My first Lace Carriage venture Nov 9 was a gift for a friend. I worked a Lace Card pattern punch card but it didn’t correctly mimic the pattern card. I felt I used enough weight and didn’t go “fast” but still the full pattern diamond shape not work correctly.

Once I removed the almost 1000 row project I removed the Lace Carriage and looked underneath.

I went onto YouTube and found The Answer Lady video on Adjustment and Testing of the LC2 or 360/260 Lace Carriage. The video is incomplete but reviews a working lace carriage and one that does not.

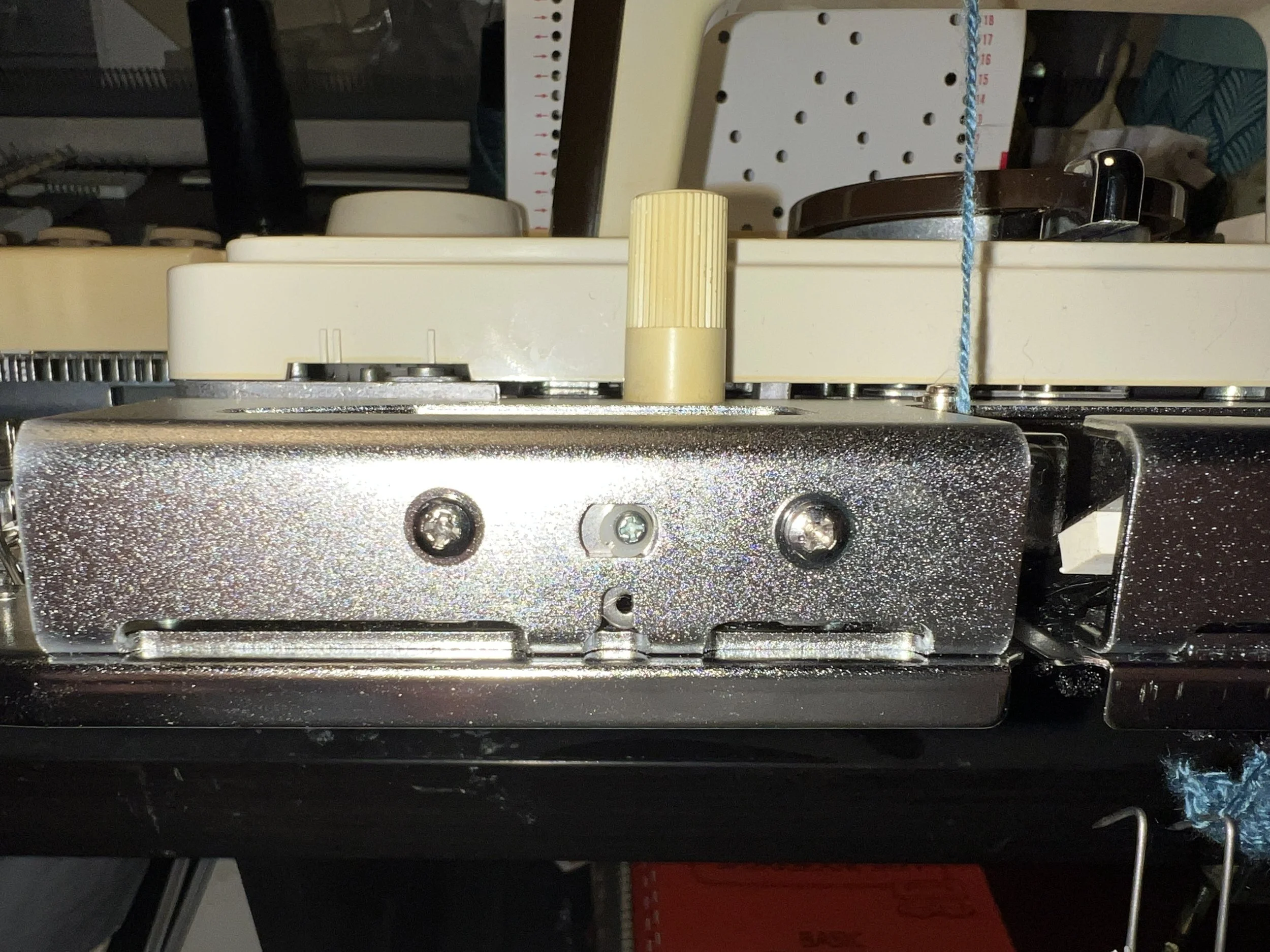

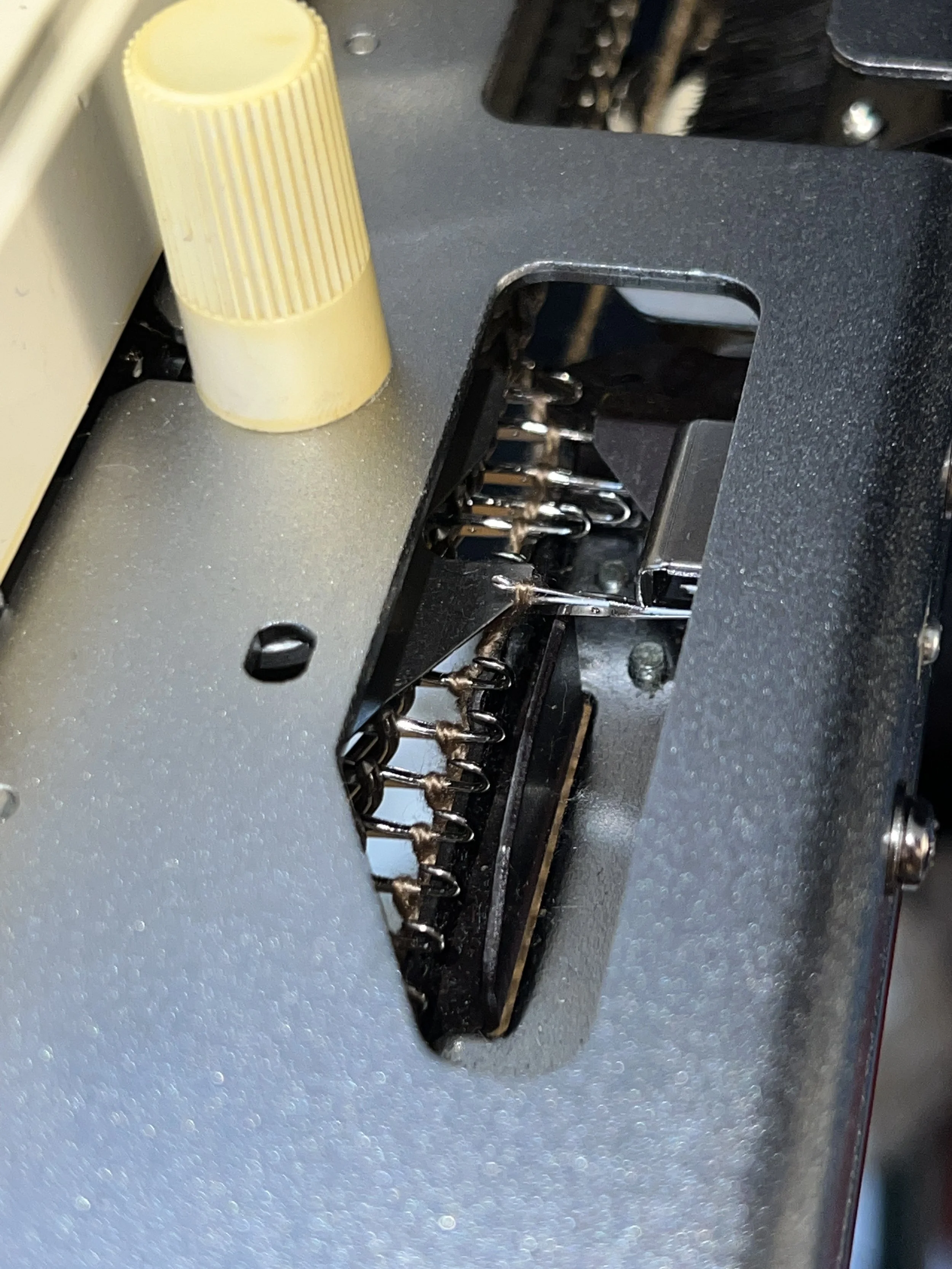

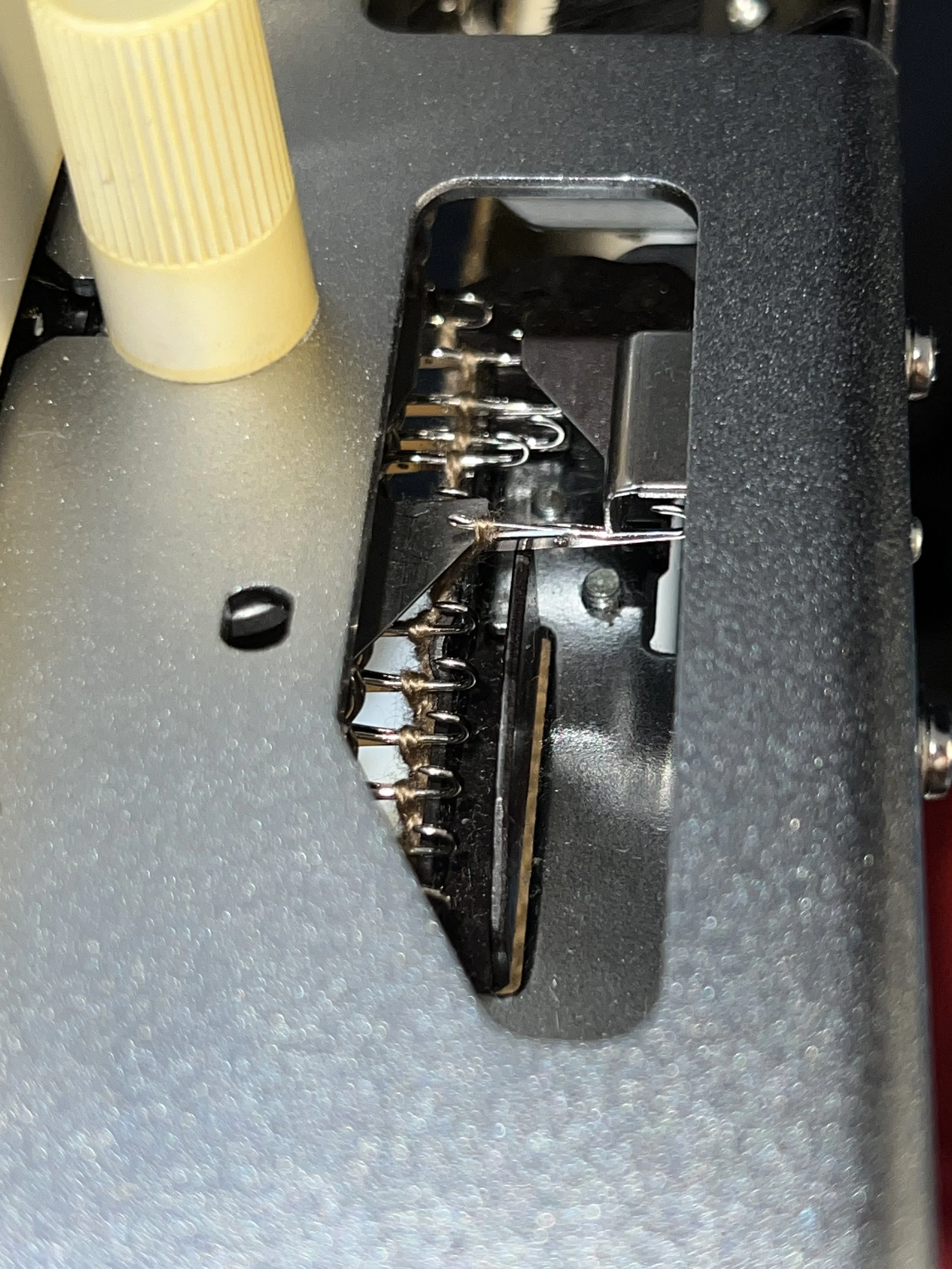

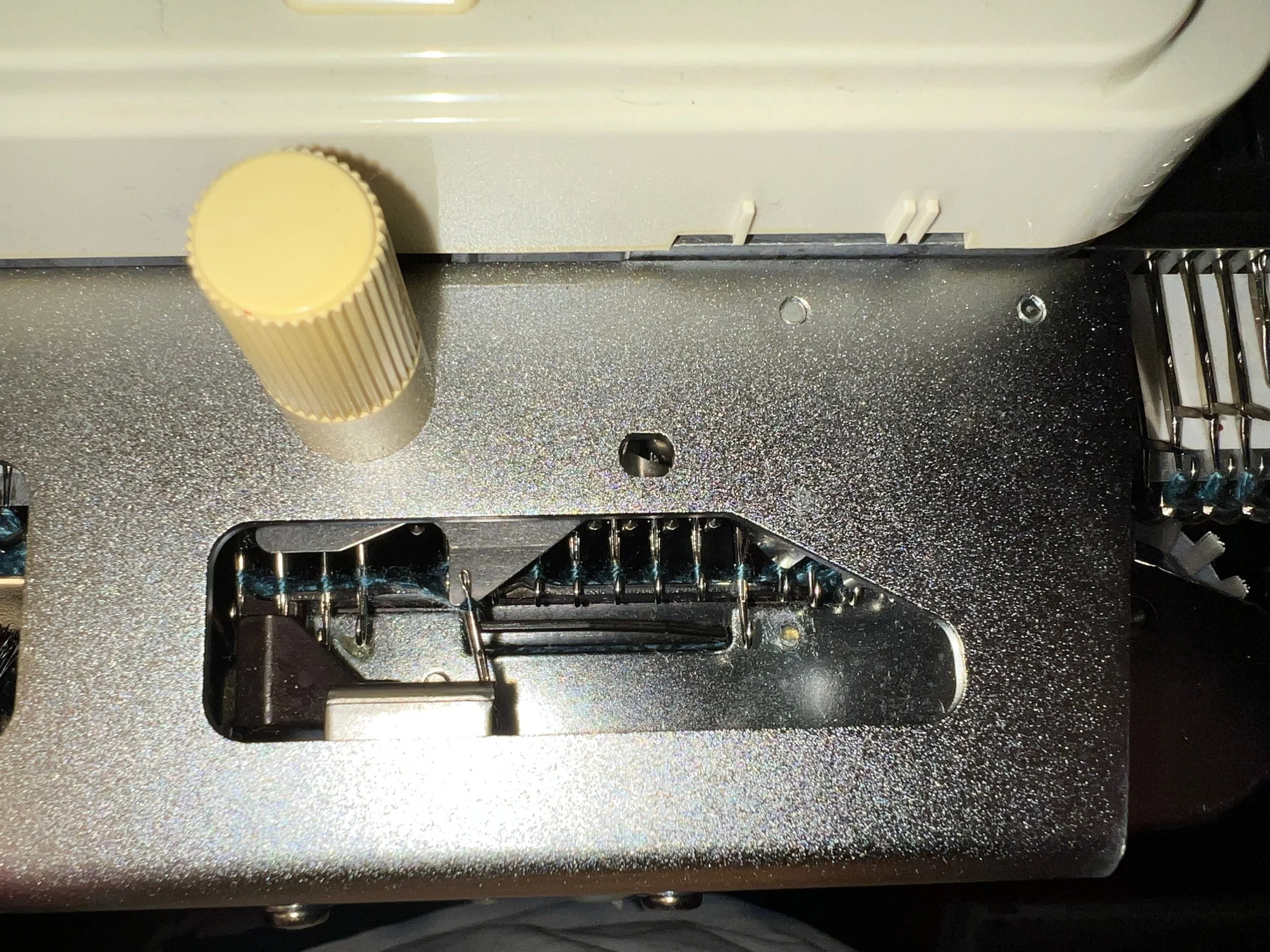

(These two images are of MY machine - the left and the right). They mention the two sides of the carriage that hold a piece within the needle movement area, how the left and right screw manage one setting, a smaller screw and white washer style cam manage another setting and that adjusted together they set the angulation and height of the component that pushes needles down within the mechanism depending on direction being worked. They review that the working one sits 4mm from the top of the carriage and that its mounted evenly.

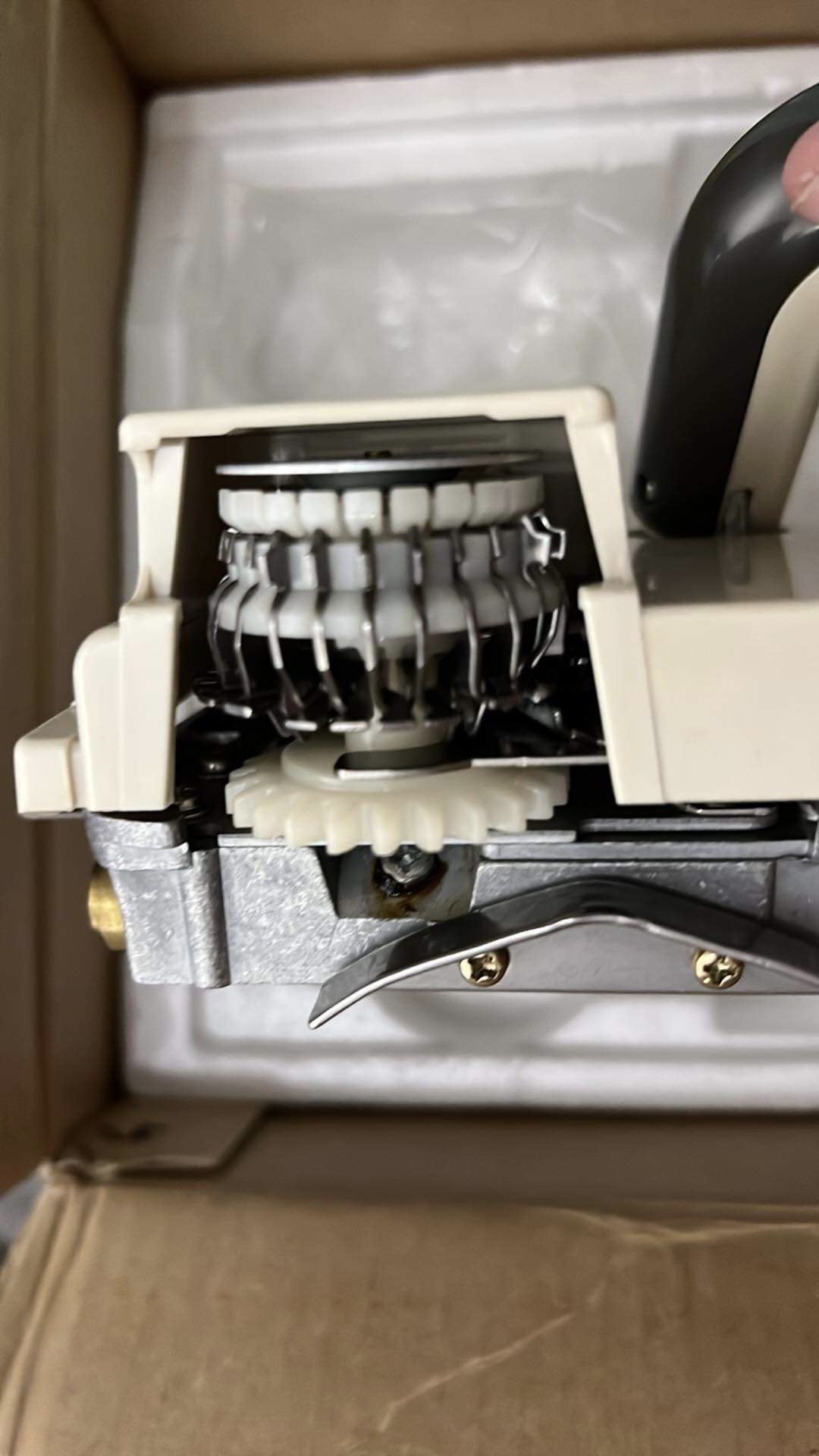

Before adjusting ANYTHING I checked screws etc and found that one of the white barrel patterning components had a loose screw on top - this seemed to make sense why something would be missed. The metal “legs” in that patterning device were initially very loose. (Images shown in this section are reference images only - not of mine).

I also thought it might be important to adjust the screws mentioned in the video above. I should not have done that. Now (even moving slow) the needles are being pushed out of alignment/their gate peg homes as either something is bent or just slightly out of alignment (the patterning still needs a look at though).

We have arranged a servicing of the Lace Carriage this weekend however I hope also to bring the main bed and carriage as well as the machine sat for sometime after the owner passed, was disassembled by someone other than the owner and probably in dire need of a good look over by experienced eyes.