Nov 2019 first upgrades to this table

Nov 2019 upgrades finished with event photo shared

An UPDATE

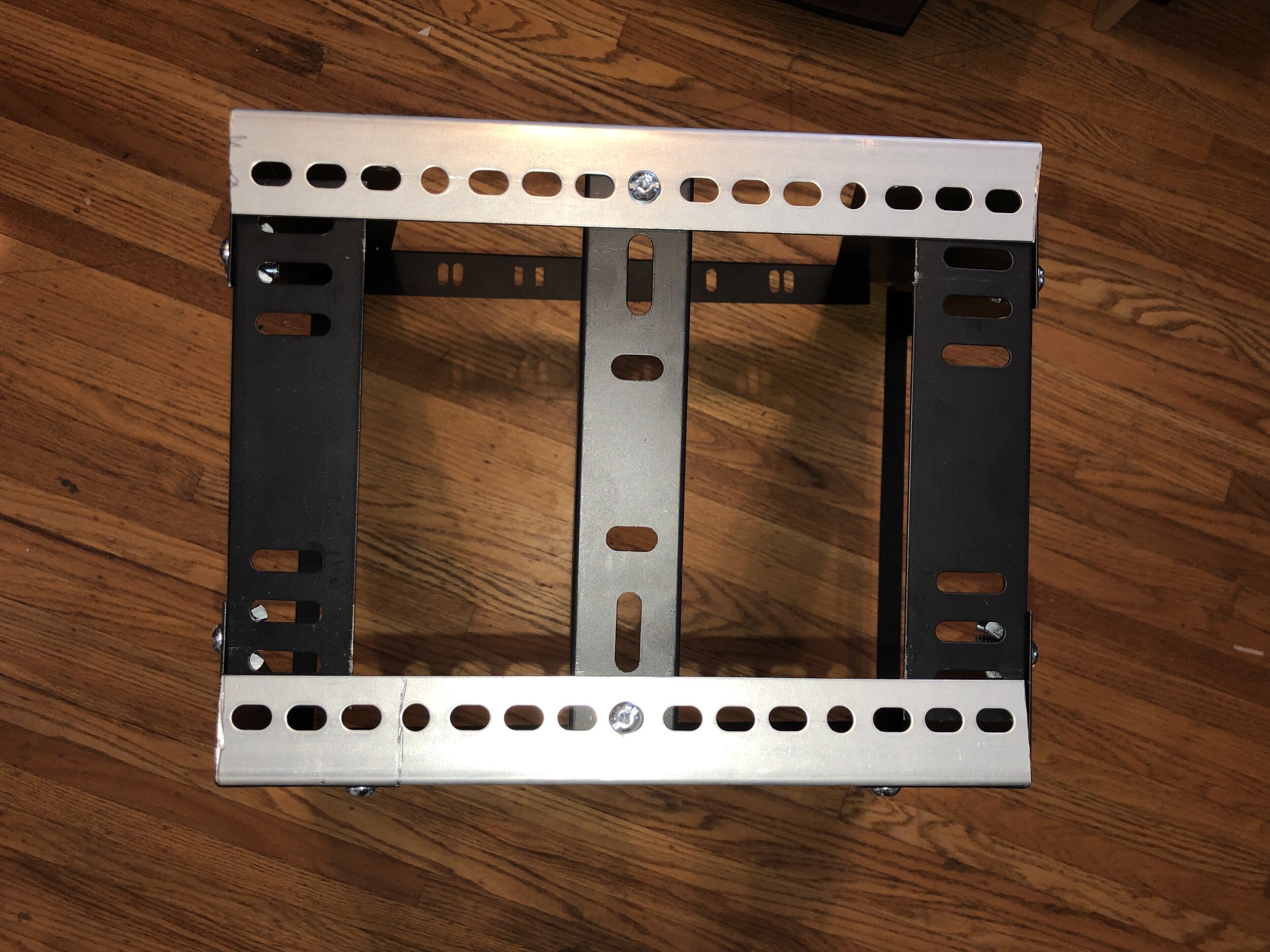

Today Oct 23, 2020 I decided to further enhance the three elbow joints near the top of the table. In each elbow is a screw holding the elbow together but with metal on metal if the screw slightly loosens it adds to undesirable table movement.

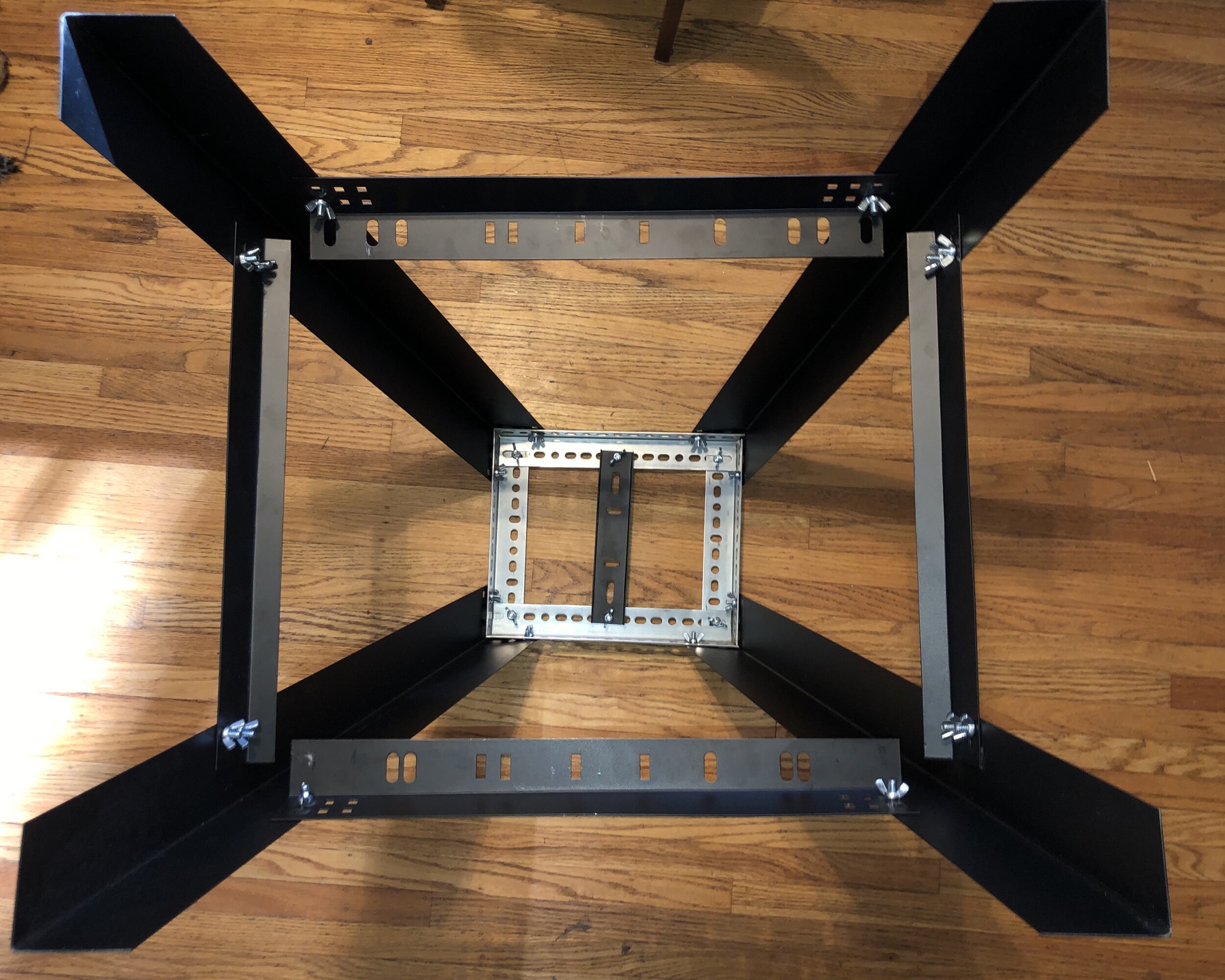

Extending my travel table to standing height - the “NZAK Multi-Machine stand”

November 2019 I added easy custom horizontal segments to upgrade this table’s usability and today I better secured the elbow joints and installed the three further leg extensions to take the 30” height to a perfect 39” inch. I don’t always use the modified components I made but they’re great when used.

The original table alone weighs slightly over 6lbs and easily dismantles although this option isn’t low cost CAD$420.56 (noted March 2021)+$78.16 - however sometimes one has to invest in the better options. Table supplies are hit and miss so check back regularly - see Hokitika Sock World - New Zealand on the NEW CSM MACHINES page.

This table wobbled a bit when setup as the screws in the three elbows loosened with use but with a little removable lock-tight all is awesome again. This table allows for a minimal pack up and event go - I’ve gone with a backpack and my machine in a box. Easy.

For more table info see my INDEX page under that category.

*Be prepared to buy rubber feet for this table from the hardware store as they are not provided.

REFERENCES: Instagram: 1, 2,