Welcome!

You are here perhaps because you are interested in obtaining a Circular Sock Knitting Machine and are looking for more info. If you already have a CSM please goto the next section “Welcome CSM Owner!”

There is no such thing as a “beginner” CSM. Nor is there a more “easier” or “harder” machine. And you don’t have to buy a NEW machine in order to get a working machine - however being cautious as to where you buy your second-hand or vintage machine (and although machines are usually an investment, try to not seek the “least expensive” as a rule of thumb).

Expect to do some research :) (don’t worry this site is to help you with that!)

YARN!? Note that generally most circular sock machines use a fiber that can only be a certain thickness or thinner - for example fingering weight sock yarn and lighter/thinner.

How thick the yarn can be to be used successfully on a machine depends on the width of the slot of the inserted cylinder - there must be room for the yarn doubled with the needle in each slot. A cylinder is the interchangeable insert that can have different slot counts and the more slots a cylinder has the narrower those slots need to be, so of course the reverse is true to a point. In rare circumstance a slightly thicker fiber might be usable on a lower slot count cylinder (like a 54 slot count over a 72) however often one just needs to try it. See SUPPLIES I LIKE for what a cylinder looks like.

Generally main components on a CSM are machine specific so ensure to get what that specific machine uses.

Newly made or not, most Circular Sock Machines have generically the same construction so it’s a HUGE help to know more about the parts and how they go together regardless to what specific machine you have/get. While this site is geared towards metal circular sock machines, there are now makers of less expensive 3D printed machines. All our combined info on this site is relatable to all circular knitting machines with similar function.

I’ve created two useful videos to dip your toe.

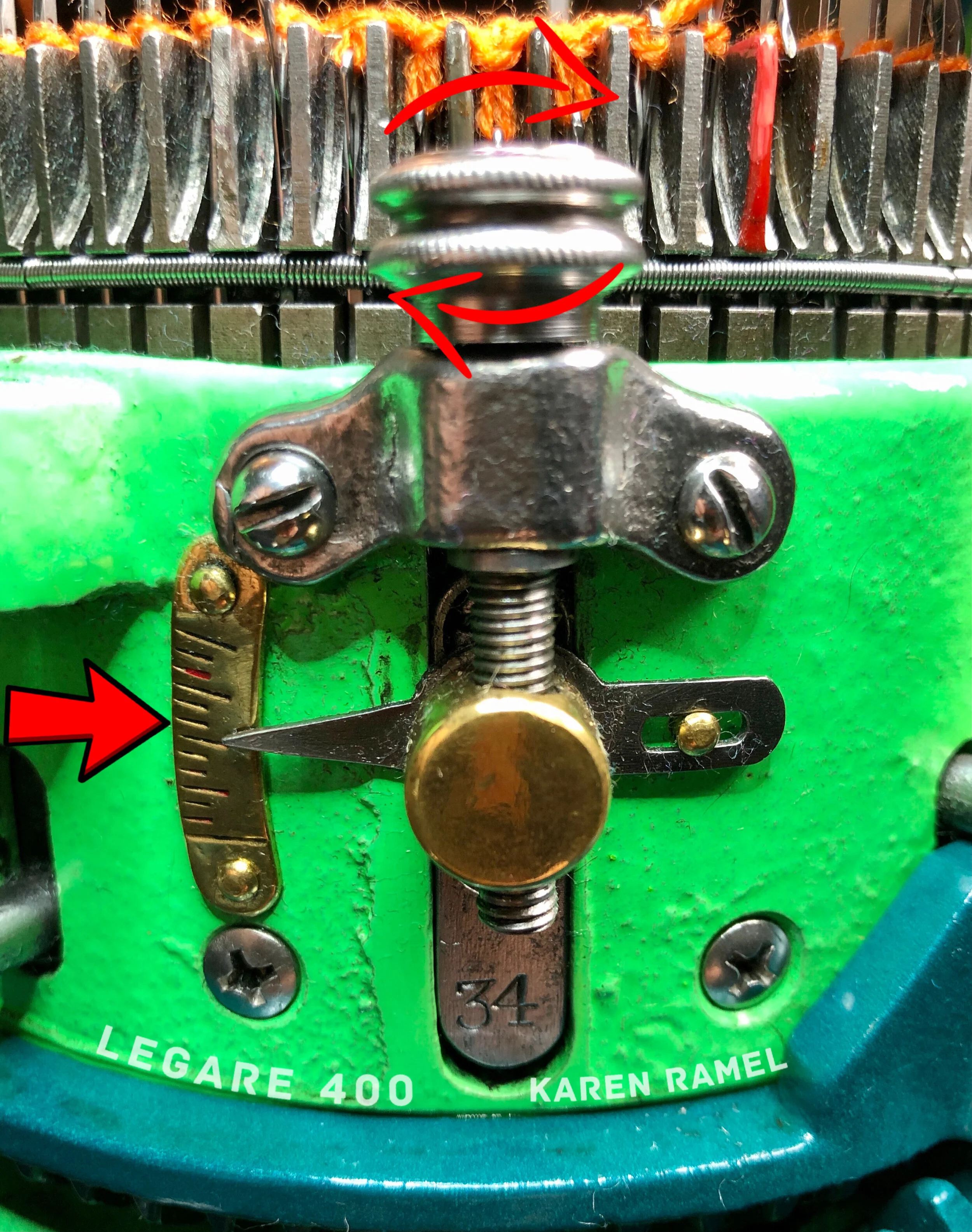

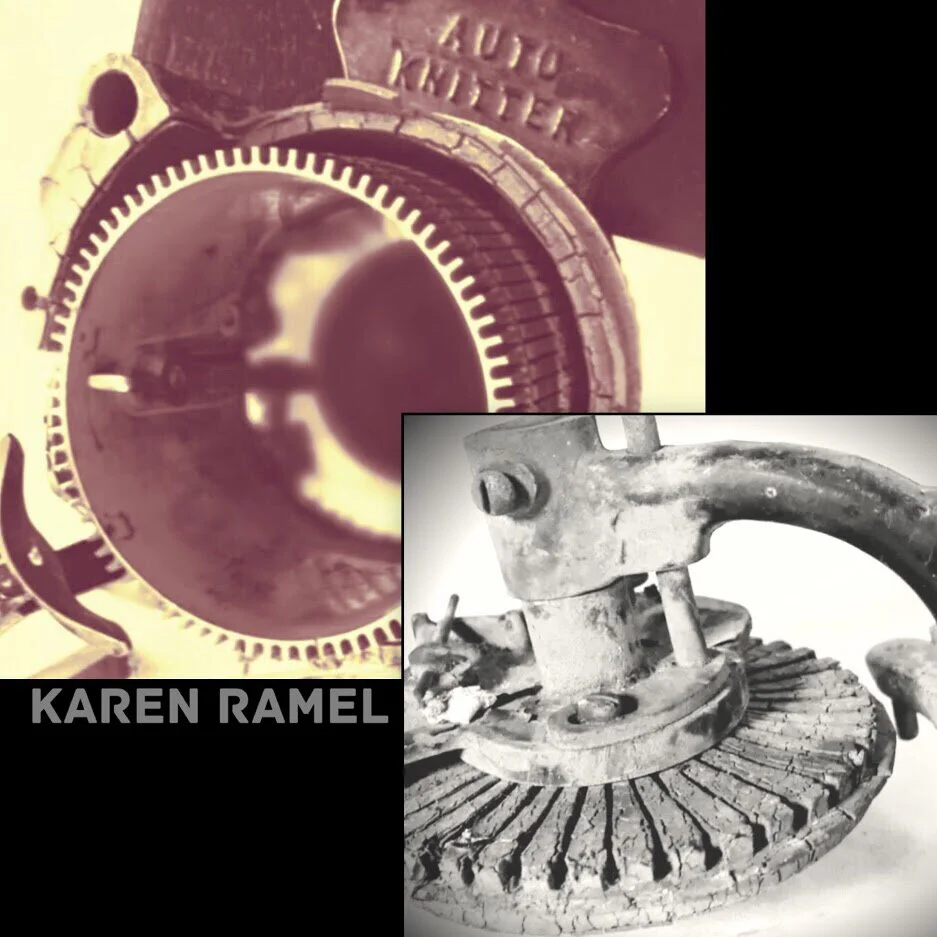

The Legare (Closed Cam). The Autoknitter (Open Cam).

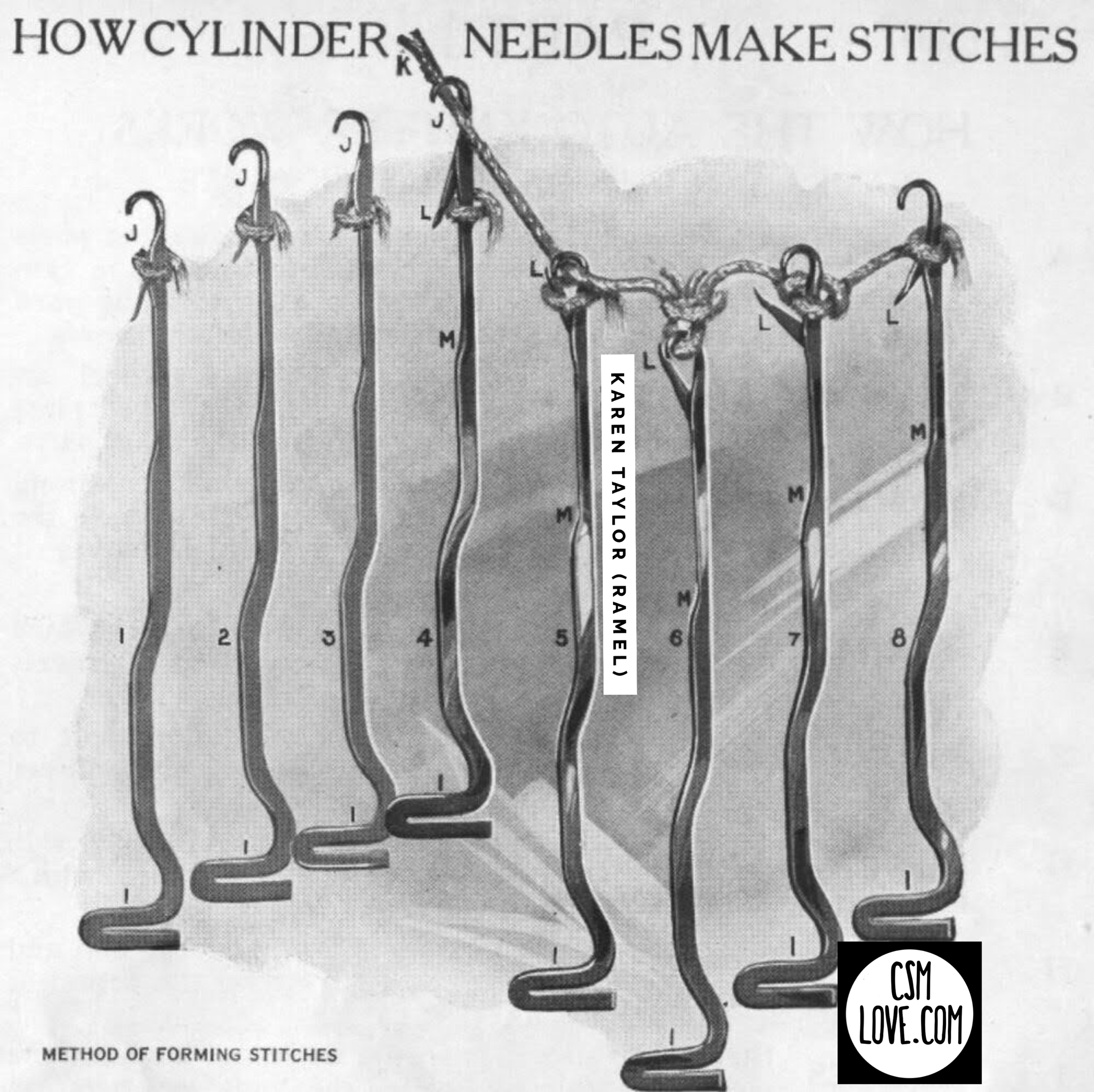

Of all the components, most of the differences are the CAMs. A CAM is simply the metal bits on the inside of the machine shell that raise the needle into work. There are two basic CAM styles - Open or Closed. And with those CAM styles the dial that is turned to loosen or tighten the stitch created - the tension stitch dial - differs. See the image.

Watch the Legare and Autoknitter videos on my website as they explain the CAMS while also introducing the machines themselves (most are very similar).

Personally I prefer the CLOSED CAM machines because:

-it can go in reverse without needing to lift needles so there’s less likely an issue with jamming the cams

-the tension dial on a OPEN CAM is one where the knob can be turned tighter or looser than the machine can actually knit (by design) making it more difficult for new users to find the right setting

-the CLOSED CAM machines never have an issue of the needles improperly travelling onto the wrong side of the CAMS causing the needles to not fully release the latches, causing issues with creating a stitch (see more o the next page and on the Baseline page later)

Some machines with OPEN CAMs are: Erlbacher new machines, Autoknitters (including the newer NZAK Ultimate, Quiknit, and the vintage Gearhart machines).

Some examples of machines with CLOSED CAMs are Legares (AKMC Automatic Knitting Machine Company, the Bi, Creelman Bros Banner Machine, Creelman Bros WorldStar, Caducque Rapide, the Cymbal, Griswold, Harrison Sun Circular, Imperia, Ideal, the Lama, L'Eclaire, La Perfection Bruxelles, Max Geltz, the Rekord, Sameuse, the Vega, the Wikuna).

Want to see what those things are? See pictures of these cams at CSM Misc (Cams)

Why am I mentioning CAMS?

Closed CAM machines like the LEGARE allow you to go in reverse easily without having to lift any needles. Open CAM machine like those mentioned above, require a certain number of cylinder needles to be lifted in order to clear the CAMS of the cylinder needle butts (bottom foot area of each needle) - otherwise when changing directions they get sometimes hopelessly jammed.

Further differences on the OPEN CAM machines can sometimes be seen with their “Upthrow Cams” (teardrop shaped moving parts on the inside of the shell) where some machines have springs on those two parts (they are in pairs on each machine). An example of a machine with spring controlled Upthrow Cams is the new Erlbacher machines - springs translate into a much louder machine as each spring loaded upthrow cam hits a needle butt. However there are also other machines with those same Upthrow Cams without springs like the Autoknitter.

There you have it. That’s the main differences. See the row of images below for the Open CAM Legare (my machine), the Autoknitter and the Erlbacher machines.

*Note Erlbacher has now dropped Gearhart from its name. They are now known as Erlbacher Knitting Machine. They began creating their new machines in the past inspired by the vintage Gearhart 1924 antique machines. They offer a larger diameter machine for hat projects (Bumblebee) and their regular machine. The options they provide is the crankwheel - one “speedster” one “reduced ratio”. Persons often refer to their machine by the crankwheel handle. See more info on their machines on the NEW CSM MACHINE page.

Click on any image to see a bigger view. Note the outer shell (Cam Shell) differences in regards to height to the cylinder and the smaller parts (up throw cams and V Cam) which move the cylinder needles into and out of working position to make a stitch. See more at CSM-Misc for CAM photos

But does the CAM style REALLY matter? No. A working machine is a good machine however a machine you can still get parts for is even a better machine. Buying a vintage machine does not mean you can’t get parts for it - there is a supplier in Quebec Canada that, among the many things, also sells replacement parts, repaints/refurbishes old machines like new machines and more - they are Dave Lord of Chambord CSM (see them on the SUPPLIES menu.)

Locating a Circular Sock Knitting Machine to buy

If you are considering a vintage machine from someone and it doesn’t come with a ribber (YOU WANT A RIBBER) - be sure it was a machine that COULD have a ribber (and that the machine isn’t so old that there was a reason they made upgraded versions of it after that one).

Personally I consider the LEGARE 400 (a vintage machine) to be better than the Autoknitters or vintage Gearharts - mostly due to smoothness of operation, ease to work on the machine without needing to lift needles when going in reverse and finally ease to get parts made from Chambord CSM - although this same supplier does make Autoknitter and other machine parts. Watch my unknitting video for why I love the Legare. HOWEVER there are many happy owners of Autoknitters, vintage Gearhart machines and other vintage European machines. The modern Erlbacher Gearhart machine is based off of the vintage 1924 Gearhart machine, the modern machine is now on its second ribber version.

Suppliers of these machines can be found in the SUPPLIER menu under NEW AND USED CSMS

That’s pretty much it. So then should one buy a vintage or a new machine?

BUT WAIT! Now we are seeing 3D printed CSMs coming into the market. For example see the SUPPLIES for the NEW CSM MACHINES. There is a new maker - Dean and Bean who recently announced ribber development for their 3D printed machine. Yes the machine functions slightly different than a metal machine, but a machine (plastic or not) with a ribber is a FANTASTIC (less expensive) option.

So where can you buy a machine from? I strongly recommend buying from a verified seller so that it is what it should be and gets properly packed/shipped. You don’t have to buy new to get a good machine but you could - see this page. See the SUPPLIES menu for the NEW CSM MACHINES and USED CSM MACHINES.

Failing that you can goto the MISC menu and see my page of Facebook & other Social CSM Groups to join and see if other persons are selling their machine privately. While many of the groups have private sellers posting their machines, one group that’s good to check is the Facebook Circular Sock Machine and Parts for sale listings. Consider insisting on clear, well-lit and up-close photos of all the surfaces of each item - including the cylinder and ribber dial(s). Insist on seeing the machine knitting and ribbing - not just assembled. A person showing the machine working by turning the machine handle (the crankwheel) without yarn on the machine should draw concern as doing so will wrongly collide with needles and damage them. This does not prove it is a working machine.

Haven’t decided what to get yet? Decide whether you want a vintage machine with or without a ribber (I strongly recommend not buying any vintage or new machine without a ribber - you will eventually want to use it trust me). Perhaps read some free online CSM manuals to educate yourself on their workings - see CSM Manuals.

Another way to choose is to see what is out there is to attend a CSM event and note the different machines there or go to a Facebook CSM group and check out the PHOTOS section - the 2.0 group is pretty busy and a good group to start with. Once events are again happening post COVID see the CSKMS.org website and/or here on my site for listed events. I ALWAYS offer free virtual help see GET HELP.

Almost all new and used machine sellers will ship to anywhere in the world. Expect to pay anywhere between CAD$1000-$1800 for a used metal machine from a verified supplier and up to USD$4100 for a new CSM. Any of those suppliers could be asked about payment plans.

BE CAUTIOUS WHEN BUYING OFF EBAY - see our MAIN webpage for the “what inspired this website segment” as to buying from eBay.

Good Luck! (and feel free to write me if you have questions!)

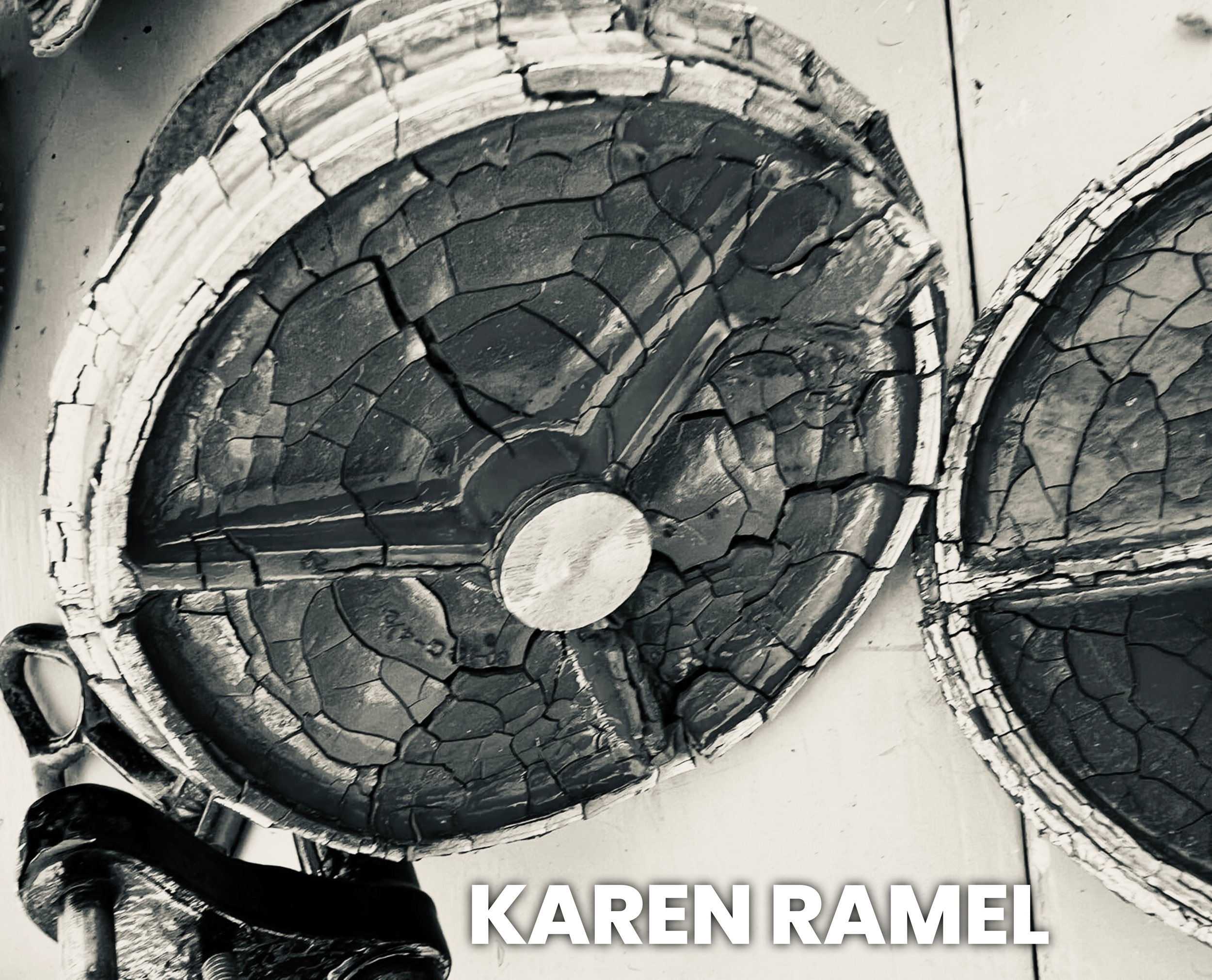

POT METAL

It’s something to keep an eye out for when considering the purchase of vintage Gearhart and some vintage Canadian Autoknitters. Pot Metal refers to tossing an array of not totally ideal metals into the metal melting pot for the creation of those metal parts which translates to components which will, with time, warp, distort or split in unpredictable ways - becoming useless. Its something to be aware of if buying/using these vintage machine models. Components may swell, crumble, crack or no-longer maintain a round shape. Buyer beware.

AUTOKNITTER (its a brand name)

Did you know that there are actually many different Autoknitter branded CSMs out there?

BAK British Autoknitters, CAK Canadian Autoknitters, American Autoknitter, NZAK New Zealand Autoknitter (a current new CSM maker), and the Harmony Autoknitter. Autoknitters.

All of these machines utilize an “Open Cam” (just like the modern Erlbacher Gearhart CSM) that require a certain number of cylinder needles raised in order to work in reverse on the machine.

There are actually quite a vast array of antique CSM brands worldwide!

You find yourself here and you HAVE A CSM?

Onwards to the next page CSM Start 1

THIS PAGE IS A WORK IN PROGRESS. Please stay tuned.