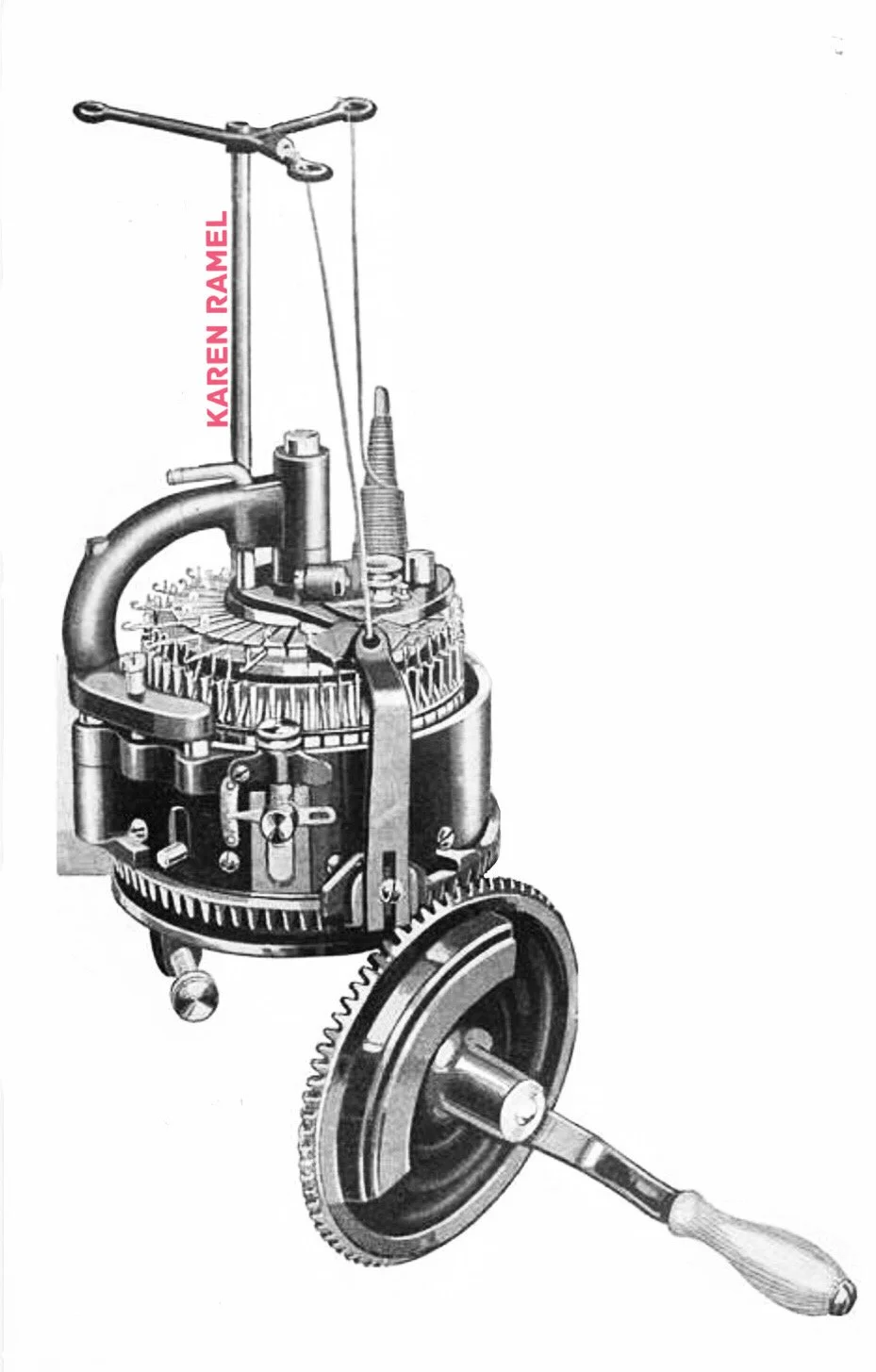

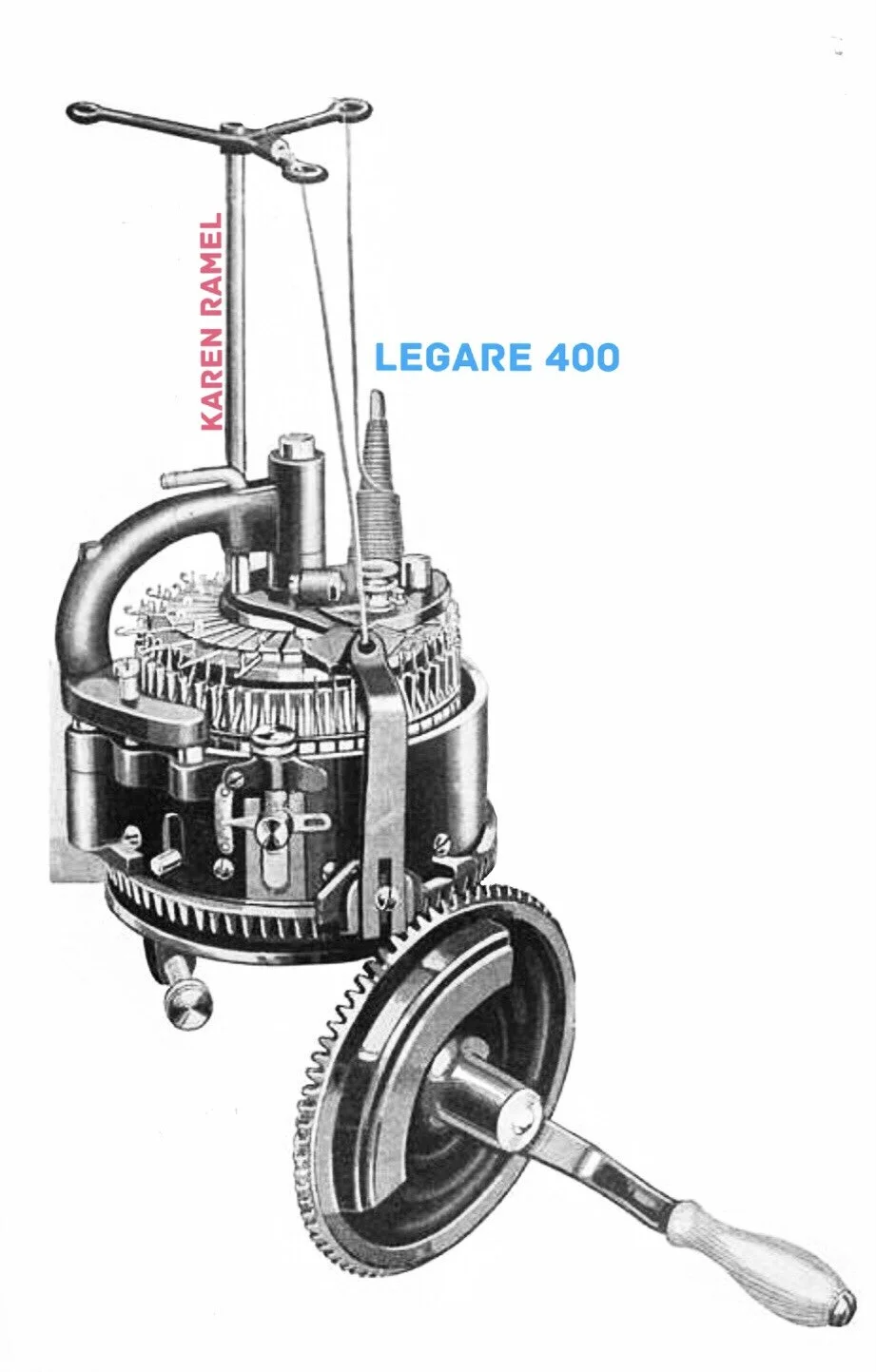

The antique LEGARE Circular Sock Knitting Machine

Announcing my NEW VIDEO: The Legare CSM, How to take apart (and put back together again) shareable YouTube video link: https://youtu.be/JiiYJanqjLA

What mostly makes this CSM different than others is its CLOSED CAM. Watch the Legare video noted above for more information :)

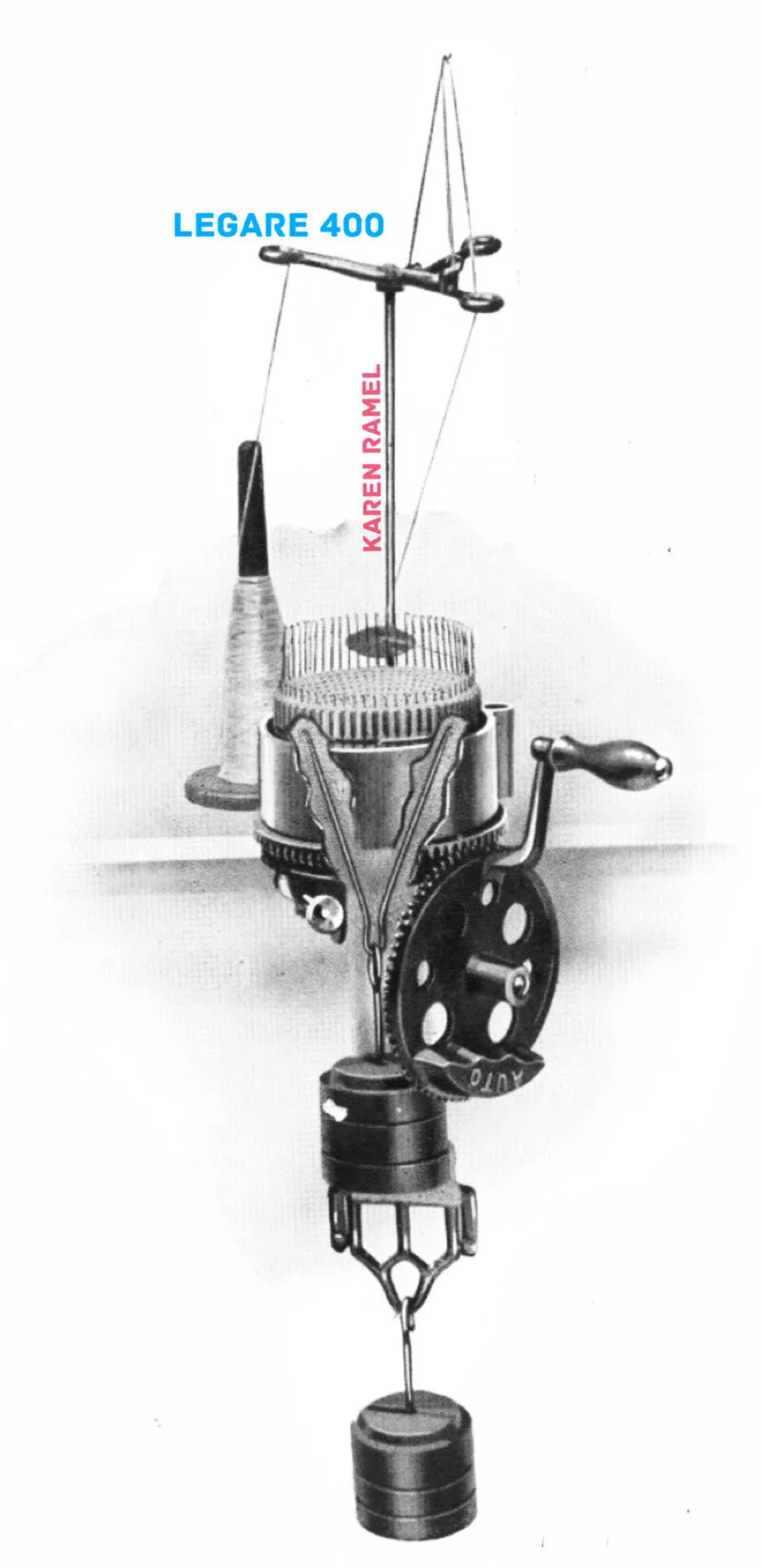

Not sure if you have a

deluxe Legare 400 or a Legare 47?

See this page for the comparison. Cylinders are not directly compatible on the 400 and 47 - further machine and part comparisons are further down this page. Need help identifying after checking the comparison link? Connect on Facebook (preferrable) or email and I can help.

NOTE: Just because the base (bedplate) has a number or label does not mean all the parts are the parts that go with that machine so if you have a machine and something isn’t working correctly you can see the LEGARE VIDEO and/or write me. I can help. :)

ENSURE you have a FULL MANUAL for your Legare - see the CSM START LEARNING menu on the home page for the sequence of informational page which cover this starting as a machine owner at CSM START 1.

Need a part for your LEGARE? Be sure to first look at SUPPLIES I LIKE - VINTAGE

Then contact Dave Lord of Chambord CSM via email. My info page showing their website and contact info is CHAMBORD CSM

Learning how to your your Legare? Check out the CSM Start Learning Pages from page 1

HAVE A LEGARE?

Is yours OLDER or NEWER?

Parts that hint to how newer or older your machine include: the shape of the bedplate and badge, whether the machine has the newer yarn carrier timing screws (my Legare does see below) or not. Older machines don’t have that feature.

See below the newer “Legare 400” version with updated cog ring with adjustable stop (has screws that adjust contact yarn carrier timing)

Then see below for the older machine version where the cog ring doesn’t have adjustable stops.

The part numbers of the main parts will sport different part numbers. The crank wheel might be solid with a different style counterweight (older) or a newer version with the four holes. The tappet might have no part number at all (older) or might sport MMA (newer). And in terms of the Legare “400” compared to the Legare “47” identified by their bed plate part numbers - its not the badge that makes the machine its their parts - on those two machines they differ in terms of the ribber arm, cylinder diameter and tappet.

Having issues trying to get a successful needle to yarn alignment with the Yarn Carrier? You may need to adjust the Yarn Carrier Timing if you have a newer machine like mine.

The newer version has two YARN CARRIER TIMING BOLTS WITH NUT on the COG RING (the COG RING is the flat round part that connects with the crankwheel to move the machine in either direction).

Putting it simply, if you have the two adjuster bolts on the cog wheel (over a non-adjustable nob of metal of the older version) it allows you to lengthen or shorten the distance to the cam shell contact thus adjusting the wave of the stitch. One bolt adjusts forward knitting (counter clockwise) the other bolt adjusts reverse knitting (clockwise). If the Yarn Carrier Timing is off you might not be having the wave of successful needle action at the right point.

If your timing screws with their nut(s) are reversed on the mount, if they are over/under adjusted or missing (and/or not best secured with two nuts) you may not have success trying to knit as the knitting WAVE won’t be in the ideal position.

My machine has the newer version. Here are photos for clarity. A OLDER machine is shown as a drawing for clarity, the green images of of my newer machine. The COG WHEEL on my green machine is the darker green part you see.

Within the last 36 hours I’ve helped two persons with their newer Legares.

One person had the correct timing screw bolts and nuts that somehow were installed backwards, the other person had both bolts but only one had a securing nut and both were maladjusted. In BOTH scenarios if all else was right and they were trying to cast on they would fail as the area to best knit would NOT be in the ideal position at the Yarn Carrier.

This lower right best shows the YARN CARRIER TIMING BOLT connecting with the bright green ribber mount. At this connection you see the machine is pushed to work in the regular forward motion (which is counter clockwise knitting). The other side of the machine is where it connects to go in reverse (clockwise knitting). If either are set with a bolt too long/short then there might be stitch malfunctions. Please consider watching my Legare Video posted at the top of this page and either arranging a GET HELP (see page) session or writing me a direct detailed email.

SUCCESS IN KNITTING ALSO DEPENDS ON BASELINE. See this page.

Have a question? Please email me karenramel@yahoo.com

For further machine and supply information please see my MY SUPPLIES - VINTAGE page.

My vintage Legare was sent to be refurbished see the Oct 19/19 blog post.

IDENTIFICATION OF THESE MACHINES BY DATE?

Often it’s asked what year or how old is one’s machine. Some machines have numbers stamped on the baseplate near the vertical yarn mast, some have no numbers at all, while still others have numbers stamped onto the top edge of the cam shell. Further to that, some Tension Dials have a number posted beneath the dial - one person said it was to note the thread of the screw holes in that component for later identification for machine assembling purposes. No further information provided. To see more see my Legare video quoted at the top of this page. :)

MACHINE COMPARISONS

The Legare was made by the Creelman Co. in Canada. Records indicate a fire may have wiped out any specific production records. However we do know that the Legare had a variety of logo name plates, had a couple different baseplate shapes and maybe two styles of crankwheel. The creelman manual available online for this closed cam machine indicate this machine was made with one of two V Cam styles (the autoknitter open Cam being built with one of three V Cam styles). A V-Cam is the part on the inside of the machine that has a V shape - it’s responsible for the range of stitch size settings when the tension dial is turned. This machine also, at one point, had an upgraded cog wheel which included a yarn carrier adjustment for stitch timing (mentioned above). Basically if your machine has a solid crankwheel (not the four holes of the later models) and lacks the yarn carrier stitch timing upgrade on the cogwheel then your machine is definitely older.

FURTHER…

The Legare 47 cylinders will fit into the Legare 400 machine but not the other way around. The Legare 47 has a slightly smaller diameter than the 400. Cylinders for the 400 while are the same dimensions as some other vintage machines, are not hole compatible with other machines.

The crankwheel for an Autoknitter is not compatible with a Legare due to an extra “tooth” in how it connects on the bedplate. The Autoknitter crankwheel is often pictured with more than four hole cutouts to help visually tell the two crankwheel a apart.

The vintage Gearhart crank has 50 teeth, an Auto Knitter has 72. Some old Creelman machines have a mount that could use both cranks.

The Autoknitter cylinders WILL NOT fit a LEGARE unless the different cylinder screw hole alignment holes are added to accommodate the different screw mount locations on the Bed Plate. Also the ribber attachment hole on an Autoknitter cylinder is in the wrong location for a Legare machine.

Autoknitter dials WILL fit a Legare IF you have an Ribber Post Adapter as the holes are different on the Ribber Dial. Ribber Post Adapters hold the Ribber Dial and Tappet onto the Ribber Arm by means of a screw. This adapter can be purchased from autoknitter.com and perhaps also from Dave Lord (be sure to be specific in what you seek) when/if you email Dave Lord - see Chambord CSM.

Legare and Autoknitter cylinder and ribber needles are fully interchangeable.

The Legare and Autoknitter both feature cam shells where the ribber arm assembly has the large post on the left and smaller stabilizing pin on the right. The Creelman cam shell is reversed and is aligned similar to some European CSMs. Thus the ribber arm assembly for the Creelman is not compatible than those machines shown.

This next section is planned to help identify the parts of the Legare - work in progress

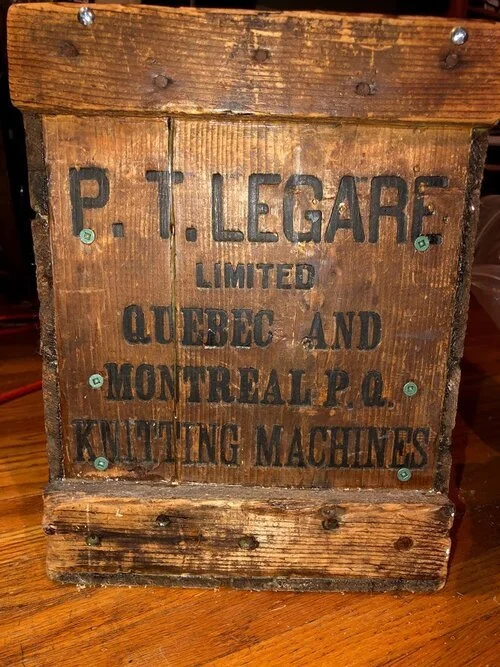

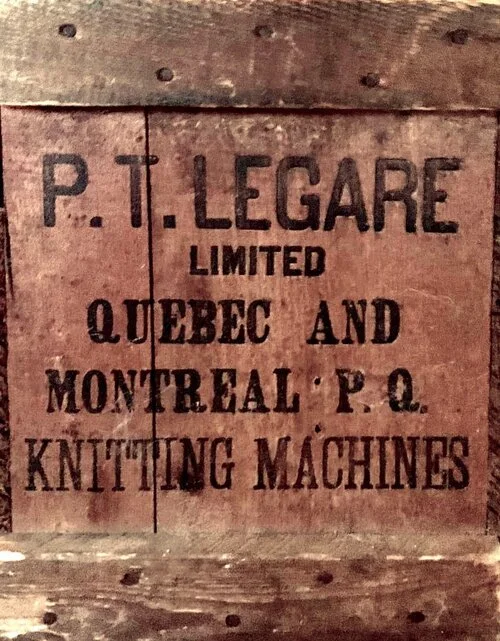

PT Legare photo/document history (page 247 is where csms are mentioned) first page.

Everything is right but something isn’t working correctly?

Have you checked whether your cylinder spring is too loose? If you raise needles and they don’t stay up (and you’re using the correct needles) then there’s a high probability that the cylinder spring is the wrong one or too loose. This is ONE item you should consider having a few on hand (a minimum two for each cylinder you own or thereabouts). See more SUPPLIES I LIKE-VINTAGE

You’ve had success in Casting On and are looking for small tasks to learn to proceed on your own with your CSM? See the CSM START LEARNING menu on the main page and navigate through the sequence of pages to the last link CSM START 4.

Replacement Parts for the Legare 400*

7224 Ribber Dial Axle – Clevis Pin or Tine Pin 5/8 x 3 ½, or 1/2x 3 ½

7419 Ribber Arm Pin – Tine Pin ¼ x 2” with a Hair Pin Clip .047 Dia x19/32”L

7449 Needle Cylinder Lever screw – 6/32 x ¼ machine screw, flat head brass

7404 Crank Wheel Stud – 12/24 x ½ or 12/32 x ½ round head machine screw

Yarn Carrier Screw- 10/24 x ½ or 10/24 x 3/8 machine screws round head phillips

Yarn Stand Top 6/32 x ¼ machine screws flat head (for holding in the Take-up Lock)

Take-up / Heel Spring screw- 6/32 x ¼ round head machine screw

Yarn Stand Top to hold on rod – between a 8/32 and a 10/32 – can’t find exact fit

The exact current screw or bolt your machine might be missing may be best found by contacting someone who refurbishes vintage machines. Whether some time in the past one or multiple screws were striped and the hole re-tapped (new screw configured to fit) isn’t anything anyone can dictate for a machine we haven’t followed it’s history on (unless it’s always been yours from when it was bought new).

My machines

I have two fully compatible machines: the Legare 400 vintage (machine which was refurbished by Dave Lord of Chambord CSM October 2019) and the Chambord CSM AccuKnitter (which is a modern work of art based on the Legare machine).