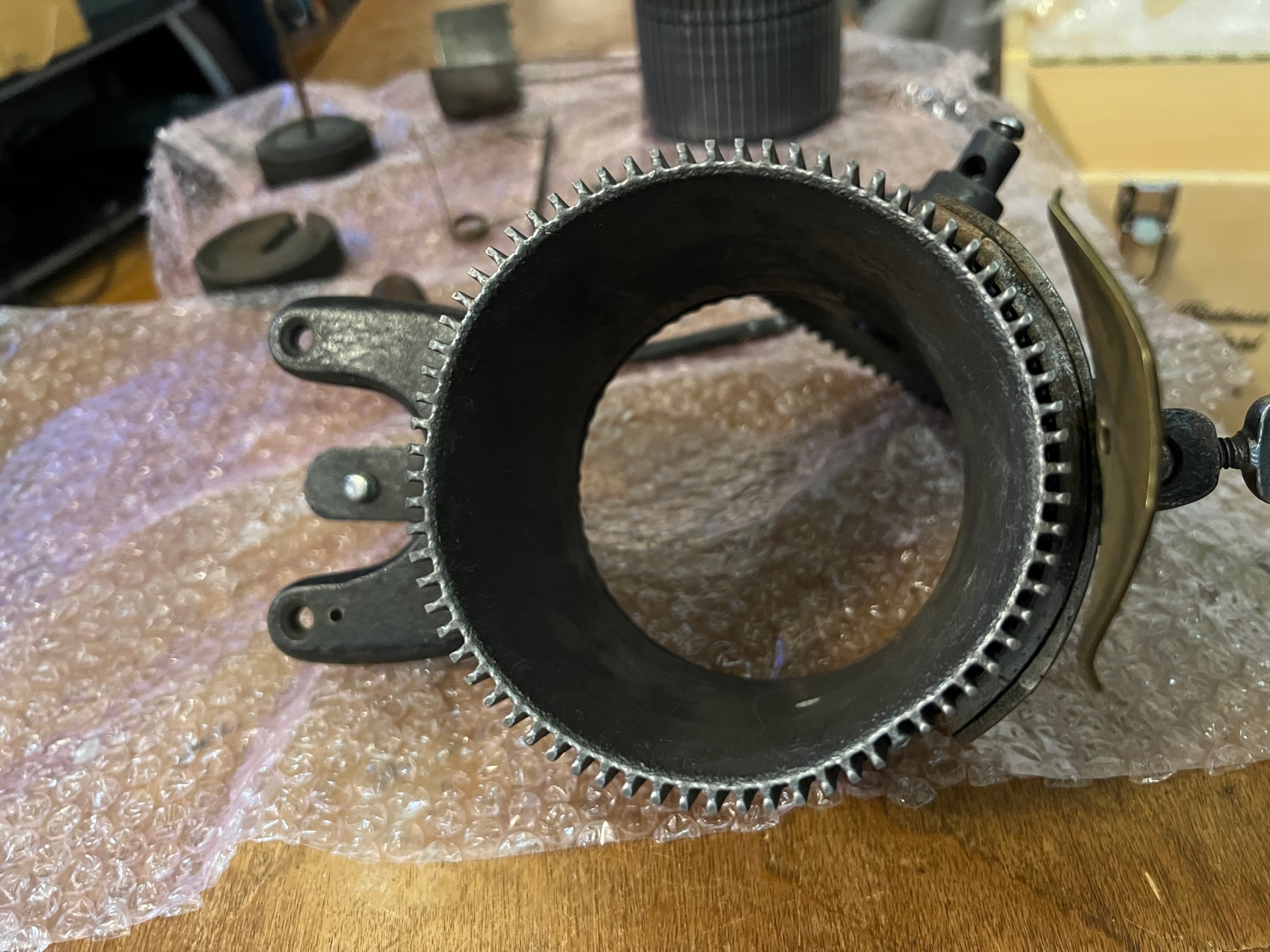

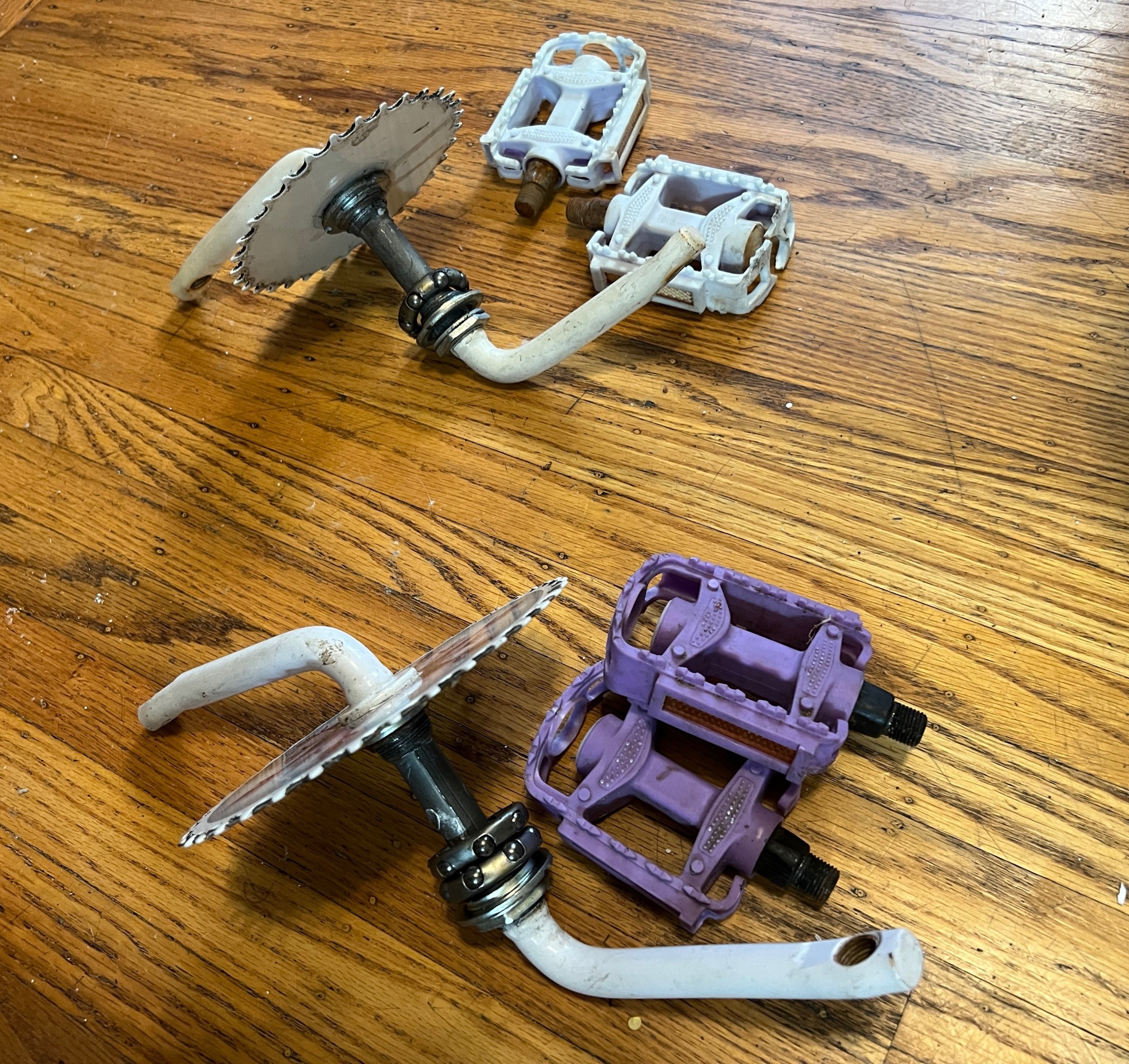

First we went to Canadian Tire (hardware store) and picked up this wooden table for $20. Tonight I reconfigured the support bracket - moving it from the middle underside of the table to the edge. The bracket has two wood supports and a bar that provide a basic slide for storage and setup.

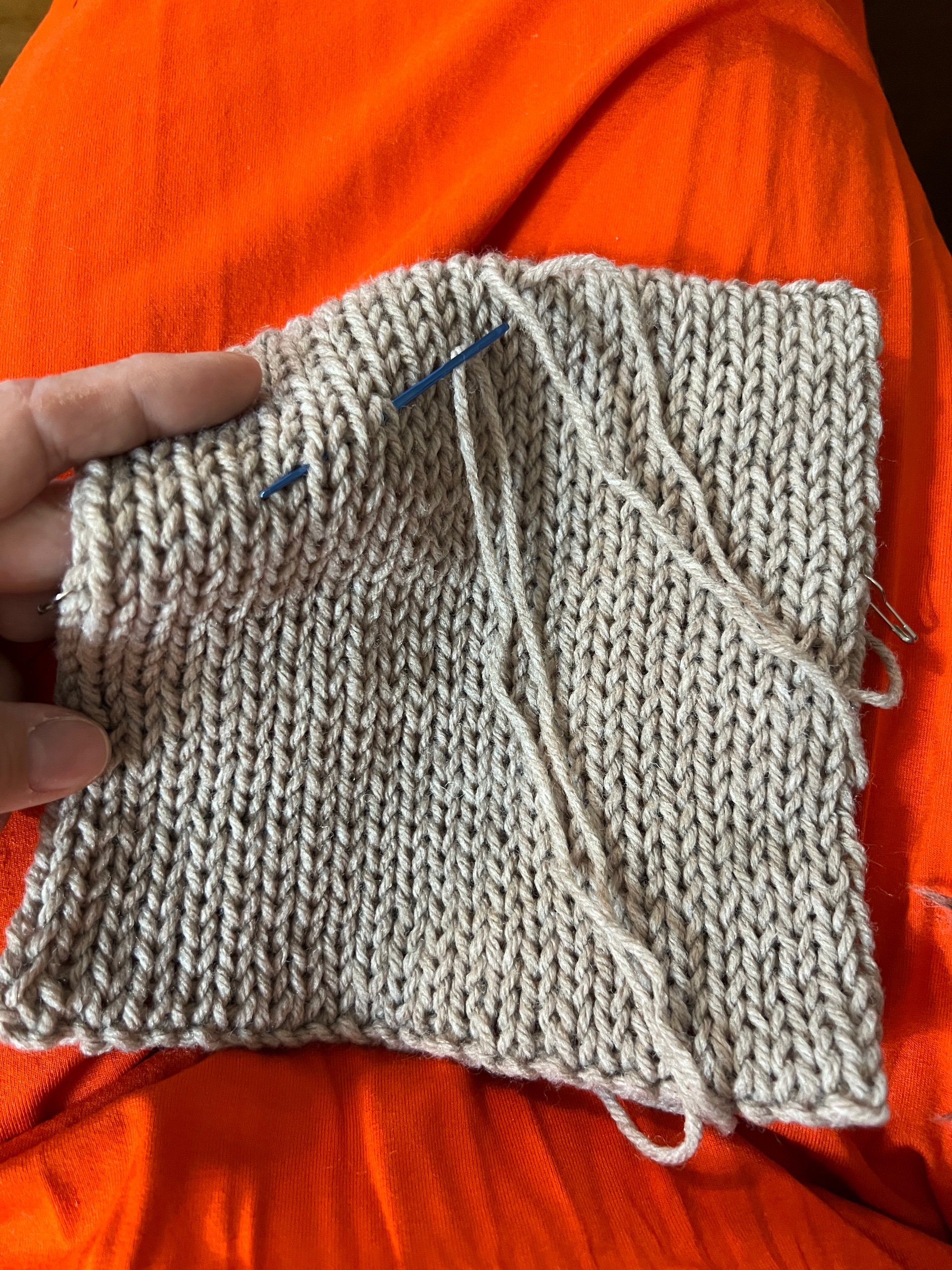

Next I outlined the machine footprint and will need to plot where it will sit on the table.

After conferring with my spouse we decided to turn the table sideways and have the extra support under the table closest to me when using the machine (for most support when using the table). I’ve now traced a circle into the wood and drilled a pilot hole to see if my hand tool with a thin saw blade will work.

The hole wasn’t big enough so I asked our friendly neighbour with their jigsaw (electric saw) the to cut the new pencil outline

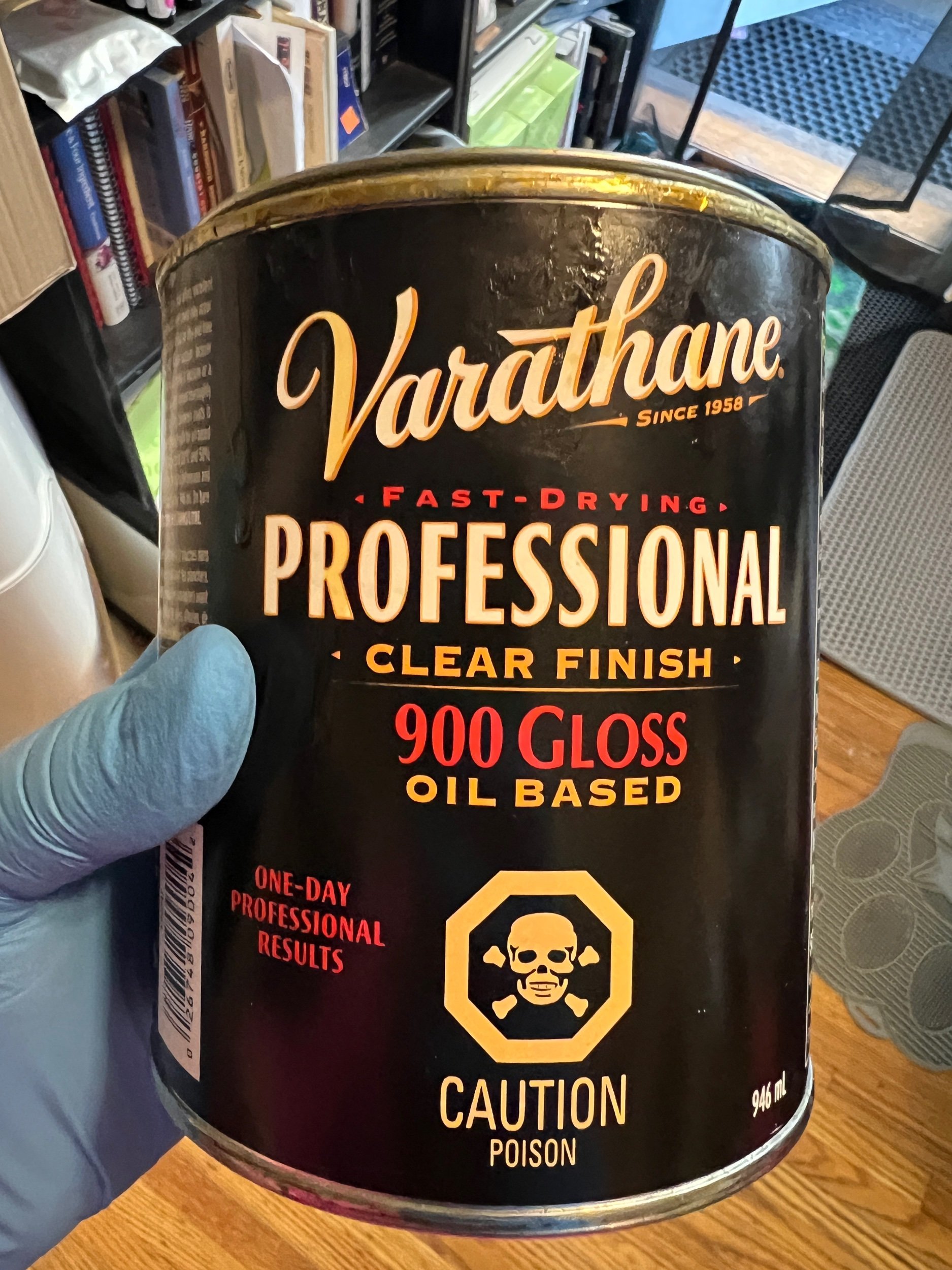

Tonight (June 14/23) this final cut was done. The circle needs to be exactly to the inner edge of each of the feet. I smoothed the surfaces with my Dremel and now it’s perfect .

I found rubber feet for the table and they work great. The setting up of the table has the inner table legs come very close to the outer legs so I trimmed the rubber feet where they slightly collide. It’s still a bit close with the feet and it does fight a bit to fully collapse the table when done (but it still works).

The table is now perfect and ready for easier use of this plastic knitting machine!

Instagram posts: one | two |