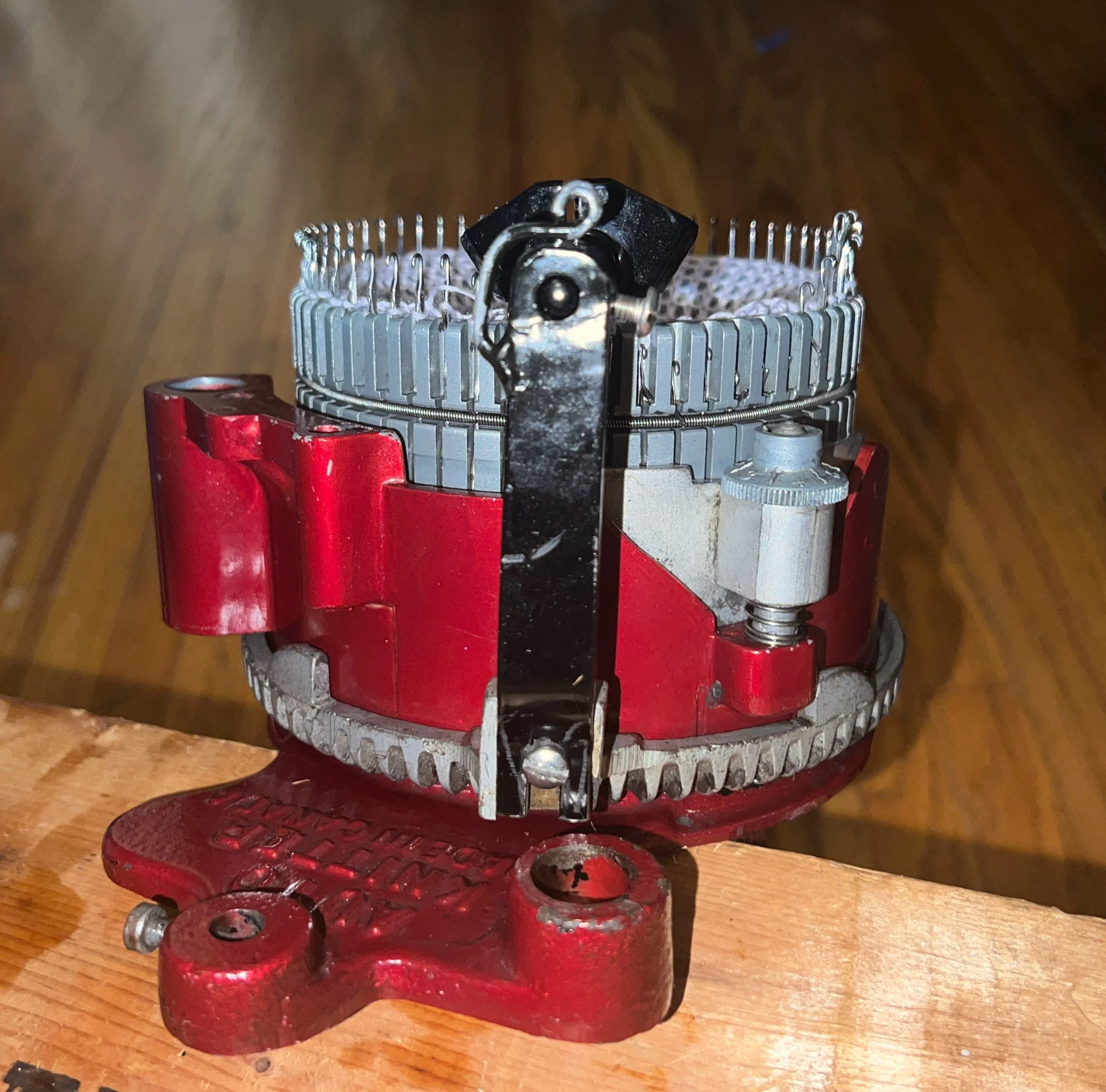

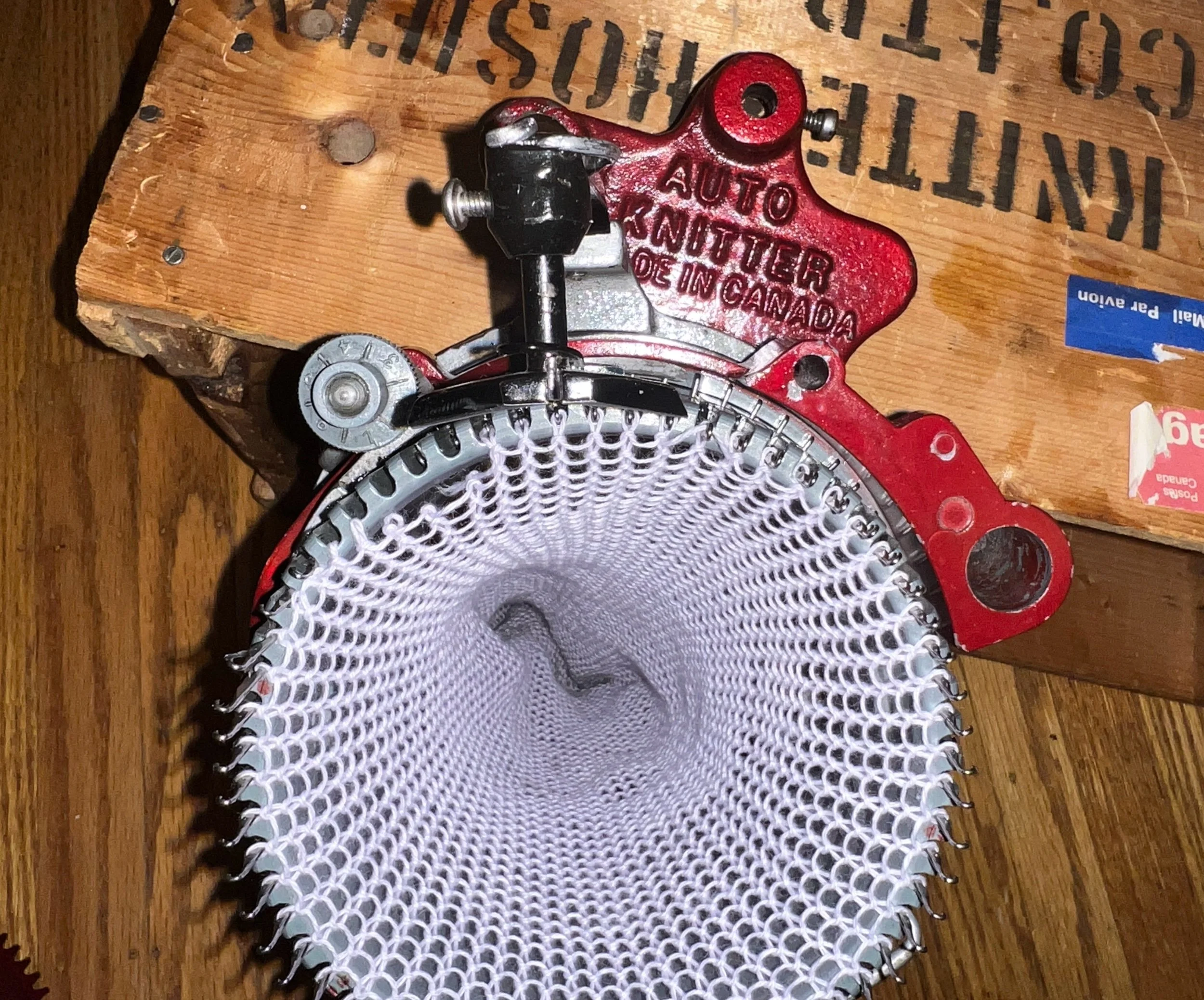

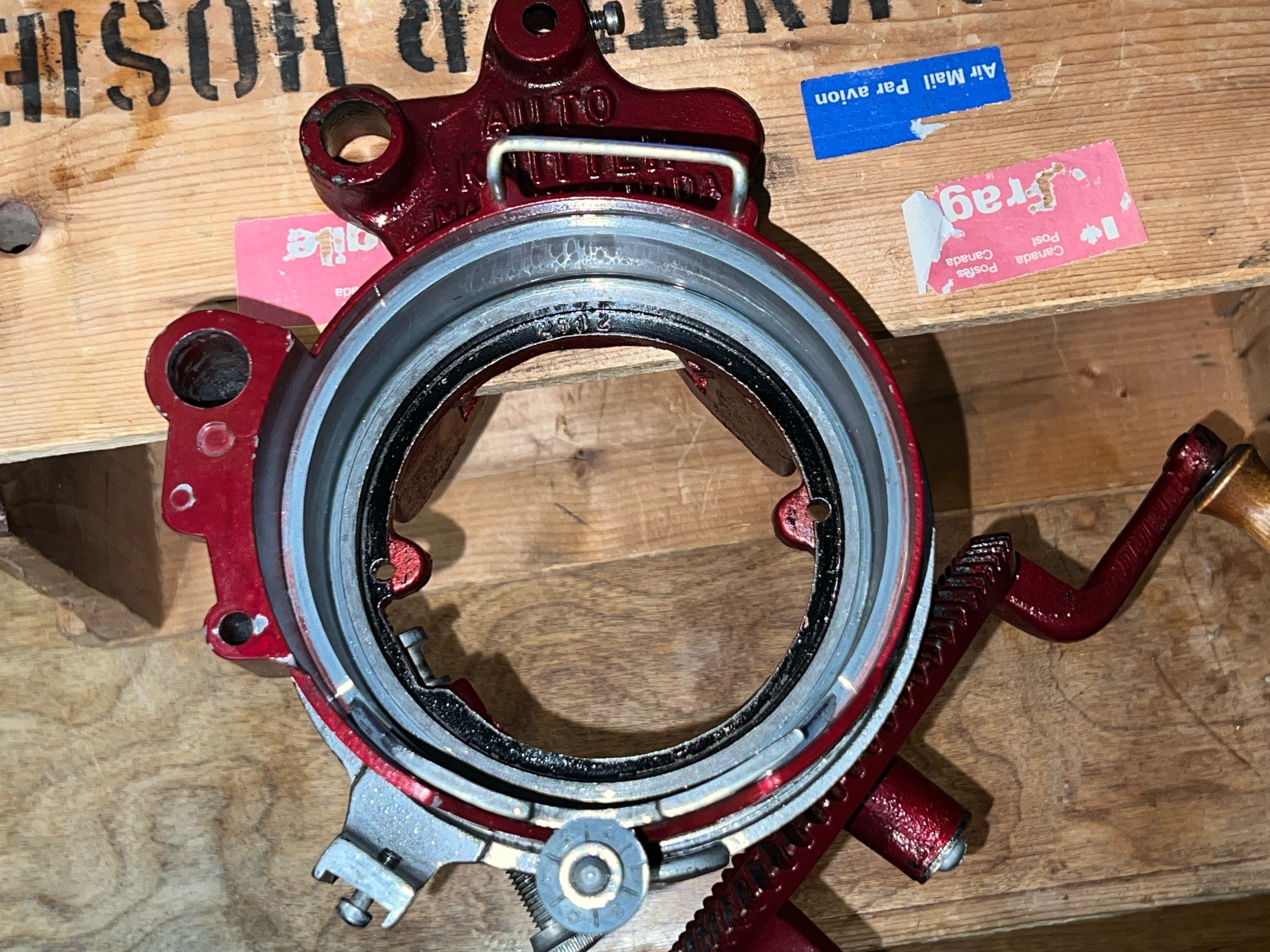

The antique Autoknitter Circular Sock Knitting Machine

What mostly makes this CSM different than others is its a OPEN CAM.

BEFORE you do anything with your OPEN CAM machine please watch this video:

Watch Youtube video - the shareable link: https://youtu.be/NApUY51OOqs

This video will familiarize you with the basic components of this style machine and will help you prevent pricey cylinder needle damage.

Learning how to use your CSM? Check out the CSM Start Learning Pages from page 1

SUCCESS IN KNITTING ALSO DEPENDS ON BASELINE. See this page.

Have a question? Please email me csmloveinfo@gmail.com

SUCCESS!?

You’ve had success in Casting On and are looking for small tasks to learn to proceed on your own with your CSM? See the CSM START LEARNING menu on the main page and navigate through the sequence of pages to the last link CSM START 4.

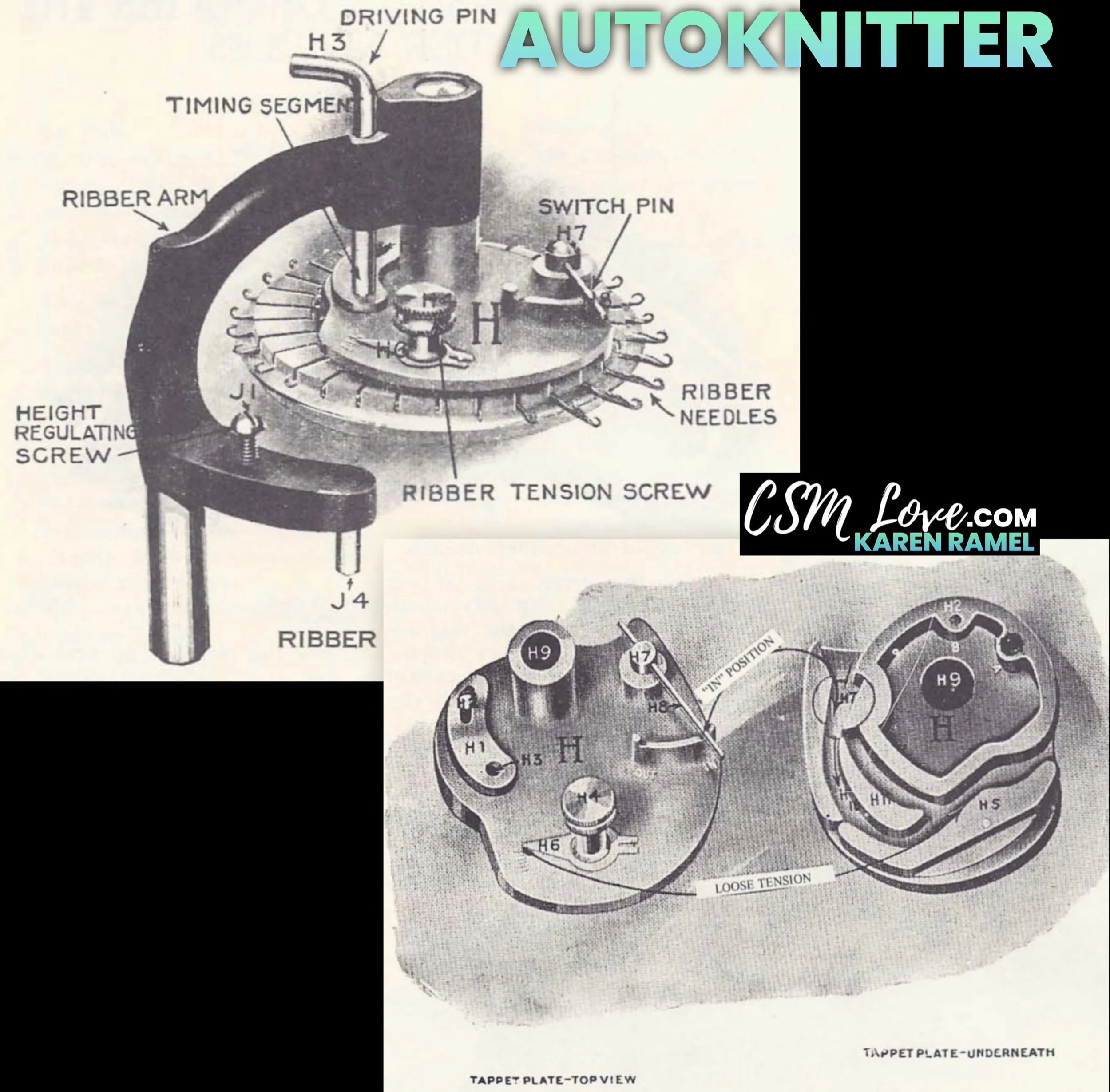

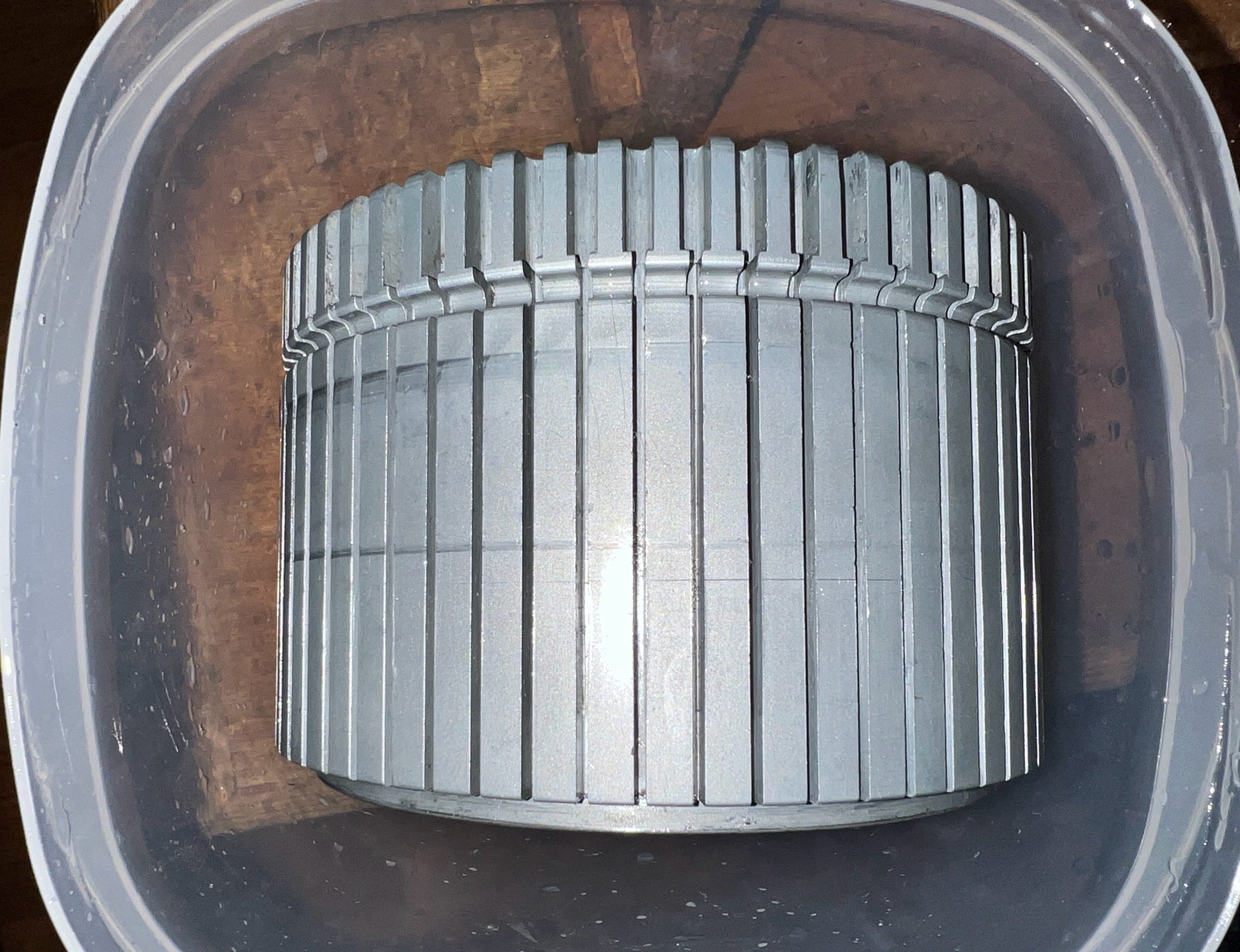

The Ribber Setup

Tappet, Ribber Dial, Ribber Setup, Ribber Dial Post

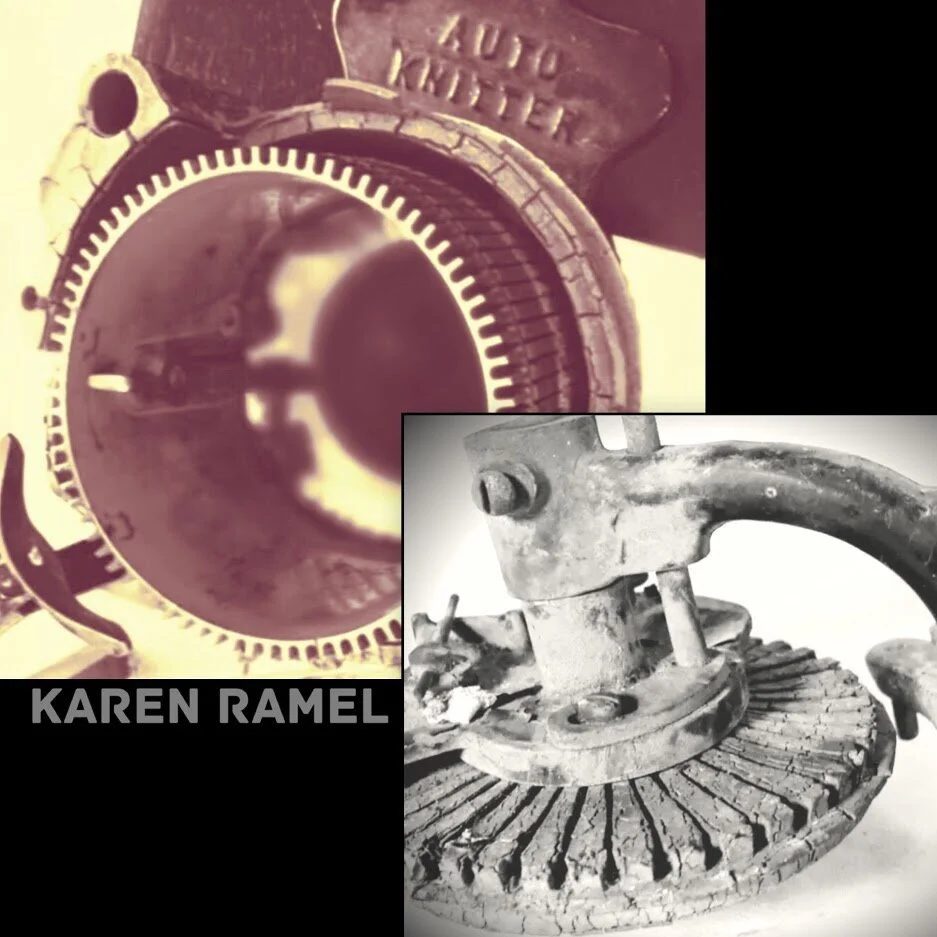

Does your vintage machine have broken down, or warped parts? Pot Metal might be an issue see more info on the CSM START page.

TROUBLE SHOOTING

I’ve helped MANY machine users all over from in-person to video conferencing.

See the blog entries:

Everything is right but something isn’t working correctly?

Have you checked whether your cylinder spring is too loose? If you raise needles and they don’t stay up (and you’re using the correct needles) then there’s a high probability that the cylinder spring is the wrong one or too loose. This is ONE item you should consider having a few on hand (a minimum two for each cylinder you own or thereabouts). See more SUPPLIES I LIKE-VINTAGE

When everything is correct sometimes the cylinder needle and upthrow CAMs can be the issue where cylinder needles aren’t rising high enough to make a correct stitch. Watch this short video.

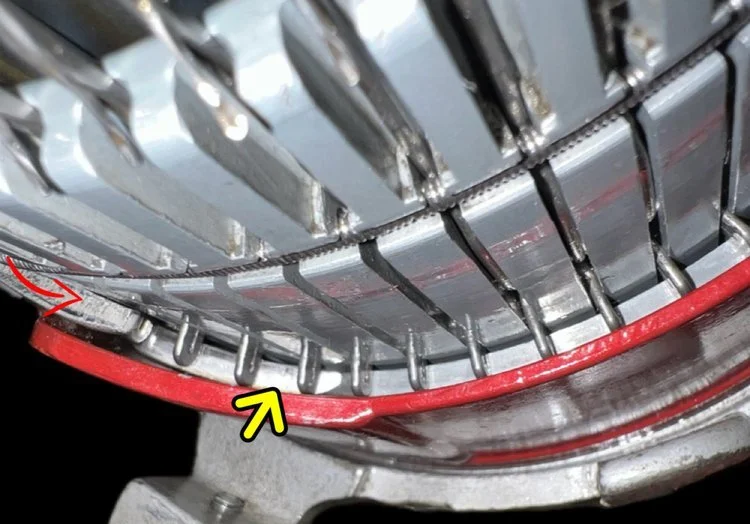

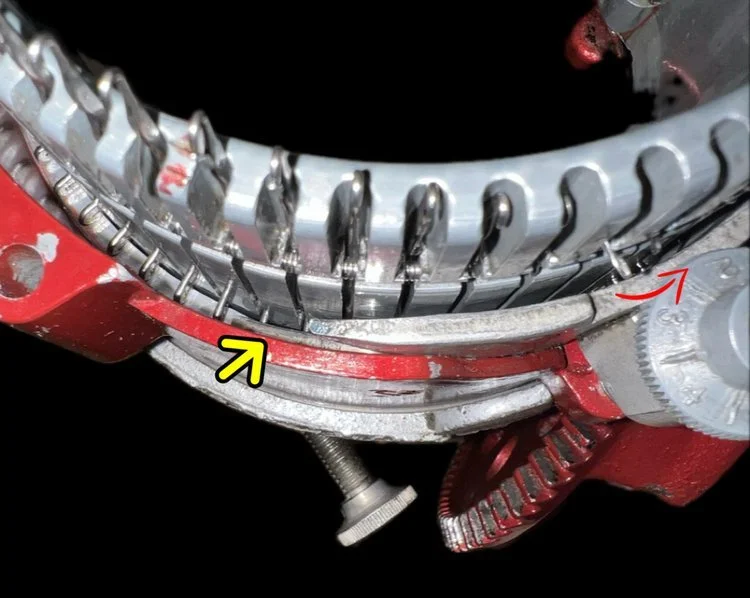

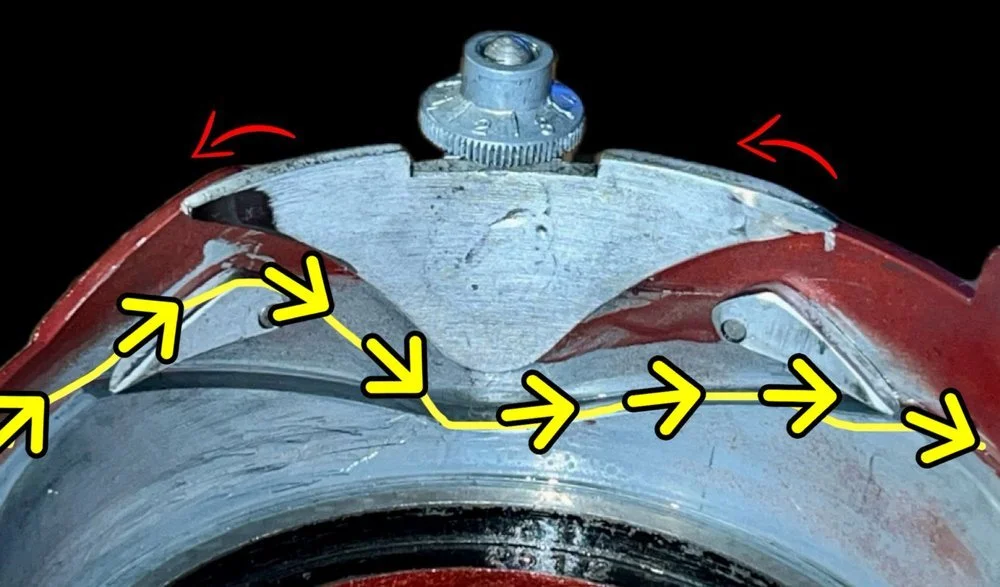

About OPEN CAM machines (like AutoKnitters, the Cooperative CSM, the Money Maker CSM, vintage Gearhart and modern Erlbacher machines): If correctly assembled and attempting to later cast on and noting the needles aren’t correctly going high enough to release the trapped latch - the needles aren’t correctly moving to create a stitch (with the machine at the correct tension), there’s a high probability the upthrow cams or cam lifters, the things that look like a teardrop, are riding on top of the needle butts instead of below.

If 6 needles are lifted out of action, crank slowly forward, this allows the cams to drop down. Once these needles are free of this area they should be pushed down into working position, knitting can proceed.

An image of the upthrow CAM in the wrong alignment

For more info see CSM STARTCSM3

Are the needles in the cylinder not going all the way down?

Taking the cylinder off the machine, ensure a needle worked in each slot, can easily move up and down. This rules out debris or cylinder warp. This is how I found one slot slightly thinner and causing issues.

If things are still not working ensure that when the cylinder is inserted into the machine that the screws are gently tightened evenly - don’t tighten one screw super tight then do the other - instead gently finger tighten one, do the other then tighten both.

Ensure there’s sufficient oil.

When using the machine ensure the tension dial is set at a workable setting - the open CAM machine cannot successfully knit at all the possible tension dial settings. Please review Zeroing your Tension Dial - an essential easy way to set and duplicate that setting again and again later. See TECHNIQUES for “Tension Dial Setting” or review all new user help under the CSM START LEARNING menu.

ENSURE you have a FULL MANUAL for your machine - see the CSM START LEARNING menu on the home page for the sequence of informational page which cover this starting as a machine owner at CSM START 1.

Need a part for your Autoknitter? Be sure to first look at SUPPLIES I LIKE - VINTAGE and the extra handy supplies SUPPLIES I LIKE

Dave Lord of Chambord CSM makes almost everything one could need on or for a CSM contact them via email. My info page showing their website and contact info is CHAMBORD CSM

IDENTIFICATION OF THESE MACHINES BY DATE?

Often it’s asked what year or how old is one’s machine. Some machines have numbers stamped on the baseplate near the vertical yarn mast, some have no numbers at all, while still others have numbers stamped onto the top edge of the cam shell. No further information provided. when it comes down to it - unless you have original paperwork on your vintage machine the exact date isn’t possible.

MACHINE COMPARISONS

Vintage Autoknitters were fabricated in Europe, the United States and Creelman Co in Canada.

The creelman manual available online for this open cam was being built with one of three V Cam styles. A V-Cam is the part on the inside of the machine that has a V shape - it’s responsible for the range of stitch size settings when the tension dial is turned.

FURTHER…

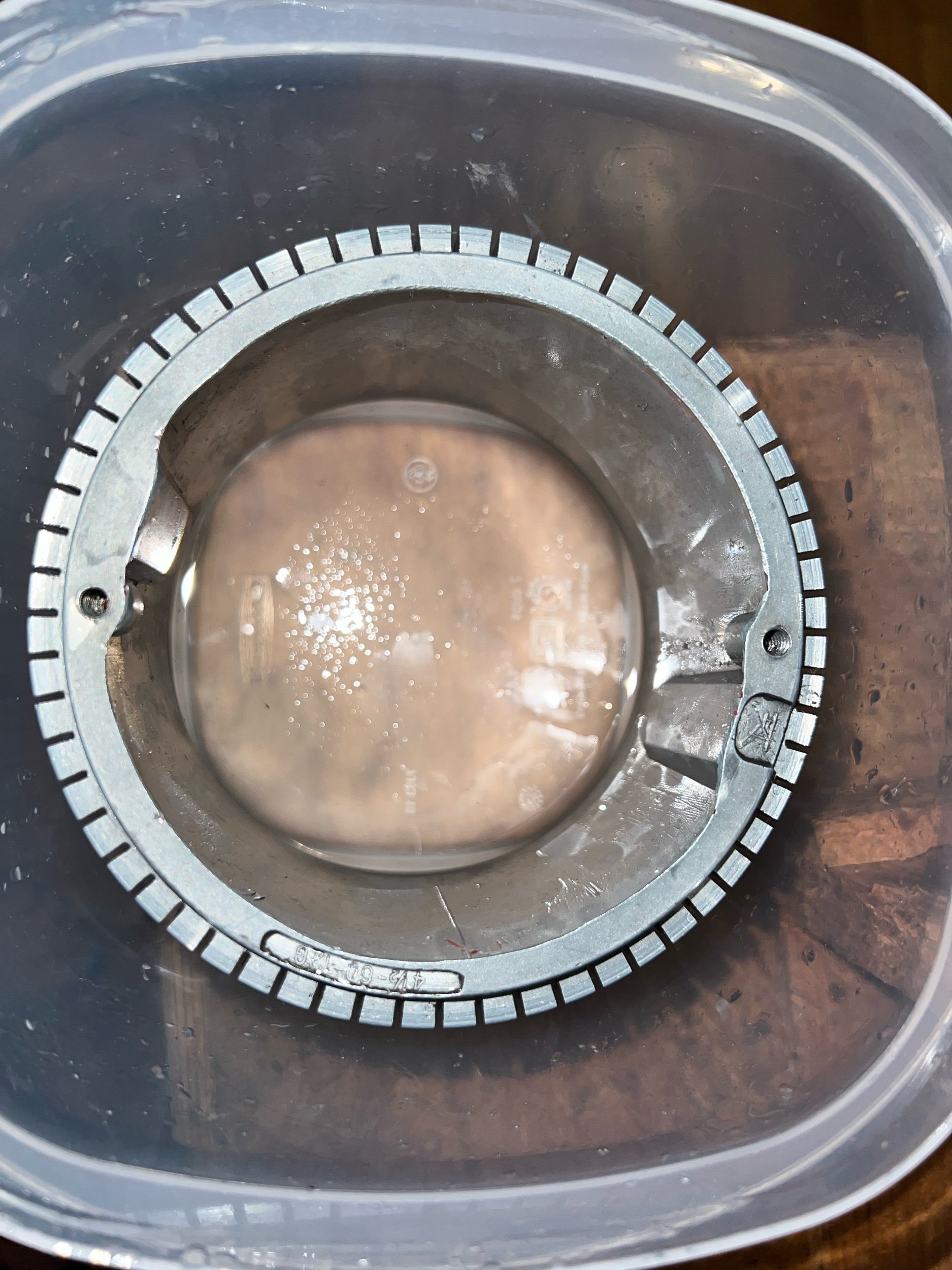

The crankwheel for an Autoknitter is not compatible with a Legare due to an extra “tooth” in how it connects on the bedplate. The Autoknitter crankwheel is often pictured with more than four hole cutouts to help visually tell the two crankwheel a apart.

The vintage Gearhart crank has 50 teeth, an Auto Knitter has 72. Some old Creelman machines have a mount that could use both cranks.

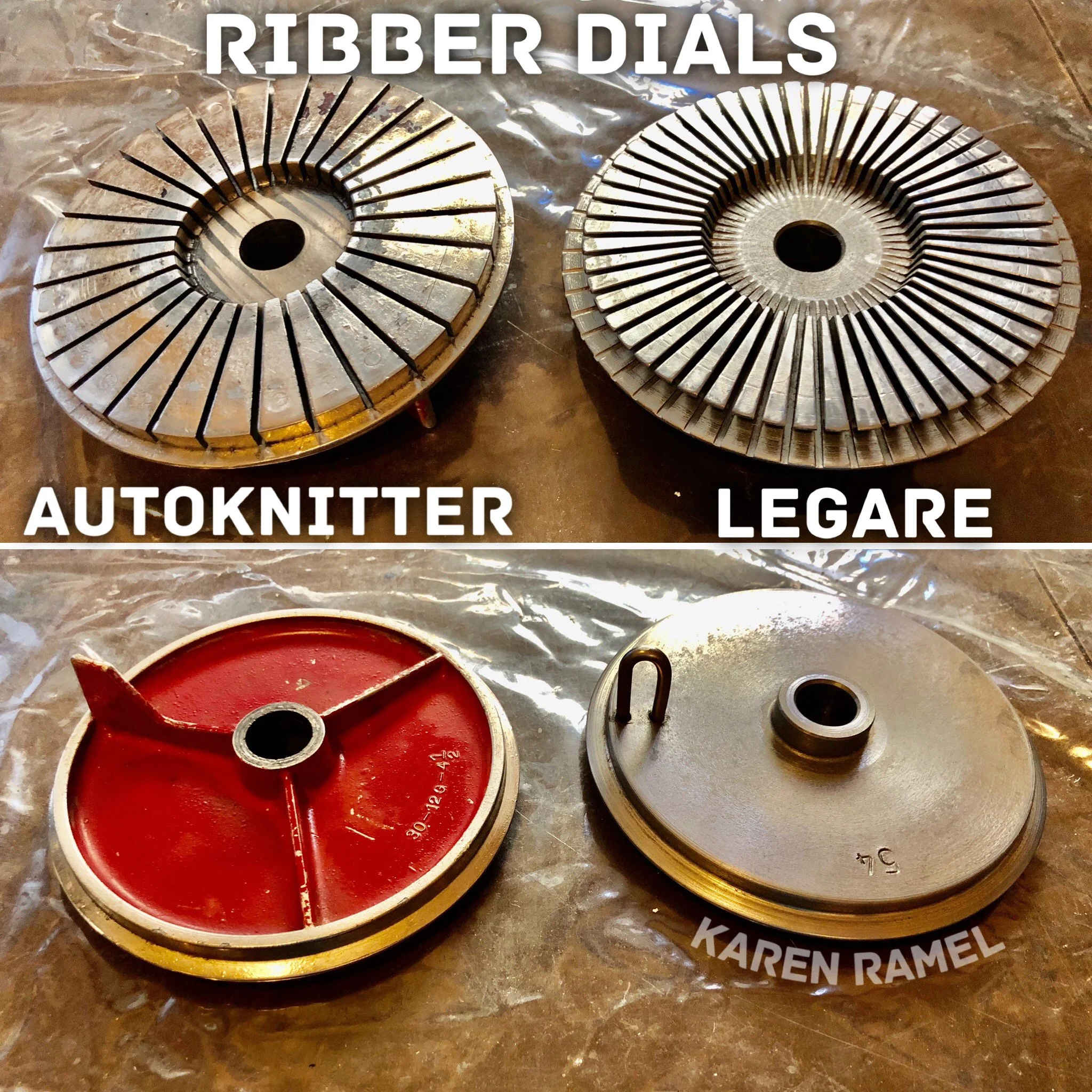

The Autoknitter cylinders WILL NOT fit a LEGARE unless the different cylinder screw hole alignment holes are added to accommodate the different screw mount locations on the Bed Plate. Also the ribber attachment hole on an Autoknitter cylinder is in the wrong location for a Legare machine.

Autoknitter dials WILL fit a Legare IF you have an Ribber Post Adapter as the holes are different on the Ribber Dial. Ribber Post Adapters hold the Ribber Dial and Tappet onto the Ribber Arm by means of a screw. This adapter can be purchased from autoknitter.com and perhaps also from Dave Lord (be sure to be specific in what you seek) when/if you email Dave Lord - see Chambord CSM.

Legare and Autoknitter cylinder and ribber needles are fully interchangeable.

The Legare and Autoknitter both feature cam shells where the ribber arm assembly has the large post on the left and smaller stabilizing pin on the right. The Creelman cam shell is reversed and is aligned similar to some European CSMs. Thus the ribber arm assembly for the Creelman is not compatible than those machines shown.

Replacement Parts for the Autoknitter*

7224 Ribber Dial Axle – Clevis Pin or Tine Pin 5/8 x 3 ½, or 1/2x 3 ½

7419 Ribber Arm Pin – Tine Pin ¼ x 2” with a Hair Pin Clip .047 Dia x19/32”L

7449 Needle Cylinder Lever screw – 6/32 x ¼ machine screw, flat head brass

7404 Crank Wheel Stud – 12/24 x ½ or 12/32 x ½ round head machine screw

Yarn Carrier Screw- 10/24 x ½ or 10/24 x 3/8 machine screws round head phillips

Yarn Stand Top 6/32 x ¼ machine screws flat head (for holding in the Take-up Lock)

Take-up / Heel Spring screw- 6/32 x ¼ round head machine screw

Yarn Stand Top to hold on rod – between a 8/32 and a 10/32 – can’t find exact fit

The exact current screw or bolt your machine might be missing may be best found by contacting someone who refurbishes vintage machines. Whether some time in the past one or multiple screws were striped and the hole re-tapped (new screw configured to fit) isn’t anything anyone can dictate for a machine we haven’t followed it’s history on (unless it’s always been yours from when it was bought new).

Instagram posts: June 15/19 Gearhart | Sep 1/19 Gearhart | Jan 12/20 Autoknitter video |

The Upgraded Hybrid Open Cam Cooperative CSM

See the VIDEO - shareable YouTube link: https://tinyurl.com/UpgradedhybridCooperative